- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Longterm

-

Voltage:

-

450v 380v 410V

-

Dimension(L*W*H):

-

4750X1550X2460mm

-

Power (kW):

-

22

-

Weight:

-

4000

-

Name:

-

Electronic and building wire insulation and sheathing line

-

Capacity:

-

120kg/h

-

Core Diameter Before Sheath:

-

DN3-DN20

-

Core Diameter After Sheath:

-

DN5-DN25

-

Max. Traction:

-

500kg

-

Sink Length:

-

12m

-

Equipment Center Height:

-

1000mm

-

Spark machine:

-

1 piece

-

Caliper Gauge:

-

1 set

-

Blow Dry Device:

-

1set

-

Output (kg/h):

-

120 - 150 kg/h

-

Certification:

-

CE

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

25:1

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Longterm

-

Voltage:

-

450v 380v 410V

-

Dimension(L*W*H):

-

4750X1550X2460mm

-

Power (kW):

-

22

-

Weight:

-

4000

-

Name:

-

Electronic and building wire insulation and sheathing line

-

Capacity:

-

120kg/h

-

Core Diameter Before Sheath:

-

DN3-DN20

-

Core Diameter After Sheath:

-

DN5-DN25

-

Max. Traction:

-

500kg

-

Sink Length:

-

12m

-

Equipment Center Height:

-

1000mm

-

Spark machine:

-

1 piece

-

Caliper Gauge:

-

1 set

-

Blow Dry Device:

-

1set

-

Output (kg/h):

-

120 - 150 kg/h

-

Certification:

-

CE

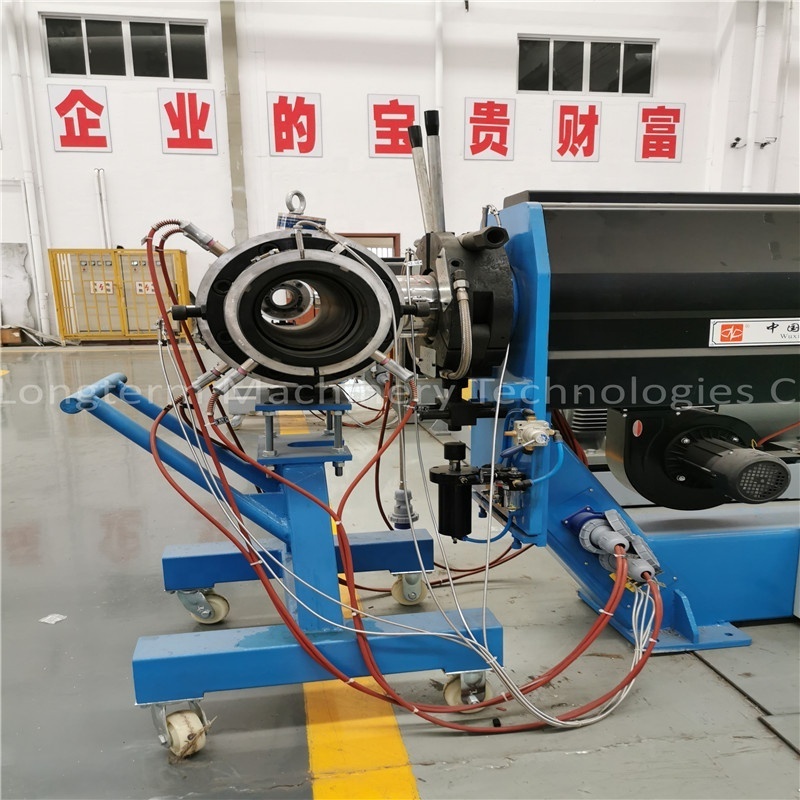

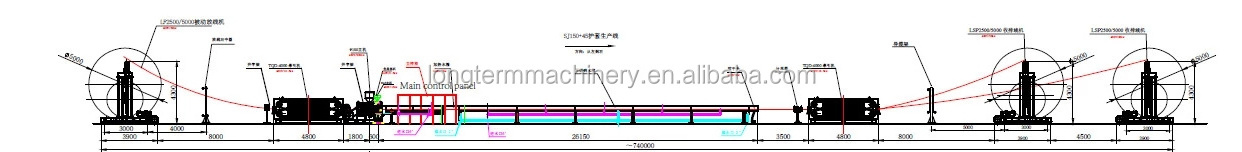

Electronic and building wire insulation and sheathing line / wire and cable extrusion line

Raw material (PP,PE,PA,PET)--------Pay-off --------Caterpillar------ Extruder Head------Water cooling------Drying--------Caterpillar ------Winder/take -up machine

Coaxial Cable Extrusion Line, Medium Low Voltage Cable Conductor Jacket Sheathing Cable Extruder Machine Production Line/is suitable for medium and high voltage single core or multiple core power cable sheath of extruded and double layer extruded at a time. Suitable material for PVC,PE,low smoke zero halogen,conductive PVC,and conductive PE and so on.

