- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

2500 ml

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

tepai

-

Year:

-

2023

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

2700*2200*2000

-

Hollow part volume:

-

2.5l

-

Clamping Force (kN):

-

440-1360

-

Power (kW):

-

160-165

-

Weight (KG):

-

35000 KG

-

product name:

-

Bottle Blow Making Machine

-

Function:

-

make pet bottles

-

Machine type:

-

Blow Machine

-

Use:

-

Water Bottle Making

-

Capacity:

-

600 ~2000 Pcs/hour

-

Material:

-

rolled steel

-

Suitable bottle:

-

Water Bottle

-

After-sales Service Provided:

-

3 years

-

Automatic:

-

full automatic

-

Customer's requipment:

-

Customized Designed

Quick Details

-

Neck Diameter(mm):

-

105 mm

-

Max.Bottle Diameter(mm):

-

120 mm

-

Max.Bottle Height(mm):

-

320 mm

-

Bottle Volume(ml):

-

2500 ml

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

tepai

-

Year:

-

2023

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

2700*2200*2000

-

Hollow part volume:

-

2.5l

-

Clamping Force (kN):

-

440-1360

-

Power (kW):

-

160-165

-

Weight (KG):

-

35000 KG

-

product name:

-

Bottle Blow Making Machine

-

Function:

-

make pet bottles

-

Machine type:

-

Blow Machine

-

Use:

-

Water Bottle Making

-

Capacity:

-

600 ~2000 Pcs/hour

-

Material:

-

rolled steel

-

Suitable bottle:

-

Water Bottle

-

After-sales Service Provided:

-

3 years

-

Automatic:

-

full automatic

-

Customer's requipment:

-

Customized Designed

Products Description

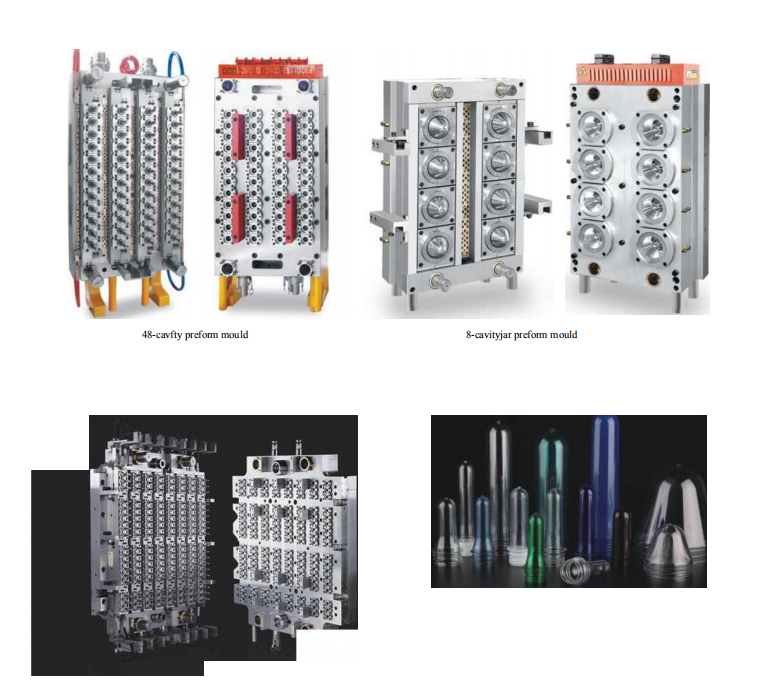

TEPAI water bottle series automatic blow moulding machine

Machine feature:

1. Full-automatic fast and efficient preform feeding System adopts the variable frequency motor star wheel to load preform and save air source.

2. Energy-saving and high efficiency smi open style heating system can save more than 30% energy comparing with counterparts.

3. Double crank arm mould clamping, linkage structure of die block, coordinating with high pressure compensation mould clamping process, solving the problem of the thick mould joint line of completed bottle.

4. Equipped with UK NORGREN High Pressure Combination Valve with the advantages of big flowing and fast reaction, to improve unit production and save energy also.

