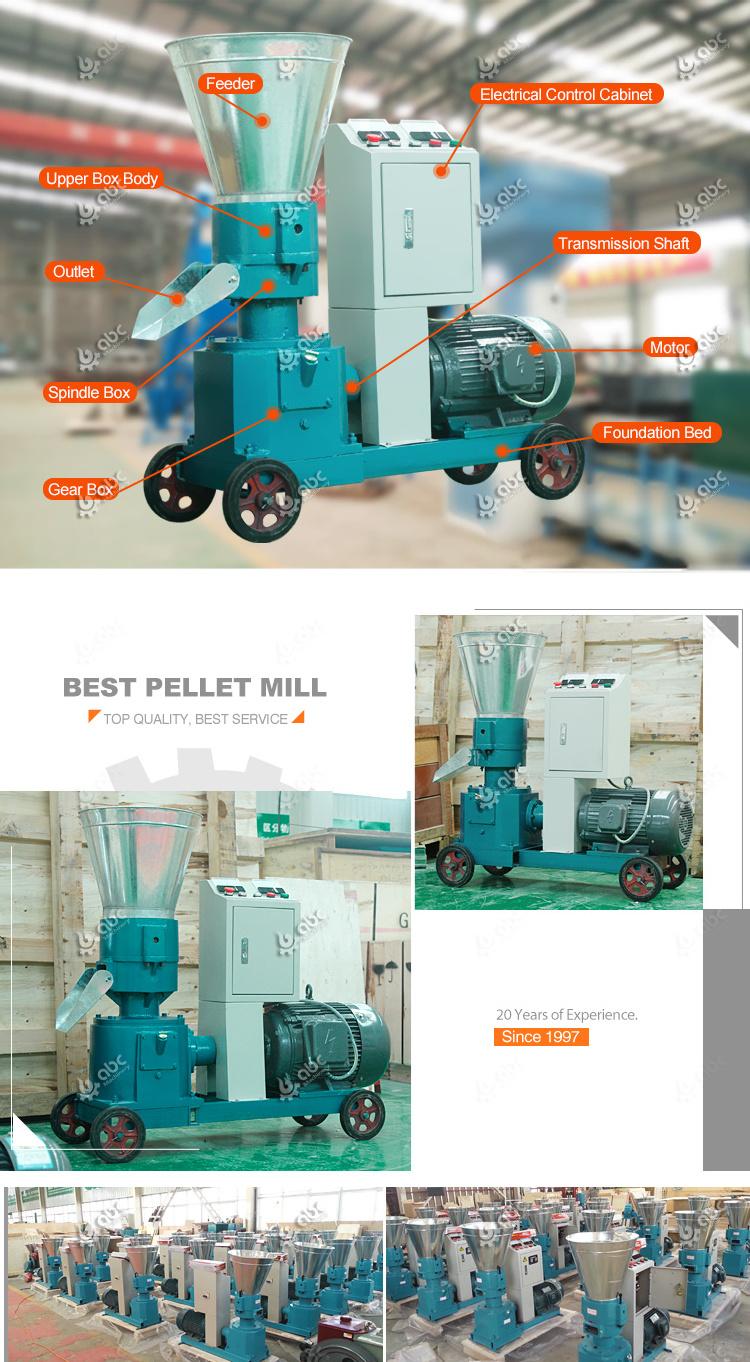

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Weight:

-

600 kg

-

Marketing Type:

-

Factory Direct Sales

-

Make Poultry Feed for:

-

Poultry,chicken,hen,rooster,layer,quail,bird,duck

-

Make Livestock Ruminant Feed:

-

cattle,cow,dairy,goat,sheep,horse,camel,pig,rabbit

-

Pellets Diameter:

-

Feed Mash, Crumbles 2.5mm,3/3.5/4/4.5/5/6/7/8mm

-

Make Fish Food for Other Features:

-

Press Floating/sinking feed for Fish,shrimp,trout

-

Processing Technology:

-

pelletizing,compacting,extruding,pressing,milling

-

Feed Production Process:

