Beer refrigeration system is mainly used for cooling the saccharifying wort and fermentation, it plays an important role in the

whole process of brewing beer.Our factory refrigerating machine is home famous brand with stable performance, excellent

refrigerating effect, low accident rate. Optimum allocation of refrigerating system can greatly reduce the wastage of the energy,

ensure the stable operation of the beer brewed.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Adjustable

-

Dimension(L*W*H):

-

Customer's Requests

-

Weight:

-

200 KG

-

Product Name:

-

500L Ice water tank for cooling

-

Capacity:

-

200L-20T

-

Material:

-

SUS 304

-

Function:

-

Cooling Liquid

-

Insulation:

-

Polyurethane

-

Thickness:

-

Inner 3mm External 2mm

-

Keywords:

-

beer brewing

-

Color:

-

Customized

-

Surface:

-

Oil mill drawing board

-

Insulation thickness:

-

100mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tonsen

-

Voltage:

-

220/380V

-

Power:

-

Adjustable

-

Dimension(L*W*H):

-

Customer's Requests

-

Weight:

-

200 KG

-

Product Name:

-

500L Ice water tank for cooling

-

Capacity:

-

200L-20T

-

Material:

-

SUS 304

-

Function:

-

Cooling Liquid

-

Insulation:

-

Polyurethane

-

Thickness:

-

Inner 3mm External 2mm

-

Keywords:

-

beer brewing

-

Color:

-

Customized

-

Surface:

-

Oil mill drawing board

-

Insulation thickness:

-

100mm

Product Description

Ice water tank enclosed stainless steel tanks for brewery machine

SHANDONG TONSEN EQUIPMENT CO.LTD

|

Cooling system

|

Chilled water tank

|

SUS304

|

Insulation material: polyurethane, insulation layer thickness 100mm; Inner liner thickness: 3mm, outer package thickness: 2mm, Oil polished wire drawing board on outer surface, sanding belt at weld

|

|

|

Refrigerator machine

|

/

|

20p, assembly

|

|

|

Chilled water pump

|

SUS304

|

Flow 5m3/h, head 25m; Self-priming

|

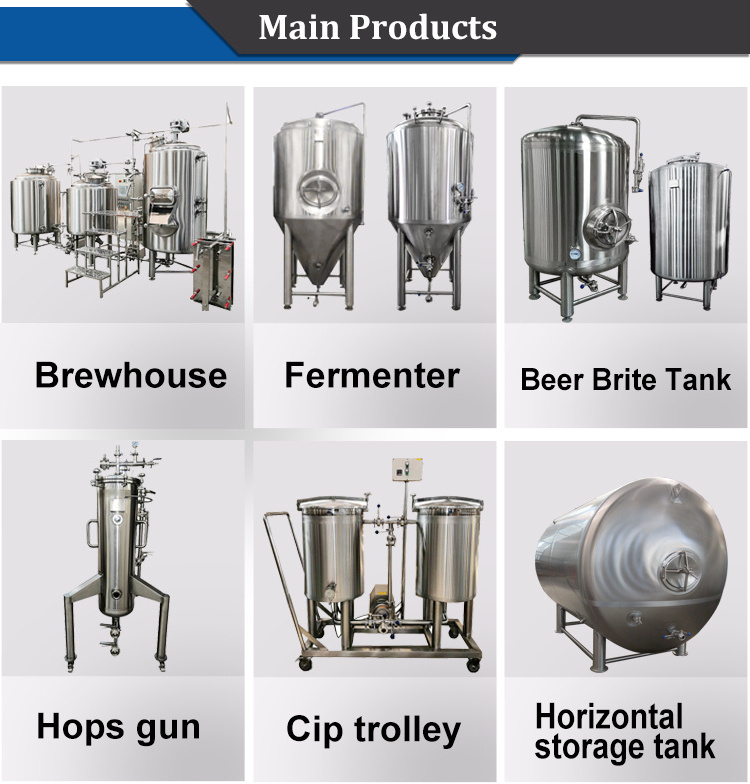

Product Catalog

Related Products

Brewhouse

Beer brewing equipment: Brewhouse

Mash tun, Lauter tun, Boiling tun, Whirlpool tun

Two vessels, three vessels, four vessels brewhouse

Mash tun, Lauter tun, Boiling tun, Whirlpool tun

Two vessels, three vessels, four vessels brewhouse

Fermentation tank

Beer brewing equipment: fermentation tank/fermenters

100 500 1000 1500 2000 3000 liters fermenter and so on

glycol water tank

Including, ice water tank, refrigerator, circulation pump, link pipeline, control system, solenoid valve, etc. The advantages are

short wine making time and fast cooling

short wine making time and fast cooling

chiller

Including: compressor, microcomputer display and so on. The advantages are simple structure, low failure rate, low energy consumption and small footprint

