- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FULL WERK

-

Place of Origin:

-

Zhejiang, China

-

Car Make:

-

Auto part, machine, transmission

-

Type:

-

Driveshaft

-

Surface finish:

-

Heat treatment & rust prevention

-

Certificate:

-

TS 16949

-

Hardness:

-

45-55HRC

-

Technics:

-

Forging,casting

-

Application:

-

Electronic Accessories

-

Export Markets:

-

America,Europe,Oceania,Mid East,Eastern Asia

-

Color:

-

as picture or customized

-

Product sample:

-

available

Quick Details

-

OE NO.:

-

3-2-479

-

Model Number:

-

3464110011

-

Warranty:

-

1 Years

-

Brand Name:

-

FULL WERK

-

Place of Origin:

-

Zhejiang, China

-

Car Make:

-

Auto part, machine, transmission

-

Type:

-

Driveshaft

-

Surface finish:

-

Heat treatment & rust prevention

-

Certificate:

-

TS 16949

-

Hardness:

-

45-55HRC

-

Technics:

-

Forging,casting

-

Application:

-

Electronic Accessories

-

Export Markets:

-

America,Europe,Oceania,Mid East,Eastern Asia

-

Color:

-

as picture or customized

-

Product sample:

-

available

Cardan Drive Shaft Flange Yoke

Cardan Drive Shaft Flange Yoke. Meet TS/ISO16949 quality certification.High intensity and rigidity ,competitive price, excellent performance and long using life.

| Material: | 1045 steel /C45 or as per customer's requirement |

| Manufacture method: | Forging or casting |

| Surface finish: | Heat treatment & rust prevention |

| LOGO on product & package: | Neutral with no LOGO or as per customer's requirement |

| Package: | PVC bag + Plywood box , or as per customer's requirement. |

OEM are welcome.

Your sample or drawing request are welcome.

Specifications:

Competitive price, through the ISO 9001:2008

Materials: Alloy steel, hot-dip galvanized steel

Made by water glass casting

Fine CNC machining

Many surface treatments are available

Other casting processes: sand casting, die casting, lost-foam casting and permanent mold casting

Materials range: cast iron, ductile cast iron, carbon steel, steel alloy, stainless steel, brass, aluminum and zinc alloy

Weight: 0.03 to 1000kg

Design and production as per customer's requirement

We can make assembly products for you

Short delivery lead time for both samples and orders

Investment casting process describing:

We offers to its customers two types of investment cast processes

They are the shell process and the water glass process

The shell process is used to cast complex high quality parts with requirements of a very good surface finish and close dimensional tolerances

The water glass process is typical of the process in the early stages of investment castings

It generally capable of much larger castings than the shell process, but does not have as good of surface finish or tolerances

Water glass process provides parts that have better surface finish and dimensional tolerances than sand castings

A wide range of alloys is available for both processes

They includes carbon steels, low alloy steels, stainless steels, tool steels and copper based alloys

Other material may be available upon request

Shell investment cast parts can range from a weight of just a few ounces to approximately 50 pounds

If you are concerned with precision in very small parts, we are especially proficient at very fine detail work including teeth and serrations

Water glass castings may range in weight from several ounces to approximately 175 pounds

First article layouts and spectrometer material certifications are provided with all first article samples

A variety of secondary operations can be performed on both types of investment castings

They includes heat treatment, machining, plating, painting, polishing and buffing, assembly services and even custom packaging

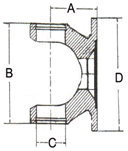

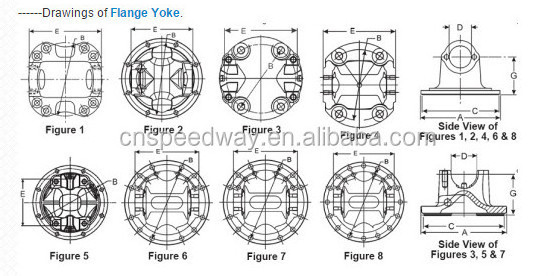

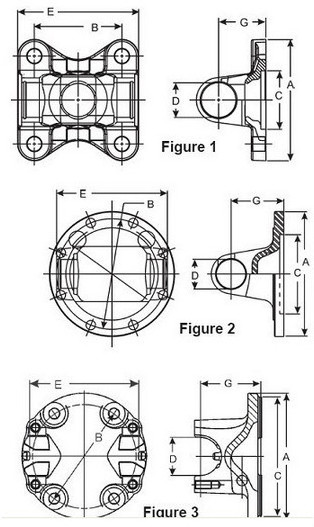

Drawing of Flange Yoke (Driveshaft)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ZDC No. | A | B | C | D | Spicer No.: | Similar | U-joint | Vehicle | Series |

| 864-01 | 72 | 132 | Φ45 | Φ150 | 02-334 | AT1352 | 5-12100X 127.75*45.05 | Mercedes Benz 1519/2219/2220 | 1680 GW2A GW5ALT |

| 864-02 | 62.8 | 98 | Φ38 | Φ130 | 3-2-1139 | AT1350 | 5-12213X 62.1*38.05 | Mercedes Benz 1113 a 2213 | 1510 |

| 864-03 | 85.7 | 191.8 | Φ49.23 | Φ203 | 6.5-2-329 | AT1057 | 5-281X | Scania R-T112 Volvo N-NL10-12 | 1810 |

| 864-08 | 58 | 130 | Φ45.05 | Φ120 | 02-251 | AT1349 | 5-12213XS | M.Benz OM321,1111 | 1510 |

| 864-20 | 41.15 | 98.4 | Φ30.5 | Φ133.3 | 3-2-1579 | Ford,Cobra Mustang 8.8 | 1350 | ||

| 864-29 | 3-2-1719 | Ford Pickup F450 | |||||||

| 864-30 | 3-2-1709 | Ford F150/250/350 | |||||||

| 864-31 | 3-2-159 | Ford C64,D64 VW 6-80 D-700 | 1410 | ||||||

| 864-32 | 3-2-1159 | Valtra BM100 AGCO | 1410 | ||||||

| 864-33 | 3-2-119 |

FORD 2004-2006 GTO rear

2004-2007 CTS-V Front G8 all Front and Rear 2010-2011 Camaro Front and Rear |

1350 | ||||||

| 864-34 | 4-2-669 | Komatsu | 1550 |

Packing detail:

each product will be packed in individual box with label of all information on it, and boxes will be packed in carton, cartons will be packed in wooden cases. Heavy parts, light parts and fragile parts will be packed separately

Delivery Detail:

30-35 days for sea order based on containers.