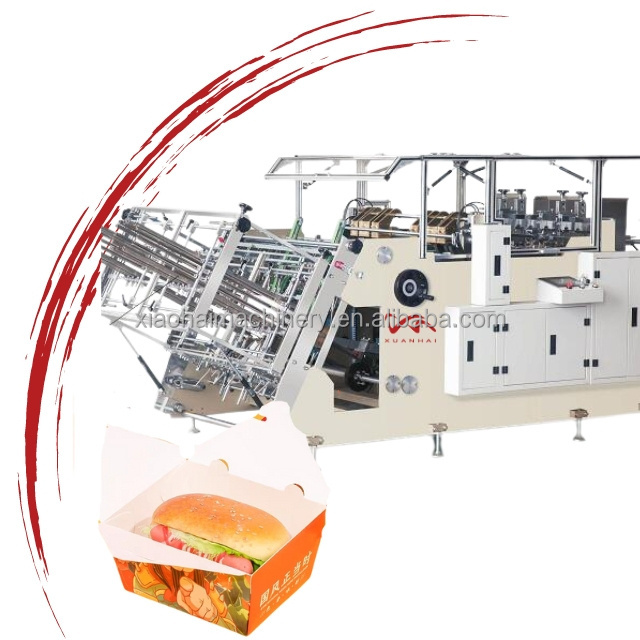

Fully automatic feeding system

high accuracy save labor

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

XUANHAI

-

Voltage:

-

380V

-

Power:

-

5kw/h

-

Dimension(L*W*H):

-

3.48m*1.32m*1.5m

-

Weight:

-

3000 kg

-

Marketing Type:

-

New Product 2023

-

Paper Length:

-

100-450mm

-

Paper Width:

-

100-550mm

-

Box standard size:

-

50*50--320*320mm

-

Edge banding height(H):

-

15-200mm

-

Occupancy of machine:

-

1.2m*4m

-

Bonding/Gluing device:

-

Water-based adhesive

-

Paper thickness:

-

Max 1.5mm

-

Electrical requirement:

-

4kw/h

-

Air requirement:

-

6kg/cm*200L/min

-

Equipment size:

-

3.48m*1.32m*1.5m

Quick Details

-

Production Capacity:

-

180pcs/min

-

Product Type:

-

Paper Box Forming Machine

-

Processing Type:

-

food box

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

XUANHAI

-

Voltage:

-

380V

-

Power:

-

5kw/h

-

Dimension(L*W*H):

-

3.48m*1.32m*1.5m

-

Weight:

-

3000 kg

-

Marketing Type:

-

New Product 2023

-

Paper Length:

-

100-450mm

-

Paper Width:

-

100-550mm

-

Box standard size:

-

50*50--320*320mm

-

Edge banding height(H):

-

15-200mm

-

Occupancy of machine:

-

1.2m*4m

-

Bonding/Gluing device:

-

Water-based adhesive

-

Paper thickness:

-

Max 1.5mm

-

Electrical requirement:

-

4kw/h

-

Air requirement:

-

6kg/cm*200L/min

-

Equipment size:

-

3.48m*1.32m*1.5m

Products Description

Machine Advantages:

* Feature of stereo box die-cutter: high efficiency, reaches 160pcs/min

* Multifunctionality: can manufacture the products such as meal box, chips box, stereo box or burger box with different

specifications on one machine only by changing its molds.

* This machine applies water-based adhesive coating device, attains high efficiency and very high precision. Water-based

adhesive, as water soluble adhesive compostion, is a kind of food-grade glue.

* Most of the machine applies high-quality sealing bearing, prevents from dust or liquid penetrating and impacting the service

life of bearings, with long service life and good stability.

* The whole is driven by high-quality timing belts and ensures almost zero error during its operation.

* Main mould employs pine wood, enjoys high efficiency when replacing its mould.

* Can automatically collect, store and count finished products, and install additionally counter as per the requirements of

customers.

