- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.1%

-

CrO Content (%):

-

0.1%

-

SiC Content (%):

-

0.1%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

SK32,SK34,SK33,DN12,DN14,DN17

-

Brand Name:

-

Topower

-

Product name:

-

Refractory fireclay brick

-

Refractoriness / C:

-

32/33/34

-

Color:

-

clay fire brick

-

Keyword:

-

clay fire refractory brick

-

Apparent Porosity:

-

23%~26%

-

Bulk Density:

-

2.0~2.2g/cm3

-

Cold crushing strength:

-

20~35MPa

-

Feature:

-

High Temperature Resistant

-

Usage:

-

Furnace Liner

-

Application:

-

Industrial Furnaces

Quick Details

-

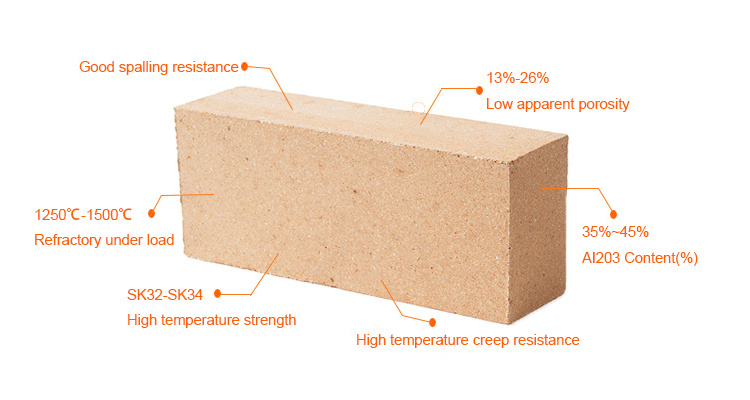

SiO2 Content (%):

-

52%

-

Al2O3 Content (%):

-

35%-45%

-

MgO Content (%):

-

0.1%

-

CaO Content (%):

-

0.1%

-

CrO Content (%):

-

0.1%

-

SiC Content (%):

-

0.1%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

SK32,SK34,SK33,DN12,DN14,DN17

-

Brand Name:

-

Topower

-

Product name:

-

Refractory fireclay brick

-

Refractoriness / C:

-

32/33/34

-

Color:

-

clay fire brick

-

Keyword:

-

clay fire refractory brick

-

Apparent Porosity:

-

23%~26%

-

Bulk Density:

-

2.0~2.2g/cm3

-

Cold crushing strength:

-

20~35MPa

-

Feature:

-

High Temperature Resistant

-

Usage:

-

Furnace Liner

-

Application:

