- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

1 kN

-

Theoretical Shot Volume(cm³):

-

6.72 cm³

-

Injection Rate (g/s):

-

35 g/s

-

Machine Type:

-

Pneumatic

-

Injection Weight (g):

-

40 g

-

Screw Speed (rpm):

-

1 - 220 rpm

-

Screw diameter (mm):

-

25 mm

-

Weight (KG):

-

55 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

150 mm

-

Model Number:

-

NG-QZ40

-

Brand Name:

-

NEWGOER

-

Power (kW):

-

1 kW

-

Diameter of Plunger Piston:

-

35mm

-

Heating Cavity Size:

-

35 * 110 mm

-

Injection Pressure:

-

1T

-

Temperature Range:

-

RT-450℃(±3℃)

-

Injection Time:

-

0-9999s Settable

-

Cavity Structure:

-

Exchangeable mold cavity

-

Max. Mold Mounting Size:

-

200 * 200 * 210

-

Machine Dimension:

-

600 * 660 * 1400

-

Air Supply:

-

0.6mpa

-

Voltage:

-

220V/ 60HZ

Quick Details

-

Plasticizing Capacity(g/s):

-

35

-

Mold Height(mm):

-

40 - 230 mm

-

Ejector Stroke(mm):

-

25 mm

-

Ejector Force(kN):

-

1 kN

-

Theoretical Shot Volume(cm³):

-

6.72 cm³

-

Injection Rate (g/s):

-

35 g/s

-

Machine Type:

-

Pneumatic

-

Injection Weight (g):

-

40 g

-

Screw Speed (rpm):

-

1 - 220 rpm

-

Screw diameter (mm):

-

25 mm

-

Weight (KG):

-

55 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

150 mm

-

Model Number:

-

NG-QZ40

-

Brand Name:

-

NEWGOER

-

Power (kW):

-

1 kW

-

Diameter of Plunger Piston:

-

35mm

-

Heating Cavity Size:

-

35 * 110 mm

-

Injection Pressure:

-

1T

-

Temperature Range:

-

RT-450℃(±3℃)

-

Injection Time:

-

0-9999s Settable

-

Cavity Structure:

-

Exchangeable mold cavity

-

Max. Mold Mounting Size:

-

200 * 200 * 210

-

Machine Dimension:

-

600 * 660 * 1400

-

Air Supply:

-

0.6mpa

-

Voltage:

-

220V/ 60HZ

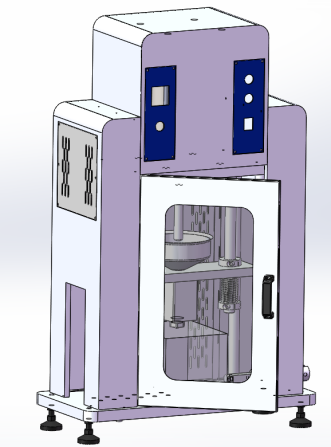

Pneumatic Vertical Injection Molding Machine

>>C l i c k H e r e F o r M o r e I n f o r m a t i o n ! ! !

>>C l i c k H e r e F o r M o r e I n f o r m a t i o n ! ! !

Summary:

Injection Molding Machine is a mechanical equipment. It is usually composed of injection system, closing system, pressure transmission system, electrical control system, lubrication system, heating and cooling system, safety monitoring system and so on.

