- Product Details

- {{item.text}}

Quick Details

-

Certification:

-

ISO9001:2008

-

Application:

-

Marble Quarry

-

Advantage:

-

Wear Resistant

-

Packing:

-

Iron Pallet

-

Color:

-

Green

Quick Details

-

Weight (KG):

-

1900

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MANTLE

-

Certification:

-

ISO9001:2008

-

Application:

-

Marble Quarry

-

Advantage:

-

Wear Resistant

-

Packing:

-

Iron Pallet

-

Color:

-

Green

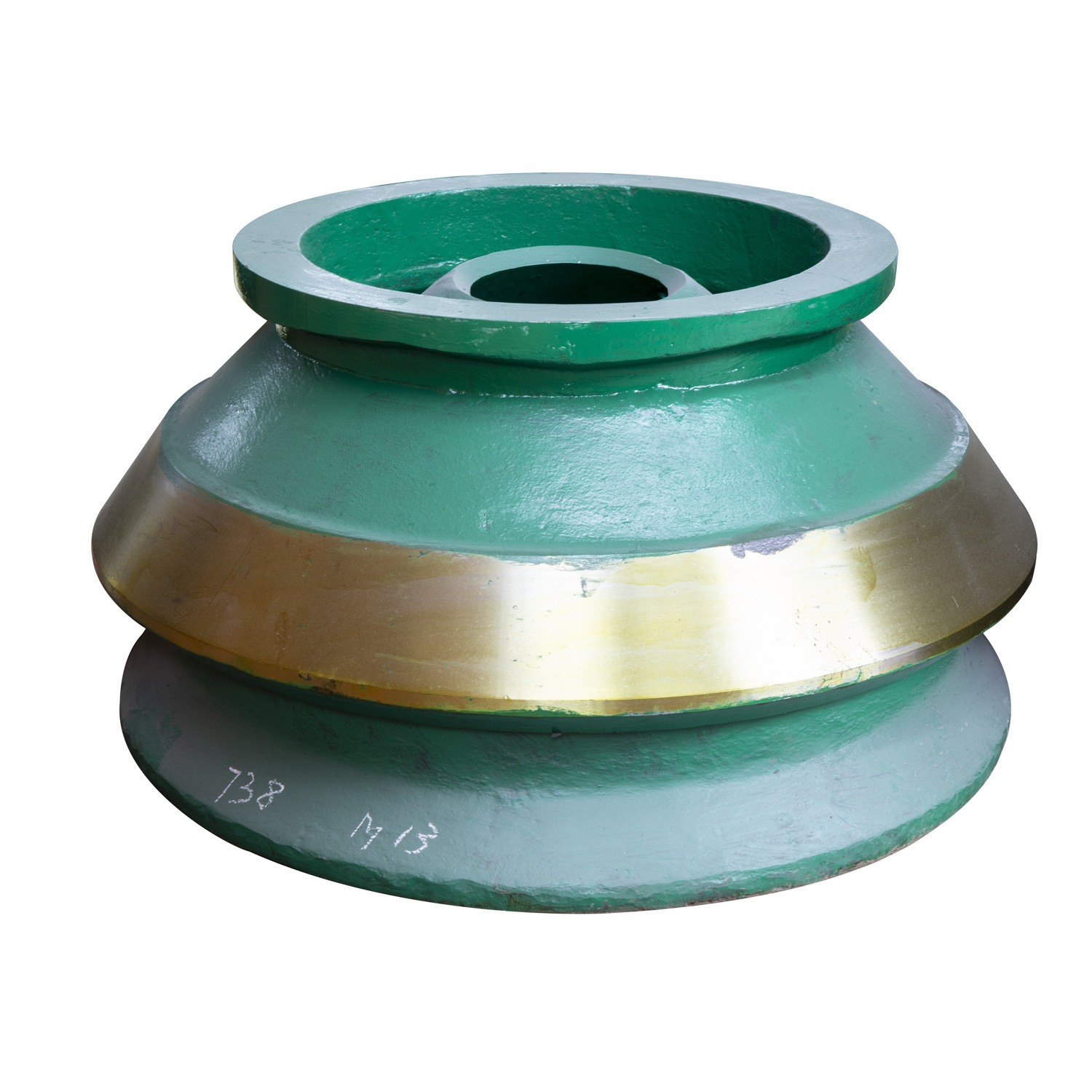

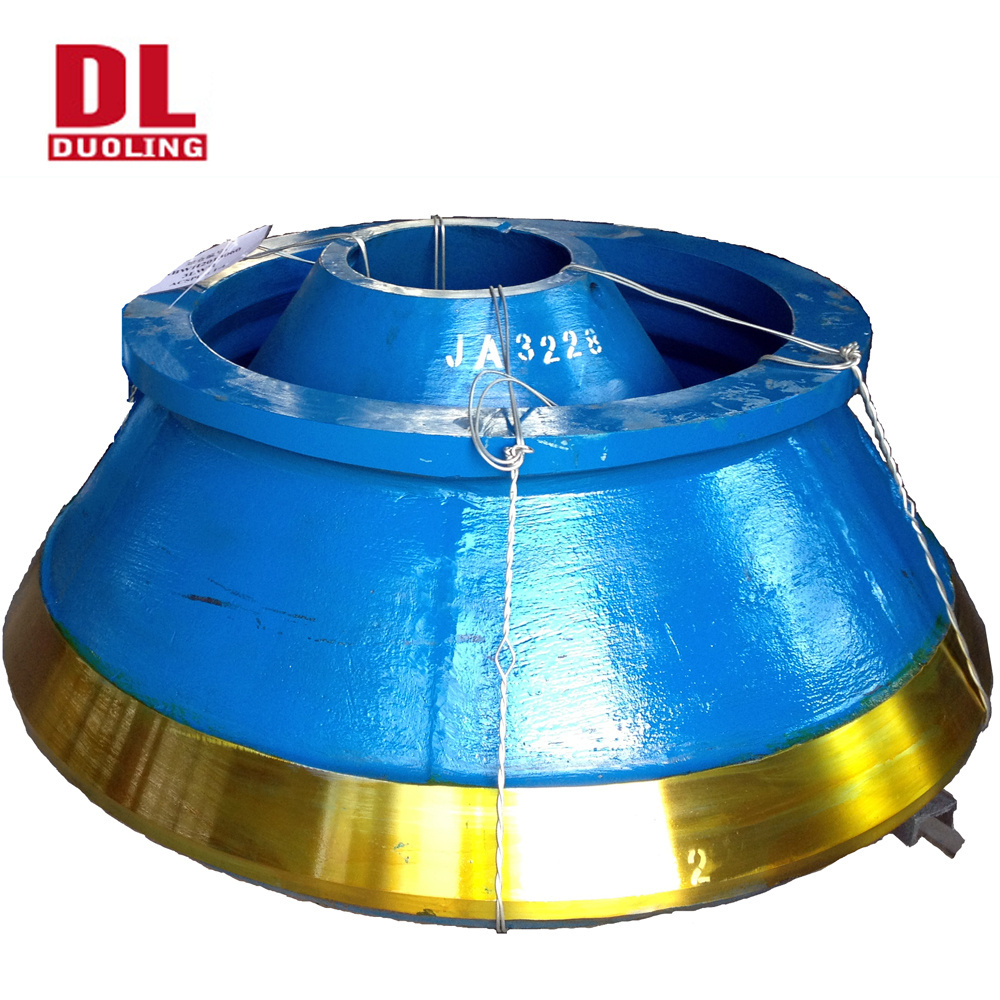

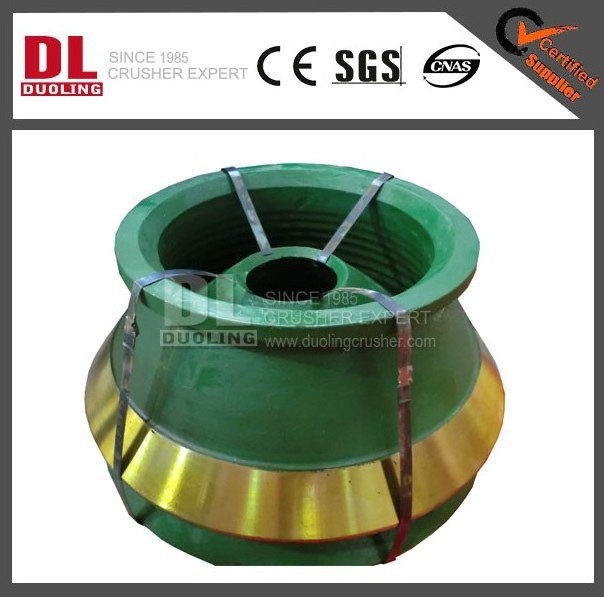

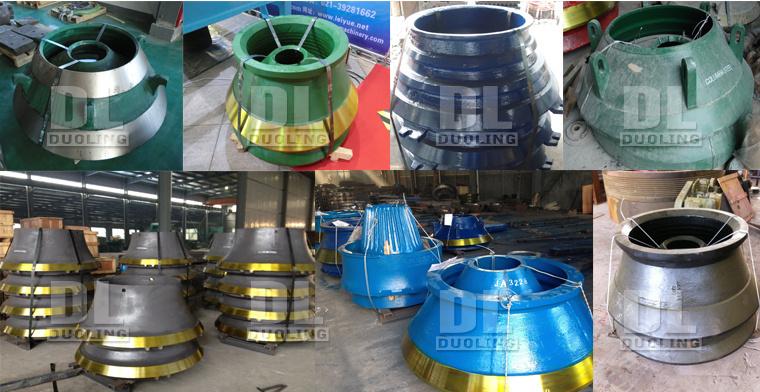