-

Industrial Furnaces

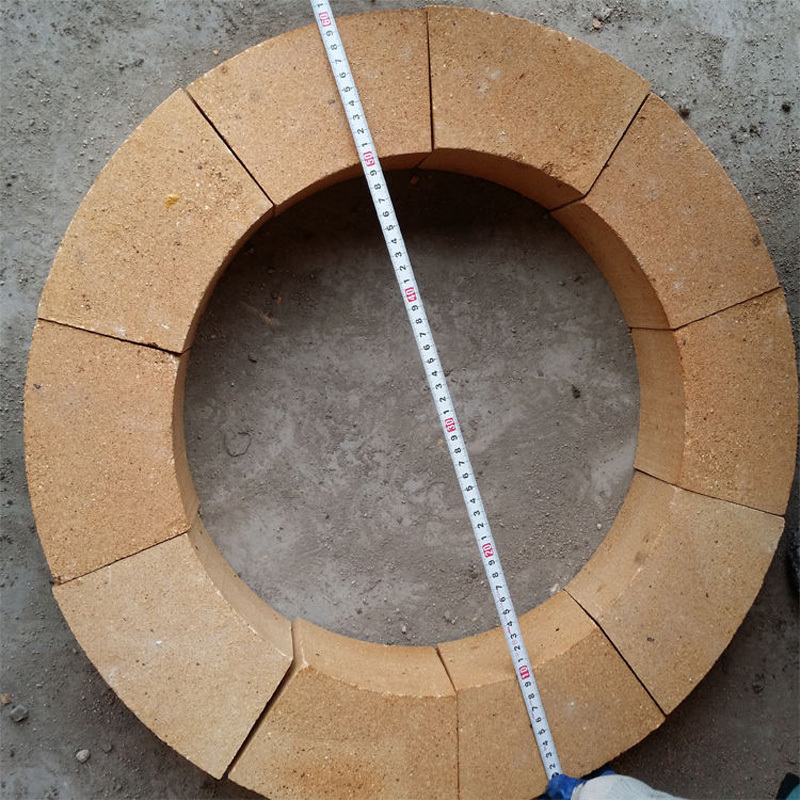

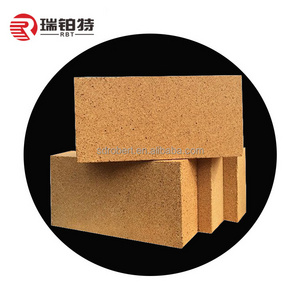

Fire clay brick Introduction

Fire clay brick refer to clay products with Al2O3 content of 30%~40%. The fire resistance can reach 1690~1730 ℃.

Refractory clay brick is made of clinker clay through mixing, molding, drying, sintering and proportioning. Alumina content in fireclay bricks approximate 28-55% are classified to Medium-duty Fireclay brick,High-duty Fireclay brick and Super-duty Fireclay brick.

We bring forth high quality fire clay Bricks, which is manufactured to meet the requirements of neutral refractoriness where safe working temperature is more than 1380 degree centigrade. We offer fire clay Bricks in different specifications as per customer requirements.

Product Paramenters

|

Brand

Properties

|

|

DN-12

|

DN-14

|

DN-17

|

SK-34

|

SK-33

|

SK-32

|

||||||

|

Refractoriness (SK)

|

|

35

|

34

|

34

|

34

|

33

|

32

|

||||||

|

Apparent Porosity (%)

|

|

12

|

14

|

17

|

23

|

24

|

26

|

||||||

|

Bulk Density (g/cm3)

|

|

2.40

|

2.34

|

2.25

|

2.20

|

2.15

|

2.00

|

||||||

|

Cold Crushing Strength (MPa)

|

|

70

|

65

|

50

|

35

|

30

|

20

|

||||||

|

Thermal Linear Expansion(%) @ 1,000℃

|

|

0.5

|

0.6

|

0.6

|

0.6

|

0.6

|

0.6

|

||||||

|

Permanent Linear Change (%)@ 1,400℃ x 2hrs

|

|

±0.1

|

±0.2

|

±0.2

|

±0.3

|

±0.5

|

±0.5

|

||||||

|

Refractoriness under Load (℃) @0.2MPa

|

|

1,500

|

1,470

|

1,430

|

1,350

|

1,300

|

1,250

|

||||||

|

Chemical Composition (%)

|

Al2O3

|

45

|

45

|

42

|

40

|

38

|

35

|

||||||

|

|

Fe2O3

|

1.3

|

1.5

|

1.7

|

2.0

|

2.2

|

3.0

|

||||||

|

Main Applications

|

|

- Reheating Furnace

- Blast furnace -Coke Oven,Torpedo Car, -Cement Rotary kiln, Various Rotary kiln, -Chemical Reactor, incinerator, Non Ferrous, metal Furnace, -Glass furnace -General Industrial Furnace etc. |

|

|

|

|

|

||||||

Recommend Products

Topower is the leading supplier of high-grade refractory products, systems and solutions which are indispensable for industrial high-temperature processes exceeding 1,200°C in a wide range of industries furnace, including steel, cement, non-ferrous metals and glass etc.

Q1 : Are you a manufacture or trader?

A1: We are truly a manufacturer, we not only can provide the high quality products with the best price, but also can offer the best pre-sale service and after-service.

Q2: How can you control your quality?

A2: TOPOWER have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods.

Q3 : Do you supply samples?

A3 : Of course, free samples are available.

Q4 : What is your lead time?

A4 : It usually needs about 15- 20 days after receiving the PO.

Q5 : Can we visit your company?

A5 : Yes, for sure, you are welcome to visit TOPOWER company and our products.

Also, we can talk more about the technique details if you need.

Q6 : What is the warranty of your products?

A6 : Our products have at least 1 year warranty,if any quality problems,

we will take responsibility of the cost of the shipment and the replacement.

Hot Searches