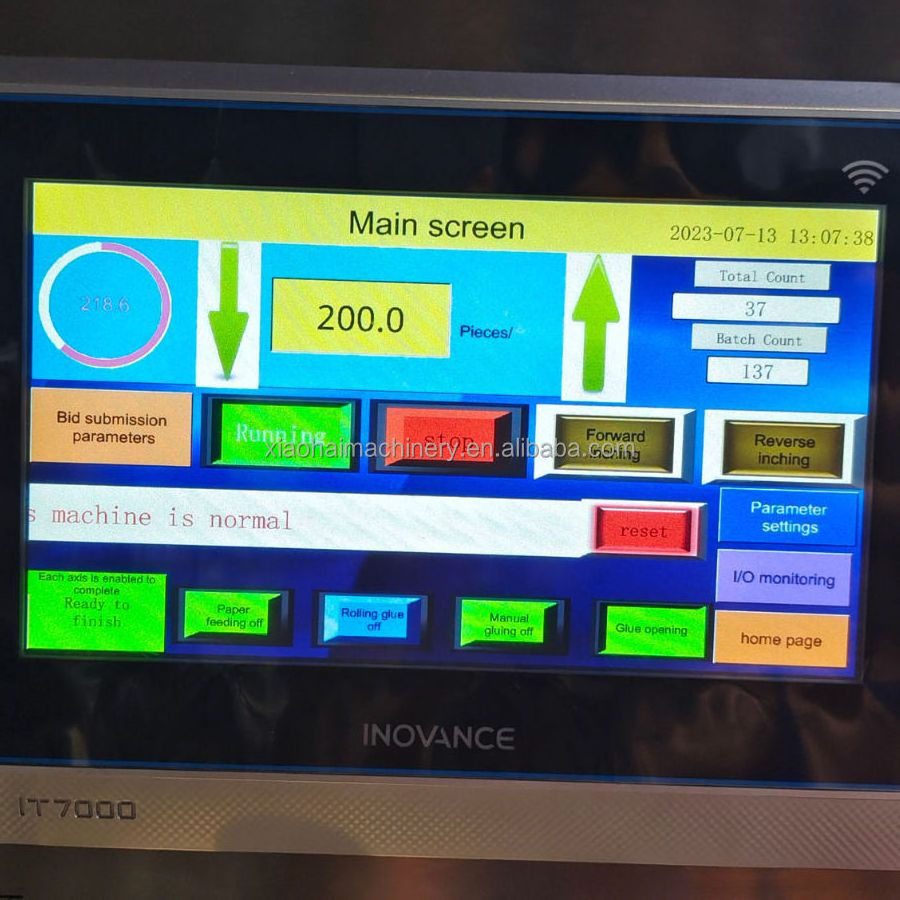

* The machine applies PLC intelligent control system, and automatically stop when there is paper jamming or no paper. It can avoid

unnecessary harm caused by the contact between worker and operation mechanism during the production process.

Standard configuration:

* Integral electric control box ·Feeding unit

* Compressed air device ·Moulding unit

* Water based adhesive coating device ·Servo control unit

* Discharge unit ·A forming die

Opitional :

Hot melt coating system

Air compressor / Dryer

380V power : 15KW

Machine power: 380v

Use thermal bonding system to produce aluminum foil and double PE coated paper boxes, one machine can produce various products

with short replacing time.

* Feature of stereo box die-cutter: high efficiency, reaches 160pcs/min

* Multifunctionality: can manufacture the products such as meal box, chips box, stereo box or burger box with different

specifications on one machine only by changing its molds.

* This machine applies water-based adhesive coating device, attains high efficiency and very high precision. Water-based

adhesive, as water soluble adhesive compostion, is a kind of food-grade glue.

* Most of the machine applies high-quality sealing bearing, prevents from dust or liquid penetrating and impacting the service

life of bearings, with long service life and good stability.

* The whole is driven by high-quality timing belts and ensures almost zero error during its operation.

