- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

/

-

CrO Content (%):

-

/

-

SiC Content (%):

-

/

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Chromium-Zirconium Mullite fire brick

-

Brand Name:

-

YuanDongLi

-

Size:

-

Customers' Requirement

-

Quality:

-

High

-

Raw material:

-

Chromium/Zirconium/Mullite

-

Bulk density (g/cm3):

-

≥ 2.95

-

Bulk density (lbs/ft3):

-

≥ 183.40

-

Cold Crushing Strength (MPa):

-

≥ 90

-

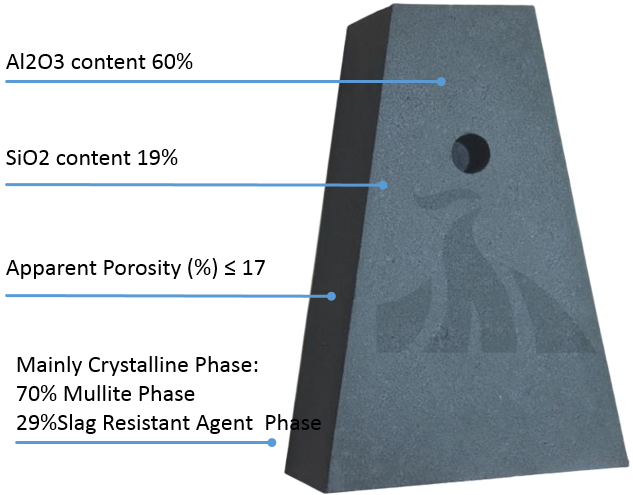

Apparent Porosity (%):

-

≤ 17

-

Application:

-

blast furnace, glass kiln, cement kiln and so on

Quick Details

-

SiO2 Content (%):

-

≤ 20

-

Al2O3 Content (%):

-

≥ 60

-

MgO Content (%):

-

/

-

CaO Content (%):

-

/

-

CrO Content (%):

-

/

-

SiC Content (%):

-

/

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Chromium-Zirconium Mullite fire brick

-

Brand Name:

-

YuanDongLi

-

Size:

-

Customers' Requirement

-

Quality:

-

High

-

Raw material:

-

Chromium/Zirconium/Mullite

-

Bulk density (g/cm3):

-

≥ 2.95

-

Bulk density (lbs/ft3):

-

≥ 183.40

-

Cold Crushing Strength (MPa):

-

≥ 90

-

Apparent Porosity (%):

-

≤ 17

-

Application:

-

blast furnace, glass kiln, cement kiln and so on

Product Paramenters

|

Index

|

Chromium-Zirconium Mullite Brick

|

|

Al2O3 (%)

|

≥ 60

|

|

SiO2 (%)

|

≤ 20

|

|

High Temperature Slag Resistant Agent

|

≥ 19

|

|

Cold compressive strength (MPa)

|

≥ 90

|

|

Apparent porosity (%)

|

≤ 17

|

|

Bulk Density (g/cm3)

|

≤ 2.95

|

|

Bulk Density (lbs/ft3)

|

183.40

|

|

(0.2Mpa,0.6%)Load softening began to temperature °C

|

>1700

|

|

Thermal shock Resistance (1100°C )

