- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/380v

-

Power:

-

according to the capacity

-

Weight:

-

KG

-

Dimension(L*W*H):

-

according to the capacity

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

20 to 1000 tpd

-

Spare part:

-

1 Year Spare Part

-

Application:

-

White Rice Processing

-

Type:

-

Rice Mill Production Line

-

Color:

-

Custumer Request

-

Function:

-

Produce Rice

-

quality:

-

European standard

-

payment terms:

-

T/T

-

feature:

-

high yield

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HNLY

-

Production Capacity:

-

99%

-

Voltage:

-

220v/380v

-

Power:

-

according to the capacity

-

Weight:

-

KG

-

Dimension(L*W*H):

-

according to the capacity

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

20 to 1000 tpd

-

Spare part:

-

1 Year Spare Part

-

Application:

-

White Rice Processing

-

Type:

-

Rice Mill Production Line

-

Color:

-

Custumer Request

-

Function:

-

Produce Rice

-

quality:

-

European standard

-

payment terms:

-

T/T

-

feature:

-

high yield

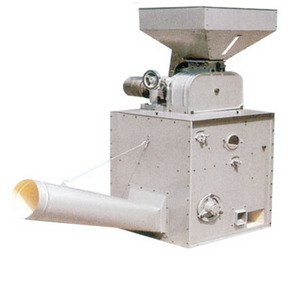

rubber roller rice huller 90% rice husking machine

Rice milling plant brief introduction:

1

. Advanced Craft.

The complete equipment adopts the new technology of dehulling before light grainding. In the traditional process, there are shells in the rice crushing and grinding uneven, The above questions are completely solved.

2.

Advanced Equipment.

The equipment is equipped with our efficient cleaning equipment, high efficiency dehulling equipment, new grinding equipment and efficient rice classification equipment. The application of these new technologies and equipments makes high yield, low broken increasment and rice with brighter color.

3.

Perfect Process.

The complete set of equipment from the raw grain cleaning, removing the stone, multi-stage dehulling, multi-stage grinding and polishing, to rice grading,packing and power distribution all realize automatic continuous operation, smooth process, easy operation and maintenance.

4.

Low Energy Consumption.

The set of complete sets of equipment are new models to avoid the traditional high energy consumption.

5.

Wide Application.

The equipment is widely applicable to large, medium and small rice processing plants and rice processing households in towns and villiages.

Flow Chart:

Paddy Cleaner → Destoner → Paddy husker → Paddy Separator → Rice Whitener → water polisher → Rice Grader → Color Sorter → Packing

Rice milling process:

|

Pre Cleaning |

Clean out all impurities and unqualified grains from raw paddy |

|

De-stoning |

Separate stones, clods from rice |

|

Parboiling (Alternative) |

I mprove the nutritious quality and milling recovery percent during husk ing, polishing, whitening |

|

Husking |

Remove husk from rice |

|

Husk Separation |

Separate husk from brown rice/ unhulled rice |

|

Rich Separation |

Separate the unhusked paddy from brown rice |

|

Whitening |

Remove all or part of the bran layer and germ from brown rice |

|

Polishing |

Improve appearance of milled rice by removing bran and by polishing kernel |

|

Color Sorting (Alternative) |

Remove foreign matter such as mould, broken rice from milled rice |

|

Milling |

Mill the pure rice |

Packaging

Packaging: all machines covered by plastic film firstly and then packed in wooden case to best protect the machine during long time transportation.

shipping

Shipping: All machines will be sent by sea, if you need other kind of transportation, please inform us in advance. And all machines would be shipped in 7 days after the receipt of payment. Before and after shipping, we will take photos of machines and send photos to client.

Our service

1. One year quality warranty for the machine and spare parts

2 . Overseas engineers service for installation

3 . Whole-life after-sales service and free consultation

4 . Customized requirements available

5 . Technician guide at the site.

6 . 24Hr online service