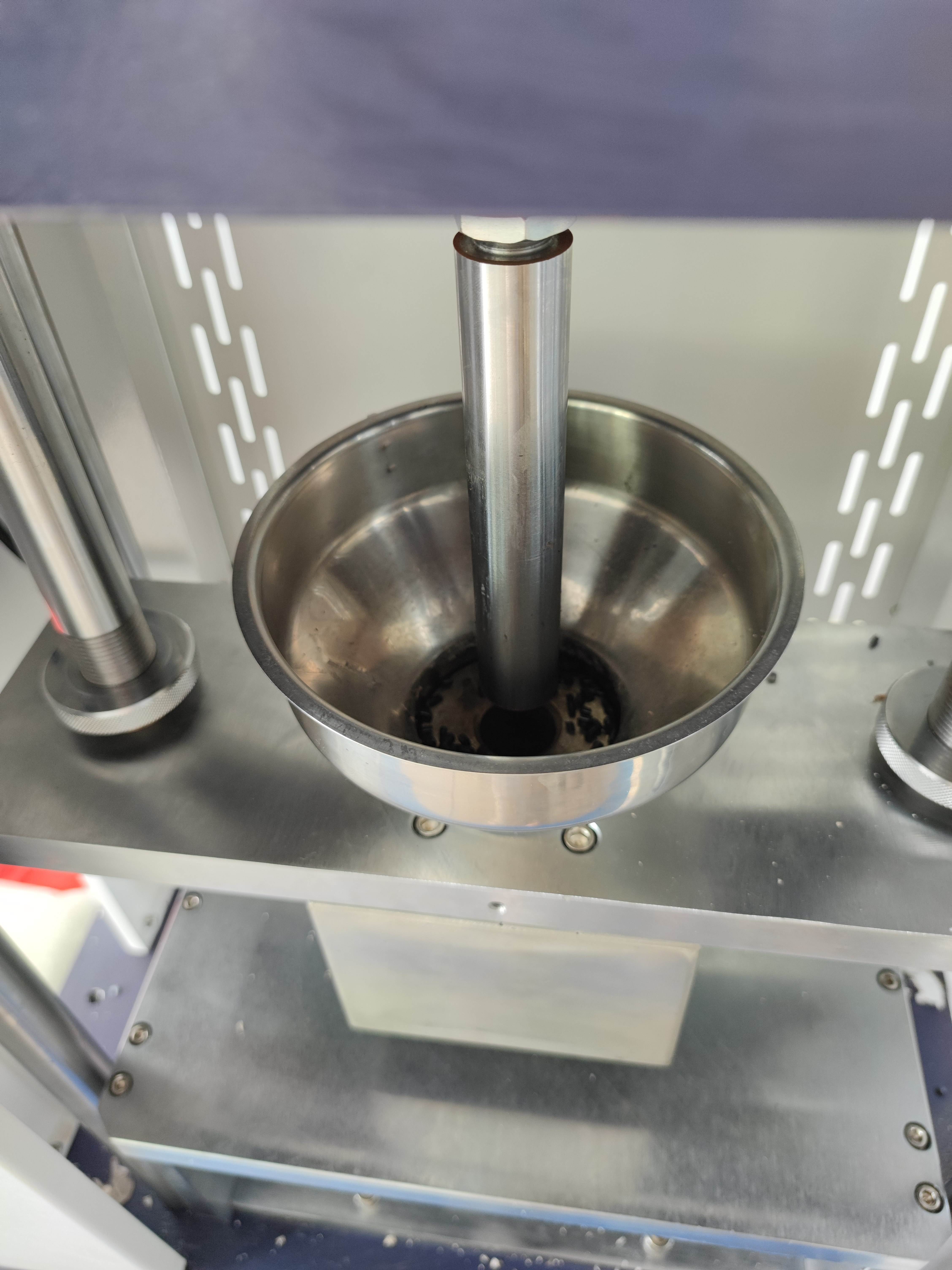

Injection system is one of the most important parts of injection molding machine, generally there are three main forms: plunger type, screw type, screw preplastic plunger injection type. At present the most widely used screw type. Its function is that, in a cycle of the plastic injection machine, a certain amount of plastic can be heated in a specified time after plasticizing, under a certain pressure and speed, the molten plastic is injected into the mold cavity through the screw.

Our NG-QZ Pneumatic Small Injection Molding Machine is small area save space and affordable, is

the good choice of many customers.

Features:

1. Humanized work table height design, suitable for large machine, comfortable operation, so as to reduce the labor intensity of the operator, improve work efficiency.

2. The injection molding machine adopts pneumatic operation design to realize the requirements of fast, simple and easy maintenance.

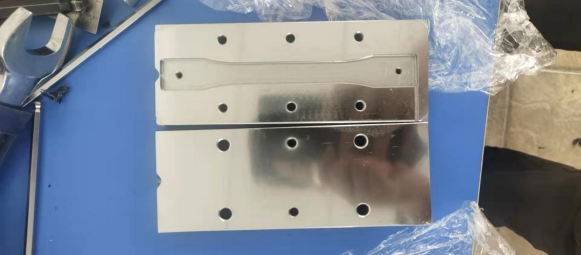

3. The template and the moving parts of the machine column, the use of high rigid copper bushing, to achieve smooth movement and long service life and high precision requirements.

4. Injection molding system adopts pneumatic double guide column design, smooth movement, high injection precision.

5. Feeding using manual feeding.

6. Convenient installation and disassembly of the platform pliers mold, which can greatly improve the output and working efficiency.

7. Mold adjustment separate side control, convenient from the Angle of view, user-friendly Angle convenient to quickly change the mold.

8. User-friendly design of the lifting system, convenient, fast, save time and manpower to adjust the mold or change the mold.

Speficiations:

|

Model |

NG-QZ40 |

NG-QZ60 |

|

Diameter of Plunger Piston |

45mm |

|

|

Heating C avity S ize |

35 * 11 0 mm |

45 * 11 0 mm |

|

Max. Injection Quantity |

40g |

60g |

|

Injection Pressure |

2T |

|

|

Temperature Range |

RT- 45 0℃( ±3℃ ) |

|

|

Control |

Pneumatic |

|

|

Cavity S tructure |

Exchangeable mold cavity, effectively prevent mutual pollution of materials |

|

|

Max. Mold Mounting Size |

200 * 20 0 * 21 0 |

2 1 0 * 20 0 * 21 0 |

|

6 00 * 6 60 * 140 0 |

65 0 * 6 60 * 155 0 |

|

|

Power |

1000W |

1200W |

|

0.6mpa |

||

|

Voltage |

||

|

Remark: Projection Door is optional, please contact us if you needed. |

||

After sales Service

1) 12 months product warranty.Free components will be provided if any performance failure occurs

within 12 months caused by non-human damage.

2) If you face any problems in future during testing process, We will serve as a technical adviser for

lifetime, give you a reply within 48 hours and the solution provided within 3 working days.

3) We will provide some guidance for the normal use of the machine, and in the case of the machine

is not used for a long time,protection guidance provided, then keep the good performance of the

machine.

4) We can offer operation video and operation manual,also can provide video-conference.

5) If necessary, on-site service will be provided, but the transport and travel expense shall be borne

by customer.