Packing & Delivery

Our Service

a.) Free consultation service before, during, and after sales;

b.) Project planning and design services;

c.) Free debugging instruction of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named port or station by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques;

g.) Provide 36 months complete warrantee for main parts and life-time maintenance service;The seller is responsible for the nature

damage of the machinery in the warranty period except for man-made damage. All spare parts and wearing parts are attached with the

machinery for free;

b.) Project planning and design services;

c.) Free debugging instruction of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named port or station by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques;

g.) Provide 36 months complete warrantee for main parts and life-time maintenance service;The seller is responsible for the nature

damage of the machinery in the warranty period except for man-made damage. All spare parts and wearing parts are attached with the

machinery for free;

Our Company

Our company is a

professional beer equipment manufacturer

. We are specialized in professional design,manufacture,installation and

commissioning of various beer equipments and supporting facilities.

We pay a lot attention to details and we have excellent after sales service.

We can supply all equipments for beer.

commissioning of various beer equipments and supporting facilities.

We pay a lot attention to details and we have excellent after sales service.

We can supply all equipments for beer.

Achievement

With years experience, we have export our equipment to over 20 countries, such as USA, UK, Germany, France, Mexico, Italy, India,

and so on.

Our enginners could help equipment installation, adjusting and worker training overseas.

and so on.

Our enginners could help equipment installation, adjusting and worker training overseas.

FAQ

1.Q:Are you a manufacturer?

A: Yes,we have been in providing the professional products in this field for 15 years.

2.Ask:how to install the machine ?

Answer:we can intrust the install the machine by vedio, email ,picture.....if large project , we can arrange the worker help you

to install it in your country .

3.Q :How you pack the products ?

A: Normally as the export standard packaging or as you required.

4.Q: What is your available port of shipment?

A:Qingdao port,shanghai etc.

5.Q: Is customized available ?

A: Yes, according to your detailed drawings you provide

6.Q:Ask:how to install the machine ?

Answer:we can intrust the install the machine by vedio, email ,picture.....if large project , we can arrange the worker help you

to install it in your country .

7.Q:After Sale Service

1. Warranty policy three years from shipment

2. We will send you the replacement after received the broken part

8.Q: Are you trading company or manufacturer ?

A: We are factory and welcome to visit us at any time.

9.Q: How long is your delivery time?

A: Generally single tanks need 20-30 days, for whole plant need 40-50days.

10.Q: Do you have CE and UL certification?

A: Yes.

11.Q: What is your terms of payment ?

A: 50% deposit and 50% before delivery.

A: Yes,we have been in providing the professional products in this field for 15 years.

2.Ask:how to install the machine ?

Answer:we can intrust the install the machine by vedio, email ,picture.....if large project , we can arrange the worker help you

to install it in your country .

3.Q :How you pack the products ?

A: Normally as the export standard packaging or as you required.

4.Q: What is your available port of shipment?

A:Qingdao port,shanghai etc.

5.Q: Is customized available ?

A: Yes, according to your detailed drawings you provide

6.Q:Ask:how to install the machine ?

Answer:we can intrust the install the machine by vedio, email ,picture.....if large project , we can arrange the worker help you

to install it in your country .

7.Q:After Sale Service

1. Warranty policy three years from shipment

2. We will send you the replacement after received the broken part

8.Q: Are you trading company or manufacturer ?

A: We are factory and welcome to visit us at any time.

9.Q: How long is your delivery time?

A: Generally single tanks need 20-30 days, for whole plant need 40-50days.

10.Q: Do you have CE and UL certification?

A: Yes.

11.Q: What is your terms of payment ?

A: 50% deposit and 50% before delivery.

Contact us

Hot Searches