- Product Details

- {{item.text}}

Quick Details

-

Power:

-

220-480

-

Weight (KG):

-

300 kg

-

Product name:

-

Sludge Dewatering Screw Press Machine

-

Sludge Flow Treating Capacity:

-

0.2 - 105m3/hr

-

DS Treating Capacity:

-

5 - 650kgds/hr

-

Inlet SS Concentration:

-

0.5% - 6%

-

Outlet cake moisture content:

-

75% - 85%

-

Motor:

-

SEW/NISSEI/Customize

-

Electrical component:

-

Schneider/Omron/Customize

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

NORSEN

-

Size:

-

1830*756*1150 mm

-

Power:

-

220-480

-

Weight (KG):

-

300 kg

-

Product name:

-

Sludge Dewatering Screw Press Machine

-

Sludge Flow Treating Capacity:

-

0.2 - 105m3/hr

-

DS Treating Capacity:

-

5 - 650kgds/hr

-

Inlet SS Concentration:

-

0.5% - 6%

-

Outlet cake moisture content:

-

75% - 85%

-

Motor:

-

SEW/NISSEI/Customize

-

Electrical component:

-

Schneider/Omron/Customize

-

After Warranty Service:

-

Video technical support

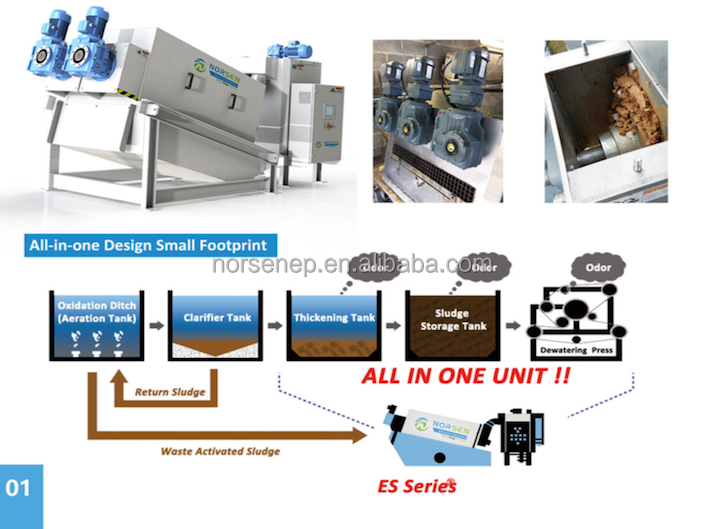

The spiral type sludge dewatering machine is a kind of water treatment system, which is widely used in municipal wastewater treatment engineering, petrochemical, light industry, chemical fiber, paper making, pharmaceutical, leather, and other industries.

The actual operation shows that the sludge dewatering can create considerable economic benefits and social benefits for the customers.

The actual operation shows that the sludge dewatering can create considerable economic benefits and social benefits for the customers.

Advantages:

