- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Nairy Machinery

-

Dimension(L*W*H):

-

4200*2600*3600mm

-

Weight:

-

7000 KG

-

Application:

-

Stone Sand Washing

-

Keyword:

-

Sand Washing Production Line

-

Advantage:

-

Sand stone washing grading

-

Function:

-

Screening\separation\washing\sieving

-

After Sale Service:

-

Life-long Service

-

Quality:

-

High Level

-

Feeding size(mm):

-

0-10mm

-

Customization:

-

Accept Customization

-

Installation:

-

Engineers Guide

-

Structure:

-

helical

Quick Details

-

Marketing Type:

-

Manufactured in China

-

Capacity(t/h):

-

50-100

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Nairy Machinery

-

Dimension(L*W*H):

-

4200*2600*3600mm

-

Weight:

-

7000 KG

-

Application:

-

Stone Sand Washing

-

Keyword:

-

Sand Washing Production Line

-

Advantage:

-

Sand stone washing grading

-

Function:

-

Screening\separation\washing\sieving

-

After Sale Service:

-

Life-long Service

-

Quality:

-

High Level

-

Feeding size(mm):

-

0-10mm

-

Customization:

-

Accept Customization

-

Installation:

-

Engineers Guide

-

Structure:

-

helical

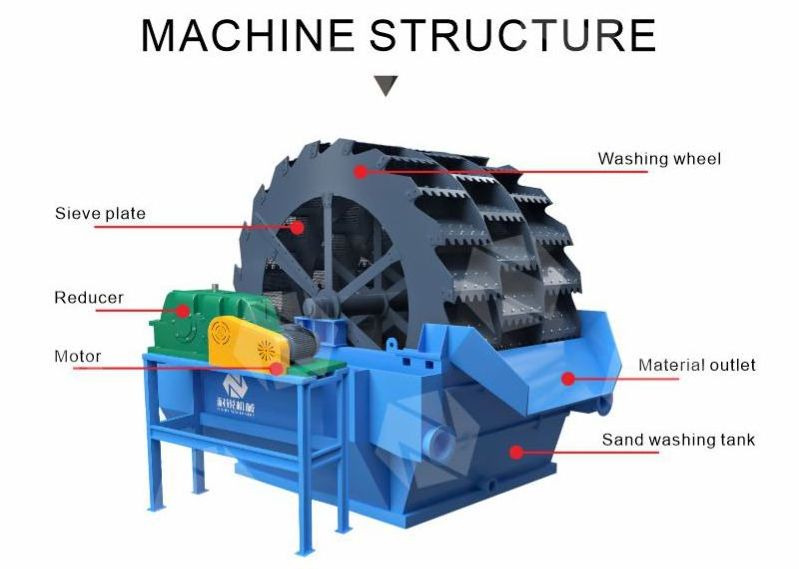

Product Overview

Sand Washing Machine Introduction

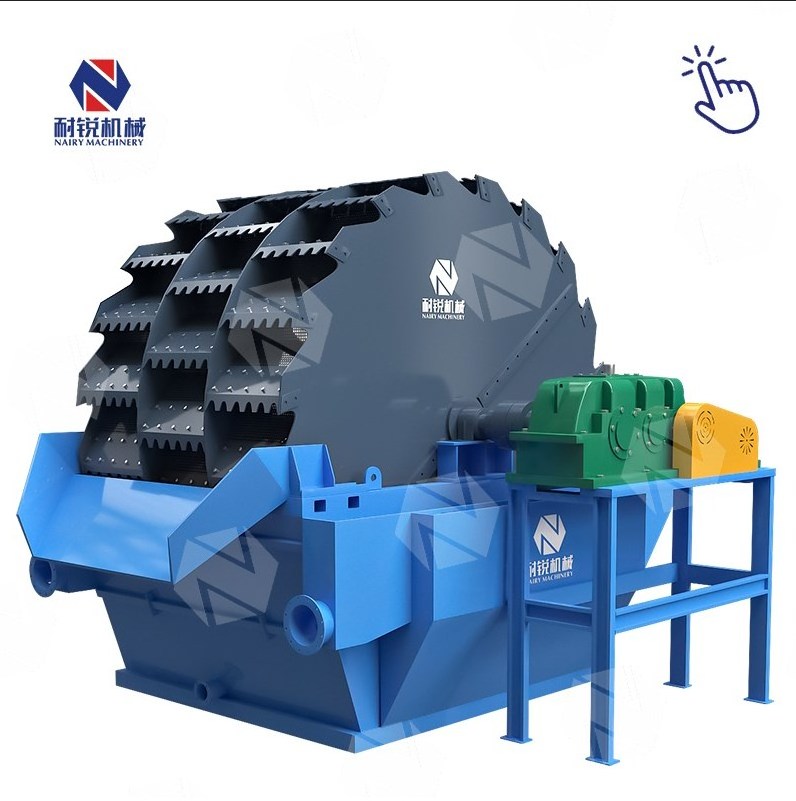

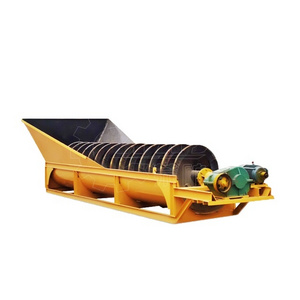

DX series wheel sand washing machine is a new-structure sand washing equipment developed by our company in combination with the operation situation of sand and stone industry at home and abroad and many years of practical experience. This machine is widely used in sand washing operations in the sand aggregate processing industry, which can effectively wash and remove the mixed stone powder and debris in the sand and improve the quality of the sand.

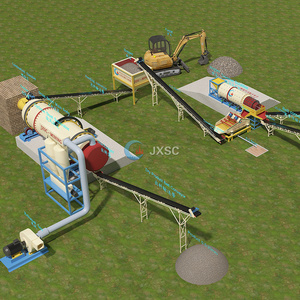

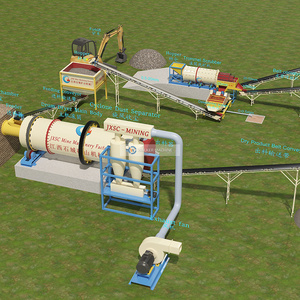

Sand Washing Machine Application

