- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Rubber Products

-

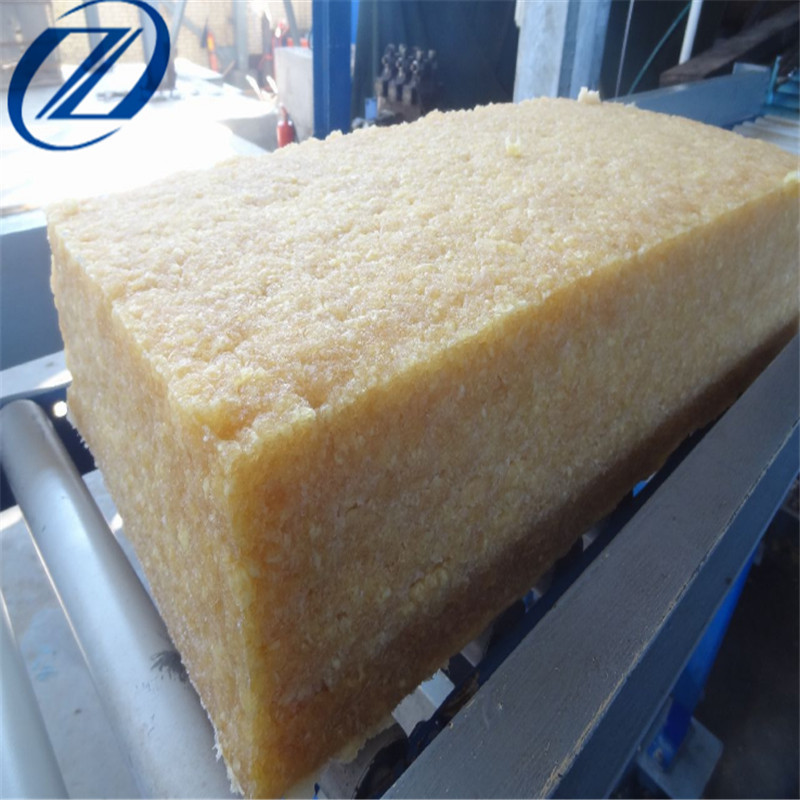

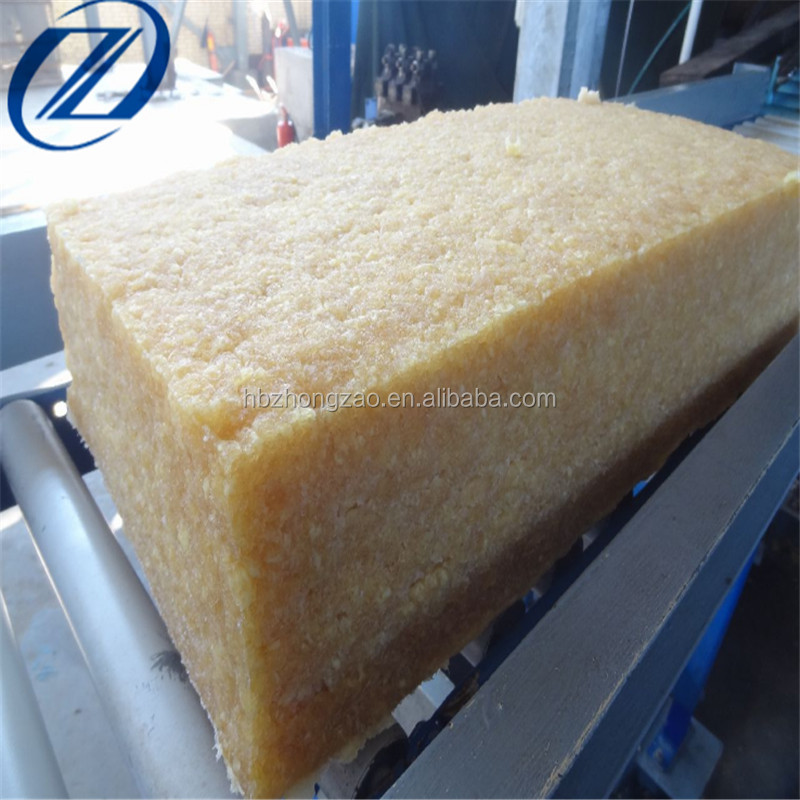

Appearance:

-

Light Yellow Blocky Solid

-

Color:

-

Light Yellow

-

Types of SBR:

-

SBR 1705 1502 1500

-

Name:

-

Sbr Rubber 1502

-

Material:

-

Rubber Material

-

Certification:

-

ISO9001

-

SBR application:

-

Connveyor Belt

-

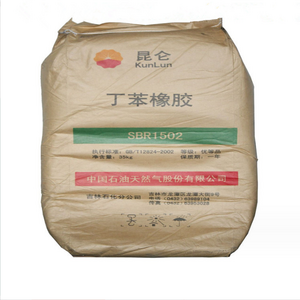

Packing:

-

35kg Kraft Paper Bag

-

SBR:

-

Standard Rubber

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

zhongzao

-

Model Number:

-

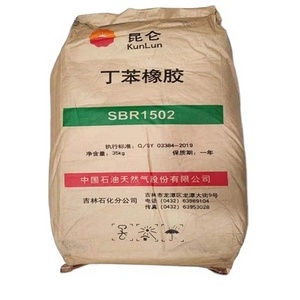

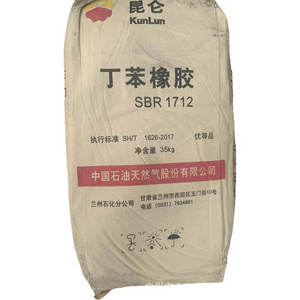

SBR1500,1502,1712,1778

-

Application:

