- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JY

-

Model Number:

-

JYLDE

-

Name:

-

Sanitary Beer Milk Electromagnetic Flow Meter

-

Diameter Nominal:

-

DN10-DN2000mm

-

Liner material:

-

PTFE,Rubber ,PFA

-

Electrode material:

-

316L ,HC,HB,Ti,Ta

-

Accuracy:

-

0.5%,0.2%

-

Output:

-

4-20mA/Pluse/RS232

-

Connection:

-

Flange,Clamp on ,thread

-

Pressure:

-

1.6Mpa

-

Communication:

-

RS485/Modbus/RS232/HART/Profibus

-

Power supply:

-

220VAC,24VDC,Battery

Quick Details

-

Type:

-

Variable Area Water Flowmeters, Variable Area Petrolum Flowmeters

-

Warranty:

-

24 months

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JY

-

Model Number:

-

JYLDE

-

Name:

-

Sanitary Beer Milk Electromagnetic Flow Meter

-

Diameter Nominal:

-

DN10-DN2000mm

-

Liner material:

-

PTFE,Rubber ,PFA

-

Electrode material:

-

316L ,HC,HB,Ti,Ta

-

Accuracy:

-

0.5%,0.2%

-

Output:

-

4-20mA/Pluse/RS232

-

Connection:

-

Flange,Clamp on ,thread

-

Pressure:

-

1.6Mpa

-

Communication:

-

RS485/Modbus/RS232/HART/Profibus

-

Power supply:

-

220VAC,24VDC,Battery

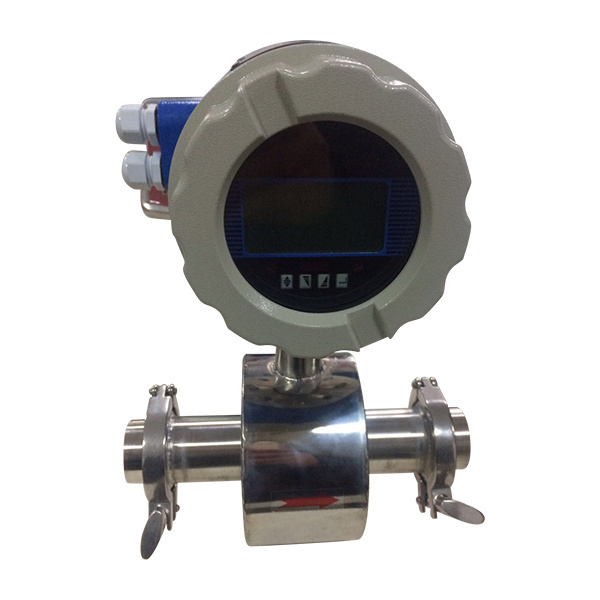

Tri clamp Sanitary Beer Milk Electromagnetic Flow Meter

Product details:

Product Technical Parameter

| Product Name | Tri clamp Sanitary Beer Milk Electromagnetic Flow Meter | Nominal diameter | DN10-DN2000 |

| Medium conductivity | ≥5us/cm | Accuracy | 0.1%,0.5% |

| Flow rate rang | 0.5-10m/s | Communication | RS485(Modbus),HART |

| Medium temperature | ≤100℃ | Load Resistance | 4-20mA is 0-750Ω |

| Ambient temperature |

Sensor:-40℃-+80℃ Converter:-15℃-+50℃ |

Lining material | PTFE,F46,Hard rubber,PFA |

| Pressure Level |

PN1.6MPa or customized |

Electrode material | 316L,Hastelloy B, Hastelloy C,Ti |

| Shell material |

stainless steel, carbon steel |

Installation form | Compact type ,Remoted type |

| Output signal |

4-20Ma,Pluse |

Power consumption | ≤15W |

| Power supply |

220V,24V,Battery |

Protection level | IP65,IP68(need customized) |

| Explosion-proof grade |

Ex II BT6 Gb |

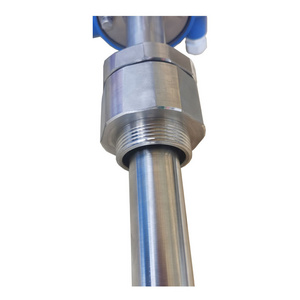

Electrical interface | M20X1.5 |

| Display |

Instantaneous flow, flow rate, percentage, air-to-tube ratio, positive, reverse accumulation, alarm display |

||

How to select lining

| Lining material | The main performance | The scope of application |

| PTFE | 1.1.The most stable chemical properties of plastics in a material that is resistant to boiling hydrochloric acid,sulfuric acid and aqua regia,but also resistant to concentrated acids and various organic solvents, intolerance chlorine trifluoride, liquid oxygen, high velocity liquid oxygen, ozone corrosion.2.Poor wear resistance | Concentrated acid,alkali and other corrosive media |

| PFA | Corrosion resistance with PTEF,strong anti-negative pressure | Can be used for negative pressure state |

| F46 | 1.Corrosion resistance with PTEF.2Can withstand low wear and tear.3,Strong anti-negative pressure. | With PTFE 2.Can be used for low abrasive media |

| Neoprene | 1.Have excellent flexibility,a high degree of tensile force,good wear resistance.2.Resistant to the general low concentrated acid, alkali,salt medium corrosion, corrosion resistant to oxidizing media. | Water, sewage, weakly abrasive mud, pulp |

| Polyurethane | 1.Has excellent wear resistance (equivalent to 10 times the natural rubber).2 acid, alkali performance is poor.3Do not use water mixed with organic solvents. | Strong neutral wear pulp, coal slurry, mud and so on |

Flow Range

| Diameter(mm) | Flow Range(m3/h) | Diameter(mm) | Flow Range(m3/h) |

| 15 | 0.0064-9.5426 | 65 | 0.1195-179.1886 |

| 20 | 0.0113-16.9646 | 80 | 0.1810-271.4336 |

| 25 | 0.0177-26.5072 | 100 | 0.2827-424.1150 |

| 40 | 0.0452-67.8584 | 150 | 0.6362-954.2588 |

| 50 | 0.0707-106.0288 | 200 | 1.1310-1696.4600 |

Features:

1.There is no movable part in the pipes ,hence ,nothing resista the flow and to cause pressure loss or jamming.

2.Measurement is free from series of influences e.g medium density,elasticity ,temperature or electrical conductivity.

3. Corrosion resistance and wearability standard among other indexes are met via selecting different materials for lining and electrodes

4 .The products are equipped with high resoluction backlighted LCD display, which is integrated with menus with both language of english and chinese, it is up to the users' needs to modify the measuring range on site.

5.The devices have also been integrated with series of communiction prorocals i.e.RS485. RS232 ,HART and MODBUS.

6.With programmable low frequency rectangular wave excitation,flow stability is promoted on less power loss.

7. Both power off protection and overrang alarming orients for measured calue,besides,it is also possible to change medium flow direction via programming the integrated sensor,which means installation of sensors are not limited to flow direction and messuring is operatable with both the flow directions.

1. Packing :The flow meter is packed in a shockproof bag and placed in a wooden box In order to ensure the safety of cargo transportation.

2.Delievery:Transportation supports sea, air, railway.Logistics.

3.Payment:T/T,Western Union, Credit card,E-checking,letter of credit ,Cash.

Electromagnetic flowmeter is used to measure the volumetric flow of conductive liquid and slurry in closed pipelines. It is suitable for chemical, electric power, metallurgy, petroleum, water supply and drainage, papermaking, medicine, food and other departments.