-

feed crushing/grinding,mixing,pelletizing,cooling

-

Related Feed Mill Equipment:

-

automatic feed crusher, mixer,extruder,granulator

-

Main Market:

-

Uzbekstan,Nigeria,Ghana,Zambia,Kenya,South Africa

-

Suitable Materials Final Products:

-

grass,straw,stalk,rice husk,maize,corn,fish meal

-

Small Feed Mill Output (kg per hour):

-

60kg/h80/100/200/300/400/500/600/800/1000/2000kg/h

Quick Details

-

Max. Capacity:

-

60-1000kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ABC Machinery

-

Voltage:

-

380V

-

Weight:

-

600 kg

-

Marketing Type:

-

Factory Direct Sales

-

Make Poultry Feed for:

-

Poultry,chicken,hen,rooster,layer,quail,bird,duck

-

Make Livestock Ruminant Feed:

-

cattle,cow,dairy,goat,sheep,horse,camel,pig,rabbit

-

Pellets Diameter:

-

Feed Mash, Crumbles 2.5mm,3/3.5/4/4.5/5/6/7/8mm

-

Make Fish Food for Other Features:

-

Press Floating/sinking feed for Fish,shrimp,trout

-

Processing Technology:

-

pelletizing,compacting,extruding,pressing,milling

-

Feed Production Process:

-

feed crushing/grinding,mixing,pelletizing,cooling

-

Related Feed Mill Equipment:

-

automatic feed crusher, mixer,extruder,granulator

-

Main Market:

-

Uzbekstan,Nigeria,Ghana,Zambia,Kenya,South Africa

-

Suitable Materials Final Products:

-

grass,straw,stalk,rice husk,maize,corn,fish meal

-

Small Feed Mill Output (kg per hour):

-

60kg/h80/100/200/300/400/500/600/800/1000/2000kg/h

TTT

ABC Machinery

is a leading manufacturer of

a

nimal feed processing machines, complete animal feed mill plant and other related equipment

for manufacturing

poultry feed, cattle feed, fish feed, etc.

Over 10 years of experience in equipment manufacturing and project construction has proved our strong ability and great product quality.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

↘

Hot Sale Main Types of Animal Feed Pellet Machine

⚙️

Ring Die Feed Pellet Mill:

Heavy duty feed making machine for large scale feed production.

⚙️ Fish Feed Extruder Machine: It is also called floating fish feed machine, which is specially designed for making floating fish feed pellets, and slow-sinking feed. (floating fish feed making machine, fish pellet making machine)

⚙️ Complete Feed Milling Plant: Offer both mini/small animal feed plant or movable/ portable wood pellet machine /mobile small feed mill plant (800kg/h~1000kg/h for small business) and customzied full pellet line for industrial turnkey fish/cattle/poultry feed plant, including both mash feed, pellet feed and feed crumbles . The capacity of our animal feed production line ranging from 1ton to 100 tons per hour (to ns/h) for fully pellet feed production line.

Motor-driven Type (Model SZLSP-D-B-C)

|

Model

|

Power (kw)

|

Output (kg/h)

|

Weight (kg)

|

Package Size (mm)

|

|

ZLSP 120B

|

3

|

60-100

|

80/100

|

750x320x680

|

|

ZLSP 150B

|

4kw

|

90-120

|

95/110

|

800x450x700

|

|

ZLSP 200B

|

7.5kw

|

200-300

|

200/230

|

1650x820x1200

|

|

ZLSP 230B

|

11kw

|

300-400

|

290/320

|

1050x480x930

|

|

ZLSP 260B

|

15kw

|

400-600

|

320/360

|

1180x540x1000

|

|

ZLSP 300B

|

22kw

|

600-800

|

350/380

|

1240x540x950

|

|

Model

|

Power (kw)

|

Output (kg/h)

|

Weight (kg)

|

Package Size (mm)

|

|

ZLSP 150C

|

4kw

|

90-120

|

105/125

|

1000x480x780

|

|

ZLSP 200C

|

7.5kw

|

200-300

|

210/230

|

1050x550x830

|

|

ZLSP 230C

|

11kw

|

300-400

|

290/320

|

1200x560x950

|

|

ZLSP 260C

|

15kw

|

400-600

|

340/370

|

1240x580x1000

|

|

ZLSP 300C

|

22kw

|

600-800

|

420/465

|

1300x620x1100

|

↘

BEST Feed Machine for Different Kinds of Animals

☑ Livestock & Ruminant:

Cattle, cow, dairy, sheep, goat, horse, alpaca, antelope, camel, deer, pig, rabbit, etc. (as livestock

feed machine, cattle feed production line)

feed machine, cattle feed production line)

☑ Aquatic Animals: Fish, herring, carp. mandarin fish, tilapia, catfish, yellow catfish, channel catfish, dace, dory, rainbow

trout, shrimp, crab, etc. (as fish feed pellet machine, floating fish feed extruder machine)

↘ Why Choose Us?

☑

Business Cooperation All Over the World:

Our AAA have sales, service and engineering operations around the world, cooperate with more than 50 countries, while providing localized services.

☑

Advanced Processing Equipment, Quality Assurance:

Imported domestic and foreign CNC equipment with high processing precision. Each process in the production workshop is strictly trained according to standardized criteria, and the chief engineer personally manages the process during the production process to ensure product quality.

↘

Offer Customized

AAA

& Complelte Business Plan

(Feed Mash / Feed Pellets / Feed Crumbles)

⭐

Energy Feed: Cereals, corn/maize, grain, bran, starchy roots and tubers, grass seeds and trees, dregs.

⭐

Protein Feed: Fish meal, silkworm pupae, bone meat meal, meat meal, feather meal, blood meal, earthworms, slaughter scraps, fly maggots and single-cell protein feed (yeast type).

⭐ Roughage: Hay, straw, rice husk, peanut stalk, agricultural by-products and dregs with crude fiber content of 18% or more in dry matter, leaves, etc.

⭐ Green Juicy Feed: Including forage, lucerne, alfalfa, green grass, leafy vegetables, non-starchy roots and fruits, water

plants, etc. Not considering the crude protein and crude fiber content after folding and drying.

⭐ Silage Feed: Fresh natural plant feed made of silage and silage with appropriate amount of bran or other additives, including semi-dry silage with moisture content of 45%-55%.

⭐ Mineral Feed: Mineral feed refers to natural minerals and chemically synthesized inorganic salts available for feeding. Shell and bone meal from animals, but mainly used to provide mineral nutrition, also classified as such.

⭐ Vitamin Feed: Including industrial synthesis or purification from raw materials to refine a variety of single vitamins and

mixed multivitamins, but natural feed rich in vitamins is not classified as vitamin feed.

⭐ Feed Additive: Additives are a variety of non-nutritive additives used to strengthen the feeding effect, with the feed

production and storage of non-nutritive raw materials and their formulated products. Such as a variety of antibiotics,

antioxidants, mold inhibitors, binding agents, coloring agents, flavor enhancers, and health care and metabolic regulation of drugs.

Animal feed can also be divided into full price compound feed, concentrated feed, premix feed, concentrate mixed feed and mixed feed.

↘ Hard Feed Pellets Making Process (without puffing/extruding)

The process flow of automatic cattle/poultry feed machine line: raw material receiving and storage, cleaning (debris removal), crushing, batching, mixing, pelletizing (livestock/poultry feed mill machine), cooling, grading, finished product packaging storage and distribution.

↘ Extruded Feed Granules (Puffing/Extrusion)

The process flow of commercial pet/fish feed mill plant: First batching, then crushing, then micro crushing, mixing,

puffing/extruding (fish food pellet machine), drying, cooling, grading and packaging/bagging.

The process flow of commercial pet/fish feed mill plant: First batching, then crushing, then micro crushing, mixing,

puffing/extruding (fish food pellet machine), drying, cooling, grading and packaging/bagging.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

↘

Successful Projects

of Complete Animal Feed Pellet Plant

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Hot Searches