-

Rubber Products

-

Appearance:

-

Light Yellow Blocky Solid

-

Color:

-

Light Yellow

-

Types of SBR:

-

SBR 1705 1502 1500

-

Name:

-

Sbr Rubber 1502

-

Material:

-

Rubber Material

-

Certification:

-

ISO9001

-

SBR application:

-

Connveyor Belt

-

Packing:

-

35kg Kraft Paper Bag

-

SBR:

-

Standard Rubber

Cheap Price Virgin SBR Rubber Sheets supply Top Quality Styrene Butadiene Rubber (SBR 1500,1502,1712,1778)

SBR - 1502 is general not polluting the most typical soft emulsion poly styrene butadiene rubber varieties, and its performance and SBR - 1500, good tensile strength, abrasion resistance and flexible performance. SBR - 1502 is widely used in bright colors and light color rubber products, such as tire lateral, transparent rubber shoes, adhesive tape, medical products and other general color products, etc.

|

|

|||||

|

|

Property |

Test Method |

|||

|

A |

B |

C |

|||

|

Volatile matter % |

≤0.60 |

≤0.75 |

≤0.90 |

GB/T 6737-1997 |

|

|

Ash % |

≤0.50 |

GB/T 4498-1997 A |

|||

|

Organic acid % |

4.50-6.75 |

GB/T 8657-2000 A |

|||

|

Soap % |

≤0.50 |

||||

|

Bound styrene % |

22.5-24.5 |

GB/T 8658-1998 |

|||

|

Mooney viscosity 50ML(1+4)100 |

45-55 |

44-56 |

GB/T 1232.1-2000 |

||

|

Compound 50ML(1+4)100 |

≤93 |

||||

|

300% 145MPa

|

25min |

M±2.0 |

M±2.5 |

|

|

|

35min |

20.6±2.0 |

20.6±2.5 |

|||

|

50min |

21.5±2.0 |

21.5±2.5 |

|||

|

Tensile strength (145,35min), MPa |

≥25.5 |

≥24.5 |

|||

|

Elongation (145,35min),% |

≥340 |

≥330 |

|||

SBR - 1712

is a kind of filling high aromatic hydrocarbon oil varieties of polluting soft emulsion poly styrene butadiene rubber, it has good tackiness, abrasion resistance and machinability, as well as cheap price, etc. SBR - 1712 is widely used in passenger car tire tread rubber, tire tread rubber, conveyer belt, rubber hose and general black rubber products, etc.

|

|

|||||

|

|

Property |

|

|||

|

A |

B |

C |

|||

|

Volatile matter% m/m |

≤0.60 |

≤0.80 |

≤1.00 |

GB/T 6737-1997 |

|

|

Ash% (m/m) |

≤0.50 |

GB/T 4498-1997 |

|||

|

Organic acid %m/m |

3.90-5.70 |

|

|||

|

Soap %m/m |

≤0.50 |

||||

|

Bound styrene% m/m |

22.5-24.5 |

GB/T 8658-1998 |

|||

|

Oil %m/m |

25.3-29.3 |

24.3-30.3 |

SH/T 1718-2002 |

||

|

Mooney viscosity ML(1+4)100 |

44-54 |

43-55 |

42-56 |

GB/T 1232.1-2000 |

|

|

Compound ML(1+4)100 |

≤70 |

GB/T 1232.1-2000 ASTM IRB No.7 |

|||

|

300%Modulus (145),MPa |

25min |

9.8-13.8 |

9.3-14.3 |

GB/T 8656-1998 ASTM IRB No.7

|

|

|

35min |

12.1-16.1 |

11.6-16.6 |

|||

|

50min |

13.0-17.0 |

12.5-17.5 |

|||

|

145,35min), MPa

|

≥19.4 |

≥18.4 |

|||

|

(145,35min), % Elongation |

≥380 |

≥370 |

|||

SBR - 1500

is general polluting soft breast is most varieties of poly (styrene butadiene rubber, raw rubber adhesive property and processing performance are excellent, vulcanized rubber abrasion resistance, tensile strength, tear strength and resistance to aging performance is good. SBR - 1500 is widely used in carbon black as reinforcing agent and low requirements for color products, such as tire tread, tire tread, conveyor belt, rubber hose, mold products and extrusion products, etc.

35kg/bag,, 20-22 tons in 20ft container

1.Q.: Are you a factory or trading company?

A.: We're a factory, we'll provide you the superior quality and best service.

2.Q.: Where is your factory located, how I can visit there?

A.: All our clients, from home or abroad, are warmly welcome to visit us!

3.Q.: What's the material for your product?

A.: best quallity to produce your product

4.Q.: What certificate do you have ?

A.:ISO9001/CE/EN71/ASTMF963

5.Q.:How does your factory control the quality?

A.:Quality is the Priority, we always pay great important to quality from beginning to end, we have professional QC for item quality from spare parts to finished goods.

6.Q.: How many days for mass production?

A.:20 days after all artwork and 30% deposit are confirmed.

7.Q.: How can I get the samples? is the sample free?

A.: 7-10 days to send free samples by DHL, TNT, UPS

8. Q.: What's your MOQ?

A.: as your request ,, we do OEM.

9.:Q Can you do OEM product?

A.: Sure, we accept OEM design, we have made many times before.