1. Automatic continuous operation

2. Compact design with flocculation and dewatering

3. Low power and water consumption

3. Low power and water consumption

4. Low operation cost

5. No filter cloth, no clogging

6. No need for sludge thickener

5. No filter cloth, no clogging

6. No need for sludge thickener

7. Easy operation and maintenance

8. No vibration and noise

8. No vibration and noise

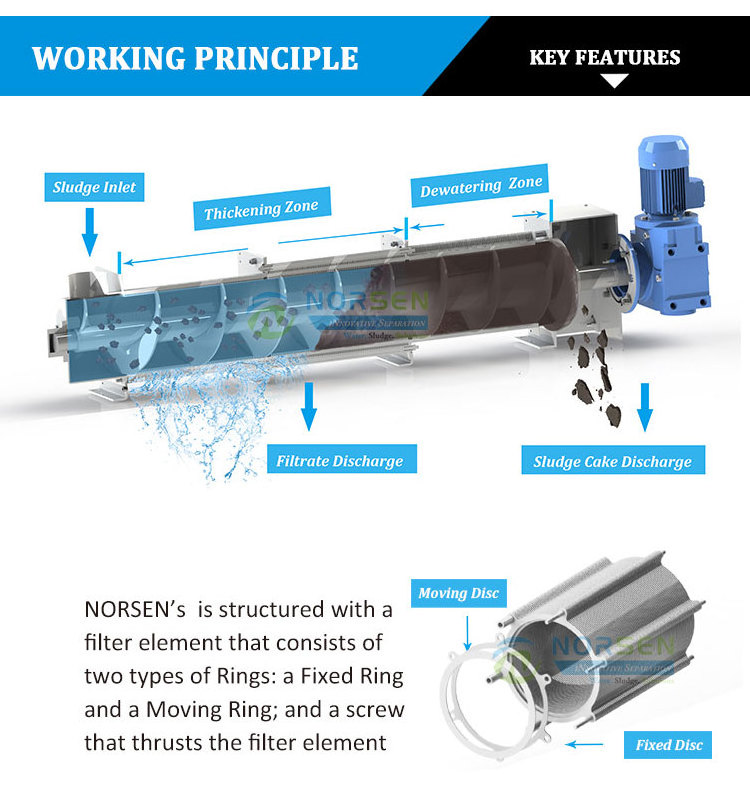

Thickening: When the shaft is driven by the screw, moving rings around the shaft move up and down relatively. Most water is pressed out from the thickening zone and fall down to the filtrate tank for gravity;

Dewatering: The thickened sludge moves forward continuously from the thickening zone towards the dewatering zone. With the pitch of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher. In addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produce;

Self-cleaning: The moving rings rotates continuously up and down under the pushing of the running screw shaft while the gaps between the fixed rings and moving rings are cleaned to prevent from clogging that happens frequently for traditional dewatering equipment.

Dewatering: The thickened sludge moves forward continuously from the thickening zone towards the dewatering zone. With the pitch of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher. In addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produce;

Self-cleaning: The moving rings rotates continuously up and down under the pushing of the running screw shaft while the gaps between the fixed rings and moving rings are cleaned to prevent from clogging that happens frequently for traditional dewatering equipment.

NORSEN’s Control Cabinet/Motor

World famous brand Siemens/Schneider electronic components/They can also be easily distributed in the world