* Main mould employs pine wood, enjoys high efficiency when replacing its mould.

* Can automatically collect, store and count finished products, and install additionally counter as per the requirements of

customers.

* The machine applies PLC intelligent control system, and automatically stop when there is paper jamming or no paper. It can avoid

unnecessary harm caused by the contact between worker and operation mechanism during the production process.

Standard configuration:

* Integral electric control box ·Feeding unit

* Compressed air device ·Moulding unit

* Water based adhesive coating device ·Servo control unit

* Discharge unit ·A forming die

Opitional :

Hot melt coating system

Air compressor / Dryer

380V power : 15KW

Machine power: 380v

Use thermal bonding system to produce aluminum foil and double PE coated paper boxes, one machine can produce various products

with short replacing time.

ZF800/ZF1200 pizza box making machine can produce hamburger boxes, four-square boxes, pizza boxes, cake boxes, packing boxes, food

boxes (take-away), chip boxes and other cartons made of cardboard and corrugated paper.

boxes (take-away), chip boxes and other cartons made of cardboard and corrugated paper.

Main parameter

|

Model

|

|

ZF800

|

|

|

ZF1200

|

||||

|

Production speed

|

|

60-160pcs/min

|

|

|

80-300pcs/min

|

||||

|

Box standard size

|

|

50*50--320*320mm

|

|

|

50*50--400*400mm

|

||||

|

Paper Box size

|

|

Length : 100-450mm , Angle : 10-40°

Width : 100-550mm , Box Height : 15-200mm |

|

|

Length : 100-450mm , Angle : 10-40°

Width : 100-600mm , Box Height : 15-200mm |

||||

|

Standard Machine Blank Paper size

|

|

Max 320*320mm (if bigger size could custom)

|

|

|

Max 400*400mm (bigger size could custom)

|

||||

|

Paper weight

|

|

200-600 g/m²,card paper,PE coated paper, kraft paper, corrugated paper

|

|

|

200-600 g/m²,card paper,PE coated paper,

kraft paper, corrugated paper

|

||||

|

Paper thickness

|

|

Max 1.5mm corrugated

|

|

|

Max 1.5mm corrugated

|

||||

|

Bonding/Gluing device

|

|

Water-based adhesive

|

|

|

Water-based adhesive

|

||||

|

Electrical requirement

|

|

4kw/h

|

|

|

6.5kw/h

|

||||

|

Air requirement

|

|

6kg/cm²*200L/min

|

|

|

6kg/cm²*200L/min

|

||||

|

Equipment size

|

|

3480*1320*1500mm(L*W*H)

|

|

|

3580*1800*1600mm

|

||||

|

Package measurements

|

|

3500*1320*1500mm(L*W*H)

|

|

|

3600*1800*1600mm (L*W*H)

|

||||

|

G.W.

|

|

2000kg

|

|

|

2500kg

|

||||

※Note: the output quantity metioned above is under normal conditions .Actual output may very on different box shape , quality of

material , and its substance. Roofless box MAX:160pcs/min Square box MAX:150pcs/min Hot Dog&Burger Box MAX:120pcs/min Food box

MAS:100pcs/min

material , and its substance. Roofless box MAX:160pcs/min Square box MAX:150pcs/min Hot Dog&Burger Box MAX:120pcs/min Food box

MAS:100pcs/min

product details

Glue system

Photoelectric system controls.

In case of an error in the carton, the gluing tray will automatically rise, and it will return to normal after one cycle is normal.

In case of an error in the carton, the gluing tray will automatically rise, and it will return to normal after one cycle is normal.

Collecting system

Counting and sorting

after form, the machine

after form, the machine

collect automatically

Automatic gluing system controlled by reduce motor from china. Gluing point is made of sponge and adjusted convenient.

New design driving uses chain instead of belt..The belt is easy to be damaged under the high speed running,and costed much after sold.

More Products

Hot Searches