HP200 HP300 HP500 HP800 CONE CRUSHER SPARES MANTLE

Cone Crusher Parts is designed to protect the Cone Crusher, thus improves the working life.

We supply high qualified concave in high Cr, Mo, alloy steel for Cone Crusher.

Cone Crusher Parts

1. Spare parts for Cone Crusher.

2. Be used in manganese steel

3. We can do as per customer's requirements.

We manufacture an extensive range of wear and spare parts in China for the worlds most popular crushing brands, like the spare parts for the below crushers.

|

Crusher type |

Model |

Spare parts |

|

Cone crusher |

HP100, HP200, HP300, HP400, HP500, HP4, HP5, GP100, GP200, GP300, GP550, GP11 |

Bowl liner, mantle |

|

H2800, H3800, H4800, H6800, H7800, H8800, S2800, S3800, S4800, S6800 |

||

|

4FT .Standard, 4-1/4FT.Short head , 5-1/2FT.Standard |

Features:

1) Material : high manganese steel:Mn13Cr2, Mn18Cr2, etc;

2) Use : Machinery in metal recovery smash, mine, metallurgy, chemical industry, cement, petroleum etc.

3) Production quality testing : High frequency infrared carbon & sulfur analyzer, Metallographic microscope, Machinery performance testing equipment, Hardness testing equipment, Ultrasonic inspection equipment

4) Easy installation: The anti-abrasion block is a semi-permanent part, which is easy for replacement.