Fine stone powder, river sand, aggregates, artificial sand, basalt artificial sand, etc for washing, grading, and cleaning in building materials, utilities, and other industries.

Sand Washer Machine Features

1. DX series wheel sand washing machine has the advantages of high yarn recovery rate, reasonable product classification configuration, less mud content and large single processing capacity.

2. The combination design of manganese steel punching bar seam screen and discharge port wear-resistant high aluminum ceramics ensures the reliability of long-term operation of the equipment.

3. Scientific mesh structure design improves the cleanliness of sand washing.

4, unique overflow type drainage structure design, solve the problem of turbulence in operation, ensure classification efficiency, improve the recovery rate of fine sand.

5. Imported wear-resistant materials are sprayed on the tank body and heavily worn parts to ensure that the equipment will not be corroded or corroded within 5 years.

6, Bearing selection of ZSZ, SKF or NSK, motor selection of domestic famous brands or SIEMENS, WEG, to ensure the long-term reliable operation of the equipment.

Product Specifications

|

Model

|

Feed particle size(mm)

|

Recovered particle size (mm)

|

Capacity (t/h)

|

Power(Kw)

|

Dimension(mm)

|

Weight(Kg)

|

|

DX3015

|

|

|

50-100

|

5.5

|

4200*2600*3600

|

7000

|

|

DX3620

|

|

|

100-150

|

7.5

|

5200*3650*4000

|

7200

|

|

DX3624

|

|

|

120-200

|

11

|

5200*4000*4200

|

7800

|

|

DX4230

|

|

|

150-250

|

15

|

6500*4600*5000

|

9000

|

Important Reminder:

1. The technical parameters are for reference only.

2. The product quotation is for reference only, based on the purchased model and configuration.

3. For more information, please call or consult customer service.

Product Details

Application Case

Recommend Products

Hot Searches