|

≥ 15

|

|

Mainly Crystalline Phase

|

Mullite Phase > 70%

|

|

|

High Temperature Slag Resistant Agent Phase > 27%

|

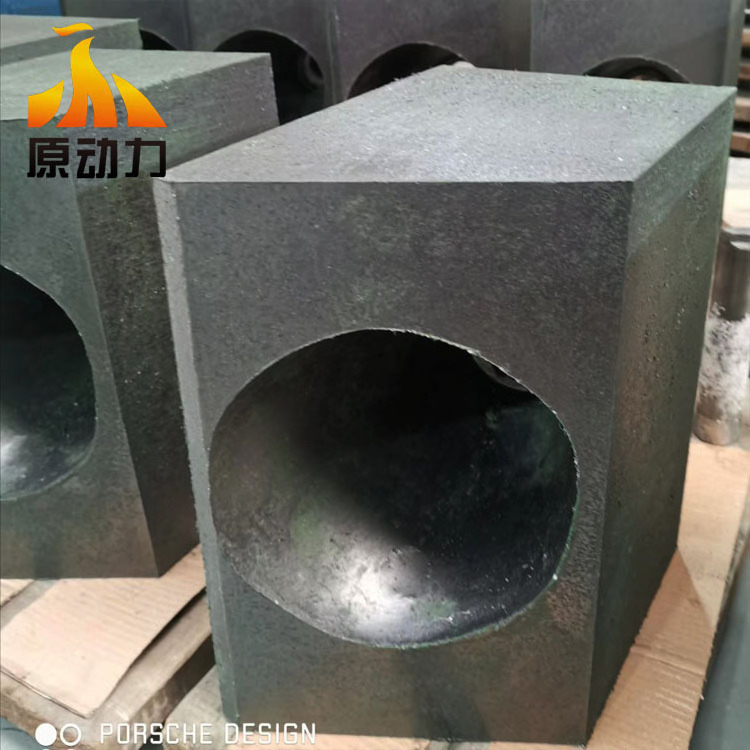

Specification

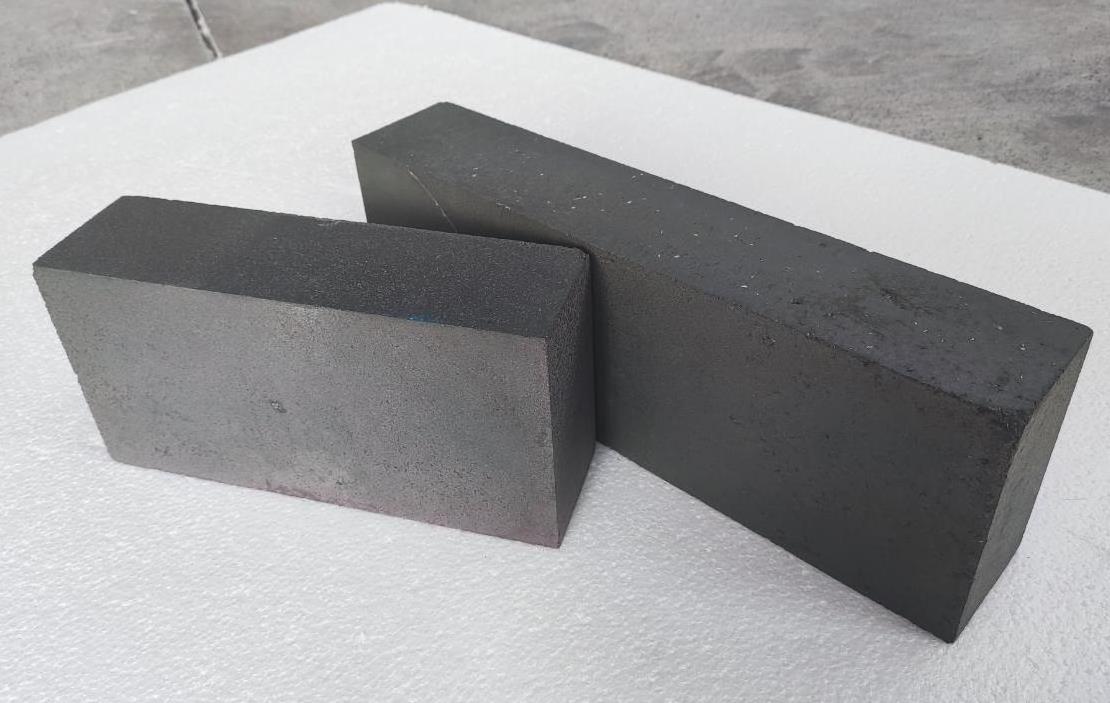

Chromium-Zirconium Mullite Brick

is a type of refractory brick that is produced through a sintering process. It is made from a combination of high-purity corundum and mullite grains, which are carefully selected for their excellent thermal and mechanical properties.

The manufacturing process of sintered corundum mullite brick involves carefully proportioning the corundum and mullite raw materials, followed by high-temperature sintering at around 1600-1800°C. This process promotes the formation of strong chemical bonds between the raw materials, resulting in a dense and highly durable brick structure.

Corundum is a crystalline form of aluminum oxide (Al2O3) known for its exceptional hardness, high melting point, and chemical stability. Mullite, on the other hand, is a compound of aluminum oxide and silicon dioxide (Al2O3·SiO2), which exhibits excellent thermal shock resistance and high refractoriness.

Chromium-Zirconium Mullite Brick

High temperature resistance:

The combination of corundum and mullite provides the brick with exceptional resistance to high temperatures. It can withstand temperatures up to 1800°C, making it suitable for applications in demanding industrial furnaces and kilns.

Good thermal shock resistance

:

The combination of chromium zirconium mullite and mullite phases in the brick provides it with excellent thermal shock resistance. It can withstand rapid temperature changes without cracking or spalling, making it suitable for applications that involve thermal cycling.

Corrosion resistance:

This brick has excellent resistance to corrosion and chemical attack. The inclusion of chromium oxide enhances its resistance to acidic and alkaline environments, making it suitable for applications in industries where harsh chemical conditions are present, such as petrochemical, chemical, and metallurgical processes.

Low thermal conductivity:

Chromium zirconium mullite brick has low thermal conductivity, which helps to reduce heat loss and improve energy efficiency in high-temperature applications. It allows for better heat insulation, resulting in more effective heat containment within furnaces and kilns.

High mechanical strength:

Chromium zirconium mullite brick possesses good mechanical strength, ensuring its durability and resistance to mechanical stresses, abrasion, and impact. It can withstand the physical demands of industrial processes and maintain its structural integrity over extended periods.

Chromium-Zirconium Mullite Brick

finds applications in various industries, including steel, non-ferrous metals, glass manufacturing, ceramics, and incineration plants. Typical applications include the linings of furnaces, kilns, reactors, and other high-temperature equipment where resistance to heat, corrosion, and thermal shock is essential.

Shapes and sizes: there are great variety of formats and shapes which are available for different forming and special machine processes.

The application effect of chrome corundum bricks produced by our factory on the tongue arch of soluble glass kilns for 8 years.

The effect picture of the chrome corundum brick produced by our factory has been used in the glass furnace using Petroleum coke as raw material for 8 years.

Recommend Products

Hot Searches