- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1600*1420*1200mm

-

Power (kW):

-

18.5 kW

-

Weight (KG):

-

1400 KG

-

Name:

-

Tyre Steel Wire Separator Waste Tire Steel Wire Removing Machine

-

Machine Type:

-

Semi Auto

-

Function:

-

Tire debeader machine

-

Raw material:

-

Waste tires

-

Advantage1:

-

Small investment and strong applicability

-

Advantage2:

-

without oil spiliing or off pressure

-

Structure:

-

Frame rotate mechanism,prop mechanism and knife mechanism.

-

Final product:

-

Tire Steel Wire

-

Keyword:

-

High efficiency

-

Marketing Type:

-

Hot Product 2022

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Tianyu

-

Voltage:

-

Customer's Request

-

Dimension(L*W*H):

-

1600*1420*1200mm

-

Power (kW):

-

18.5 kW

-

Weight (KG):

-

1400 KG

-

Name:

-

Tyre Steel Wire Separator Waste Tire Steel Wire Removing Machine

-

Machine Type:

-

Semi Auto

-

Function:

-

Tire debeader machine

-

Raw material:

-

Waste tires

-

Advantage1:

-

Small investment and strong applicability

-

Advantage2:

-

without oil spiliing or off pressure

-

Structure:

-

Frame rotate mechanism,prop mechanism and knife mechanism.

-

Final product:

-

Tire Steel Wire

-

Keyword:

-

High efficiency

-

Marketing Type:

-

Hot Product 2022

Product Overview

Waste tire→cutting diameter of hub→cutting strips→cutting blocks→separate steel wire

Technical Detail

Tire ring cutter machine

Application

This machine is applied to cut tire bead from the whole tire, and this is the first.

This machine is applied to cut tire bead from the whole tire, and this is the first.

Operation

Put tire on the round platform, rotate the wheel to make the four claws catch inside of tire and fix steady, start the power supply, the platform start to rotary,handle the cutting knife control stick leading the knife cut into tire adjust the cutting depth until the tire sidewall cut off.

Put tire on the round platform, rotate the wheel to make the four claws catch inside of tire and fix steady, start the power supply, the platform start to rotary,handle the cutting knife control stick leading the knife cut into tire adjust the cutting depth until the tire sidewall cut off.

Features

|

Model

|

TRC1000

|

|

Capacity

|

1t/h

|

|

Voltage

|

according to coustomer's request

|

|

Max.tire diameter

|

1200mm

|

|

Power

|

3kw

|

|

Weight

|

300kg

|

|

Overall dimensions

|

1650*1050*1500mm

|

The tire ring cutting machine consists of

frame rotate mechanism

,

prop mechanism

and

knife mechanism

.

Tips

:

In order to cut the tire even smoothly and cool the knife,you can use water pump to inject cooling water to the cutting point.

Tire strip cutting machine

Application

The strip cutting machine is applied to cut any tires with diameter

less than 1200mm and large waste rubber into 3-5cm rubber

strips, and this is the second step of tire recycling.

Structure

The machine adopts two disc-shaped blades to cut tire or waste rubber by relative rolling.

The machine adopts two disc-shaped blades to cut tire or waste rubber by relative rolling.

|

Model

|

TSC1000

|

|

Capacity

|

1t/h

|

|

Power

|

5.5kw

|

|

Weight

|

700kg

|

|

Overall dimensions

|

1300*800*1500mm

|

Application

The rubber block cutter is used to cut rubber strips into 3--5cm blocks, and this is the third step of tire recycling.

The rubber block cutter is used to cut rubber strips into 3--5cm blocks, and this is the third step of tire recycling.

|

Model

|

RBC1000

|

|

Capacity

|

1t/h

|

|

Power

|

1.5kw

|

|

Weight

|

650kg

|

|

Overall dimensions

|

1080*850*1250mm

|

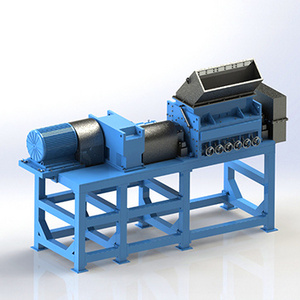

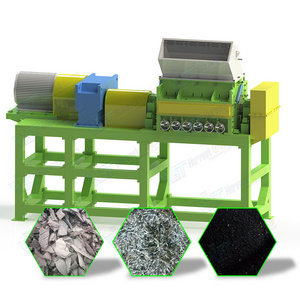

Steel wire extruder

This steel wire extruder is mainly used to separate the rubber and steel wire from the tire bead of all kinds of tires and you can get a complete steel wire ring.

Operation

Start the power, put tire bead into the rollers of the steel wire extruder and then start the button to make the tire bead enter the rollers. After separating the rubber and steel wire, start the button to make the tire bead get out of the rollers, and then take out the tire bead from the rollers, so you get a complete steel wire ring.

|

Model

|

SWE1000

|

|

Capacity

|

100pcs/hour

|

|

Rotation speed of motor

|

1440r/min

|

|

Power

|

18.5kw

|

|

Weight

|

1400kg

|

|

Overall dimensions

|

1600*1420*1200mm

|

Working Site

Product packaging

Hot Searches