Chemical composition

|

Code Elem |

C |

Mn |

Si |

Cr |

Mo |

P |

S |

|

ZGMn13-1 |

1-1.45 |

11-14 |

0.3-1 |

- |

- |

≤0.09 |

≤0.04 |

|

ZGMn13-2 |

0.9-1.35 |

11-14 |

0.3-1 |

- |

- |

≤0.09 |

≤0.04 |

|

ZGMn13-3 |

0.9-1.35 |

11-14 |

0.3-0.8 |

- |

- |

≤0.09 |

≤0.04 |

|

ZGMn13-4 |

0.9-1.3 |

11-14 |

0.3-0.8 |

1.5-2 |

- |

≤0.09 |

≤0.04 |

|

ZGMn13-5 |

0.75-1.3 |

11-14 |

0.3-1 |

- |

0.9-1.2 |

≤0.09 |

≤0.04 |

Cone Crusher Liners pictures

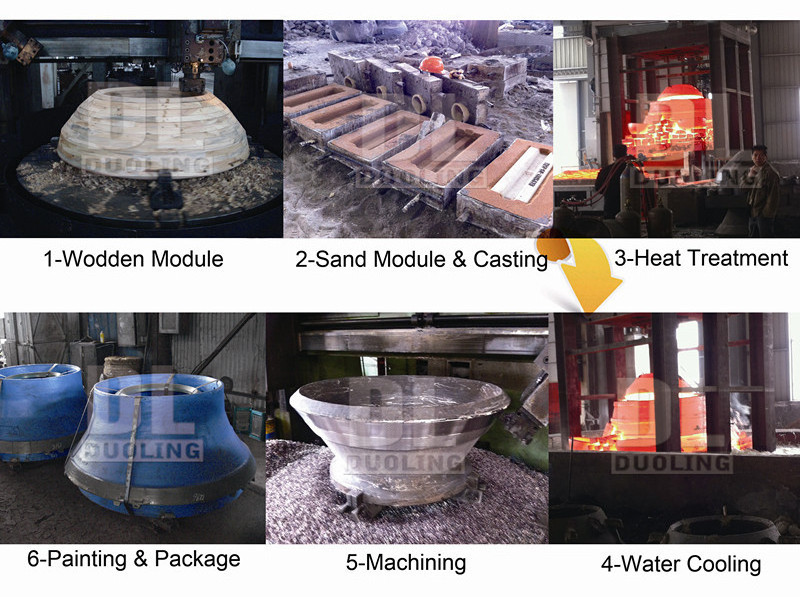

Production Process

Trying Us by Trial Order

1. +20 years of manufacturing experience is worth your trying

2. Our sincerity is worth your trying

Advantage:

1. MOQ: We stay poised for any demand, large quantity or small quantity to your needs

2. OEM: We can produce according to your drawing.

3. Service: We treat you as our friend, only one-mouse away

4. Quality: We have strict quality control system.

Order Guiding

1. Inquiry with your Drawing Number

2. Confirm the availability of the drawings under your number

3. Drawings to be made when not available

4. Confirm the price, lead time, artwork, payment term etc

5. Quotation based on drawings

6. Performa Invoice sent

7. Down payment paid and send your bank receipt

8. Production Process

9. Delivery- TT balance payment before shipment. Balance payment against B/L Copy or L/C is accepted. Inform the tracking number of the files expressed.

10. Order finished (only when you receive the goods and are satisfied with them)

11. Feedback about Quality, Service, Market Feedback & Suggestion. And we can do better in our future cooperation.

1. Why we have to choose you instead of others?

a) We have an increasing presence in the global market for more than 20 years-Reputation worth your trying

b) We have a profound accumulation in this field-Experience worth your trying

c) We have a strict self-inspection system-Quality worth your trying

d) Other than those, we need your confidence in us from a trial amount

2. How do we judge if you supply sufficient components for our parts?

A) As long as the material is chosen, we shall strictly manufacture the parts according to its range

B) We have equipments to carry out component percentage testing, for our long term business relationship, we

Our selves will implement strict procedures to get rid of your worries in this regard.

3. Will you accept factory inspection?

Yes. You are greatly welcome to our factory for your own inspection.