This equipment line can be used for cable in the production of inner and outer sheath, at the same time it also can be used for parallel twin wire center tube cable totally medium messager aerial cable extruction production line.

|

Electronic and automotive cable extrusion line, high speed power cable extrision line/ |

|

| Wire Core Diameter | DN3-30mm |

| Out Diamter | DN5-35 |

| Production speed | Max 60m/min |

| Screw350KG/H | 350KG,/H |

| Z4dc Motor ,90kw | 1500 rpm |

| No. of Spinning Yarn Cluster | 2*24 |

| Relase Tension of spinning yarn cluster | 3-30N+-1 |

Production Line Equipment Application :

1,the cable machinery is Suitable for optical cable outer sheath and core strengthening comprehensive production, can also be used for inner protection layer production

2,PE inner sheath,aluminum-plastic compound belt and PE inner sheath.

3,PE outer sheath,aluminum-plastic compound belt,PE composite outer sheath,steel- plastic compound belt,PE composite outer sheath.

4,Parallel double steel wire tube bundling type optic-fibet cable.

Main Features:

1) Compllete and reasonable equiments configuration. The main part adopt from internatonal famous brands, good appearance and easy operatopn.

2) Multi-fuction. With single column double hanging motorized, it is more stable and reliable promance,Especially the DN800 double wire tension controller, it effectively protect core pay-off tension in the progress of instability.

3) Easy operation with LPC system. the machine use PLC programmable controller. the main parameters all will show on screen, at the same time, it has alarm and power off memory fuction.

4) 2*24 aramid twister can use for ADSS optical cables.

Finished Production:

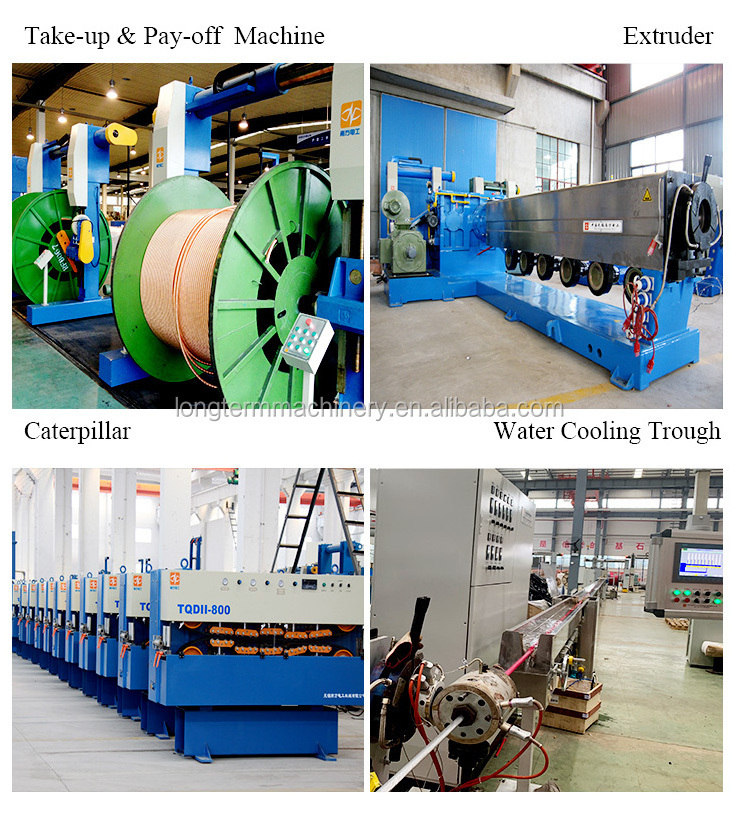

Related Production

1.Take up & Pay off machine for Cable

2.Cable Extruding Machine

Professional ply wooden or iron pakage, or other Standard packaging for shipping sea shipping