- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Corey

-

Power:

-

55kw to 164kw

-

Dimension(L*W*H):

-

As per different model

-

Weight:

-

10000 kg

-

Product name:

-

Concrete Mixing Plant

-

Keyword:

-

Concerete Batch Plant

-

Capacity:

-

60m3/h

-

Type:

-

Building Construction Tools

-

Name:

-

Belt Conveyor Harga Concrete Batching Plant

-

Application:

-

Building Works

-

Batching Machine:

-

PLD1600 Batching Machine

-

Model:

-

YHZS60/90/120

-

Local Service Location:

-

Pakistan

-

Productivity:

-

60-120m3/h

Quick Details

-

Machine Type:

-

Production line

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Corey

-

Power:

-

55kw to 164kw

-

Dimension(L*W*H):

-

As per different model

-

Weight:

-

10000 kg

-

Product name:

-

Concrete Mixing Plant

-

Keyword:

-

Concerete Batch Plant

-

Capacity:

-

60m3/h

-

Type:

-

Building Construction Tools

-

Name:

-

Belt Conveyor Harga Concrete Batching Plant

-

Application:

-

Building Works

-

Batching Machine:

-

PLD1600 Batching Machine

-

Model:

-

YHZS60/90/120

-

Local Service Location:

-

Pakistan

-

Productivity:

-

60-120m3/h

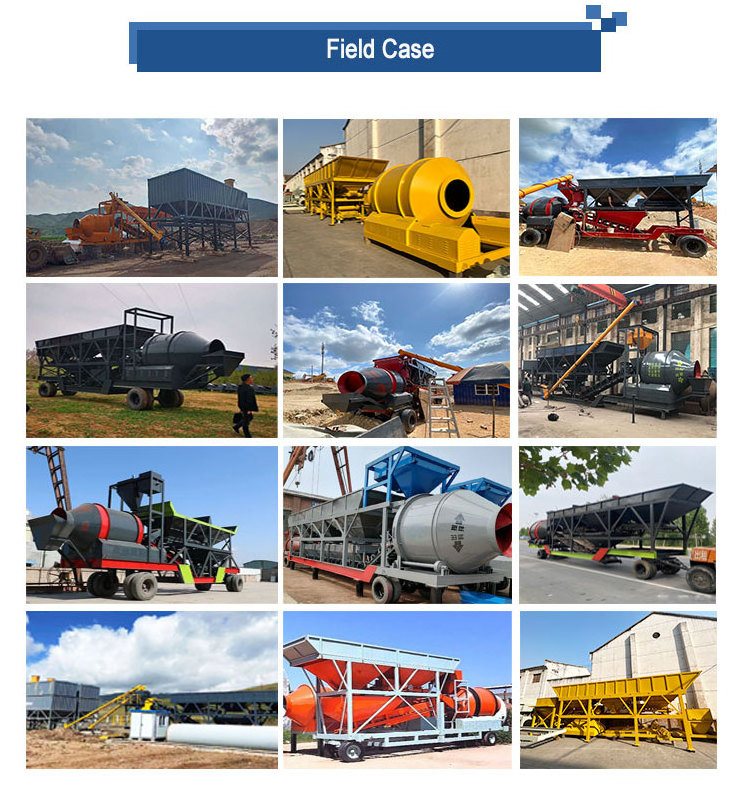

Full-automatic drum type mobile compact batching plant

The drum mobile concrete mixing plant is a concrete production equipment that integ-ates the material storage, weighing, conveying, mixing, unloading and automatic con-trol systems of the concrete mixing plant into a trailer unit.Suitable for roads, DAM, Bridges, commercial and residential projects.

Application scenario

Advantages:.

The complete set of machine equipment has a compact structure, gathering the entire process of concrete manufacturing, including feeding, weighing, and mixing, on a single trailer chassis..The computer software operation is simple and clear, with stable and reliable perform-ance, making the equipment suitable for various harsh environments..It is easy to transport as the mobile mixing plant is equipped with tires, towing hitches, driving data signal transmission devices, and brake systems. One towing vehicle is generally sufficient to complete the site conversion work..It occupies a small footprint and can be assembled quickly. It takes 2-3 days to complete assembly and be put into production, and disassembly is also convenient and can be done in 1 day..The mobile concrete mixing plant adopts a double horizontal shaft forced mixer, which has strong mixing capacity and can quickly and evenly mix various types of concrete.

Product Details

Main Engine

The piping design of the thickened barrel body makes the easily worn parts thicker.

Automated Program

Monitor the status of equipment in real time in many directions.

Measuring System

The fault rate is low, the performance is

stable and the measurement is accurate.

Distributing Bin

The ingredients are mixed in multiple ware-houses, and the mixing effect is good.

Weighing System

It is all accurately weighed, and the ratio is more accurate.

Thickened Material

All of them are made of manganese steel, which is strong and not easy to deform.

The split combination has the advantages of quick installation and convenient transition, and can be pulled away as needed.

Factory Show

We are specialized in manufacturing all kinds of concrete mixing plant factories, do export more than 12 years, choose us you can quickly get the product quotation, there is no middleman to earn the price difference, the price is going to make you satisfied, we have professional engineering technicians responsible for the installation of your products to guide and lifelong after-sales service. Welcome to visit our factory!

Product Parameters

|

Model

|

|

|

YHZM25-2

|

YHZM35-3

|

YHZM50-3

|

YHZM75-3

|

YHZM100-4

|

|||||

|

Theory capacity

|

|

m³/h

|

25

|

35

|

50

|

75

|

100

|

|||||

|

Discharging height

|

|

mm

|

1300

|

|

|

|

|

|||||

|

Total power

|

|

kw

|

42

|

46

|

60

|

67

|

77.5

|

|||||

|

Total weight

|

|

T

|

12

|

13

|

14

|

15

|

26

|

|||||

|

Mixing System

|

Model of Mixer

|

|

JZM500

|

JZM750

|

JZM1000

|

JZM1500

|

JZM2000

|

|||||

|

|

Mixing motor

|

kw

|

4.5kw*2

|

5.5kw*2

|

11kw*2

|

11kw*2

|

15kw*2

|

|||||

|

|

Discharging volume

|

L

|

500

|

750

|

1000

|

1500

|

2000

|

|||||

|

Aggregate System

|

Model of Batcher

|

|

PLD800-2

|

PLD1200-3

|

PLD1600-3

|

PLD2400-3

|

PLD3200-3

|

|||||

|

|

Aggregate Storage

|

|

4m³*2

|

5.5m³*3

|

6m³*4

|

8.5m³*5

|

14m³*4

|

|||||

|

|

Max.Aggregate Dia

|

mm

|

60/80

|

|

|

|

|

|||||

|

Measure ment System

|

Cement weight

|

kg

|

500

|

500

|

560

|

900

|

1200

|

|||||

|

|

Water weight

|

kg

|

220

|

220

|

220

|

330

|

400

|

|||||

|

|

Additive weighing

|

kg

|

30

|

30

|

30

|

40

|

50

|

|||||

|

Trailer Speed

|

|

Km/h

|

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

|||||

|

Optional cement silo

|

|

T

|

50/100

|

50/100

|

50/100

|

50/100

|

50/100

|

|||||

If you don't know how to choose the model, you can

click here to contact us

, professional sales team will recommend the most suitable for you!

Hot Searches