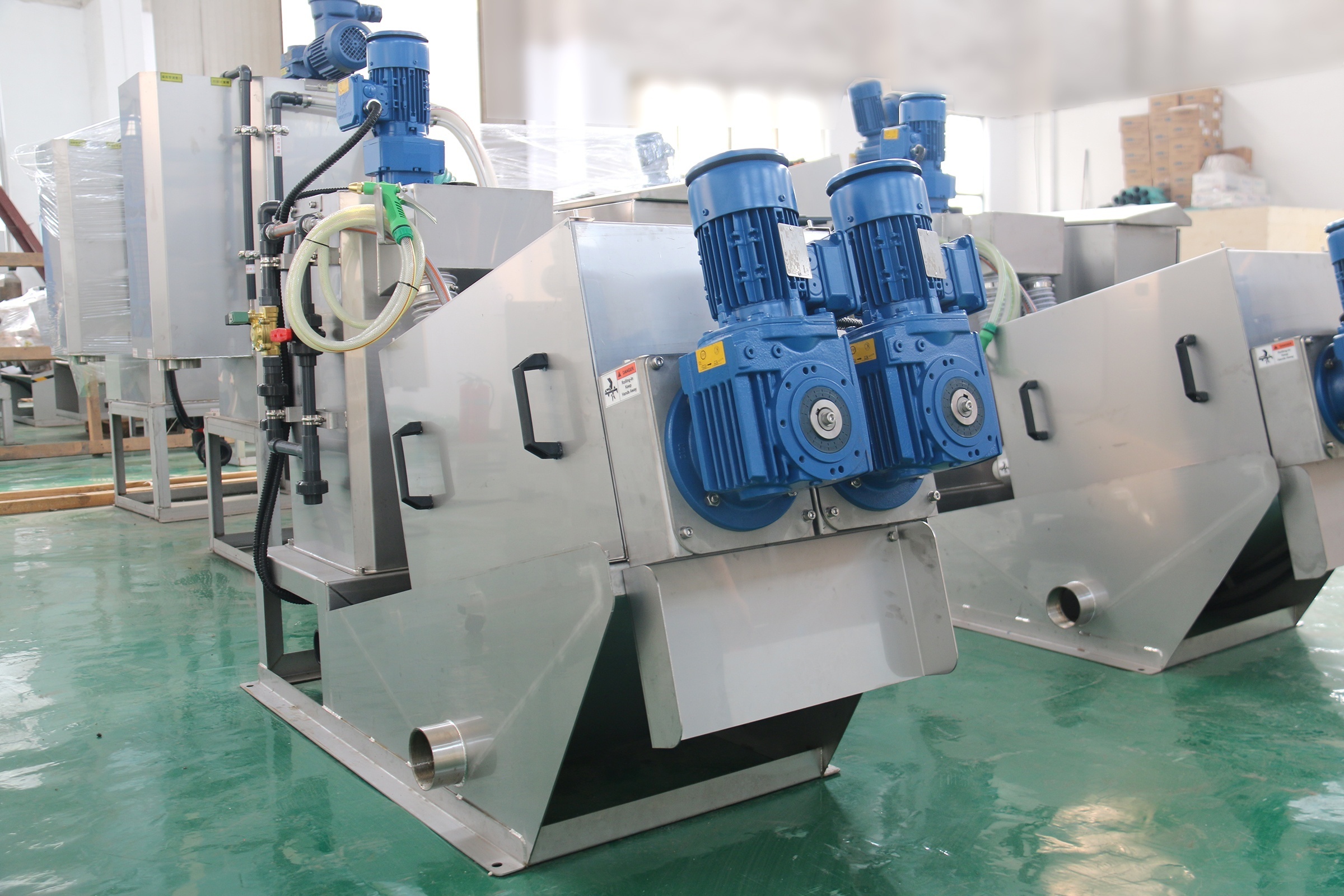

NORSEN’s Machine Details

Here you will see their perfect details

Norsen is equipped with complete production equipment, including German ARKU automatic leveling equipment, ARKU automatic deburring machine, German TRUMPF laser cutting machine, CNC bending machine, shearing machine, welding robot, argon arc welding machine, etc. A complete production system including machining, welding, heat treatment and assembly testing. Greatly improve the precision of the product in the production process.

Norsen hires experienced and skilled welding workers and using welding robot to do straight line welding in order to ensures the welding quality, meantime makes the weld connection on the machine more beautiful and perfect. Due to our factory is located in the environmental industry center of China, Yixing City, here there are lots of experienced workers who have already served in sewage treatment equipment manufacturing over 10 years. One of our welding workers’ working time is over 12 years in sewage equipment fabric. Quality always comes first.

On Multi-Disc Screw press manufacturing, Norsen adopts thermal spraying and surfacing process on screw shaft. Thermal spraying process we also choose the best supplier and it’s Japanese technical process. The spraying harness on the shaft is even and persistent. The harness of screw shaft after spraying compared with other normal stainless steel hardness which is 3 times.

On Multi-Disc Screw press manufacturing,

|

Model

|

Specifications

|

Capacity

|

DS Capacity

|

Size

|

Power

|

|

ES-101

|

100mm screw,1 cylinder

|

0.2~1.0m3/hr

|

5kg/hr

|

1883x760x1145mm

|

0.2kW

|

|

ES-131

|

130mm screw,1 cylinder

|

0.4~2.0m3/hr

|

10kg/hr

|

1883x 760x1145mm

|

0.2kW

|

|

ES-132

|

130mm screw,2 cylinders

|

0.8~ *4.0m3/hr

|

20kg/hr

|

1983x910x1145mm

|

0.3kW

|

|

ES-201

|

200mm screw,1 cylinder

|

0.8~4.0m3/hr

|

20kg/hr

|

2440x855x1265mm

|

0.4kW

|

|

ES-202

|

200mm screw,2 cylinders

|

1.6~8.0m3/hr

|

40kg/hr

|

2535x935x1265mm

|

0.8kW

|

|

ES-301

|

300mm screw,1 cylinder

|

2.0~10m3/hr

|

50kg/hr

|

3200x985x1570mm

|

0.8kW

|

|

ES-302

|

300mm screw,2 cylinders

|

4.0~20m³/hr

|

100kg/hr

|

3340x1295x1570mm

|

1.2kW

|

|

ES-303

|

300mm screw,3 cylinders

|

6.0~30m3/hr

|

150kg/hr

|

3500x1580x1570mm

|

1.95kW

|

|

ES-351

|

350mm screw,1 cylinder

|

4.0~20m3/hr

|

100kg/hr

|

3950x1090x2150mm

|

2.25kW

|

|

ES-352

|

350mm screw,2 cylinders

|

8.0~40m3/hr

|

200kg/hr

|

4050x1550x2150mm

|

3.75kW

|

|

ES-353

|

350mm screw,3 cylinders

|

12~60m3/hr

|

300kg/hr

|

4300x2100x2150mm

|

6.0kW

|

|

ES-401

|

400mm screw,1 cylinder

|

7.0~35m3/hr

|

180kg/hr

|

4350x1260x2350mm

|

3.0kW

|

|

ES-402

|

400mm screw,2 cylinders

|

14~70m³/hr

|

360kg/hr

|

4500x1710x2350mm

|

4.5kW

|

|

ES-403

|

400mm screw,3 cylinders

|

21~105m3/hr

|

540kg/hr

|

4900x2340x2350mm

|

6.7kW

|

Hot Searches