5. Standard Fittings Supply System to ensure the equipment run steadily and reduce the maintenance cost.

6. MMI Design, Linear Structure, Simple Operation, Convenient and Fast Changing of Mould.

7. This machine equipped with automatic bottle out system, and can be connected with conveyor (Air Blowing Conveyor) automatically and matching with filling system.

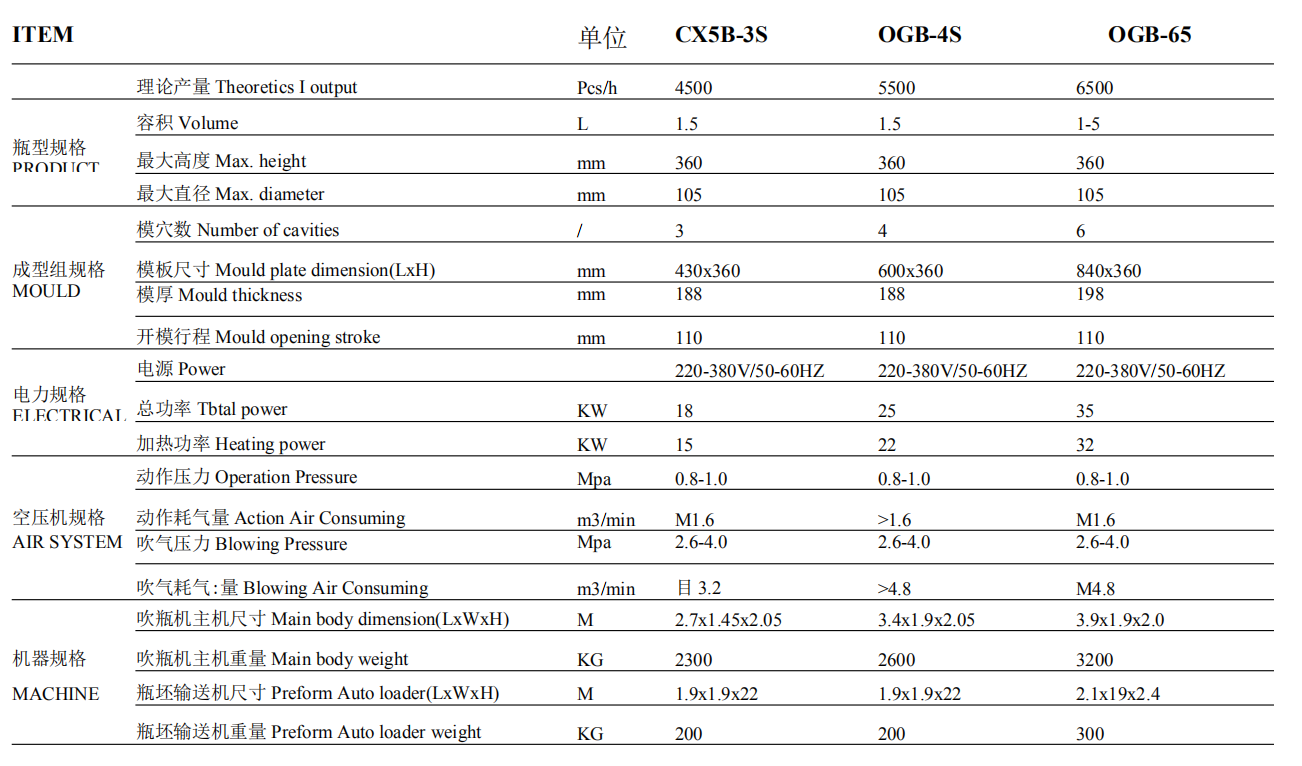

Product Paramenters

Main Parameter

Machine Details

Packaging&shipping

Our customers are all around the world.

Vietnam, Australia, Indonesia, Malaysia, Thailand, Sri Lanka, Kazakhstan, Russia, UAE, Saudi Arabia, Malta, Romania, Italy, India,

Syria, Ethiopia, Egypt, Sudan, Tunisia, Algeria, Kenya, Nigeria, South Africa, Zimbabwe, Mexico, Guatemala, Ecuador, Colombia,

Colombia, ,

Venezuela, Peru....

We have our own service team in

Saudi Arabia, Colombia, Panama, South Africa ...

Hot Searches