Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V or Customized

-

Dimension(L*W*H):

-

30M * 4M * 2.5M

-

Power (kW):

-

155

-

Weight:

-

18000 KG

-

Brand Name:

-

FULLWIN

-

Raw material:

-

PVC/PP/PE

-

Processing Type:

-

Extruding Equipment

-

Usage:

-

Hollow grid sheet

-

Final product:

-

Plastic sheet board

-

After-sales Service Provided:

-

Engineers

-

Inverter:

-

Delta Inverter

-

Motor:

-

AC Motor

-

Color:

-

Customized Color

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

36:1

-

Screw diameter (mm):

-

100

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V or Customized

-

Dimension(L*W*H):

-

30M * 4M * 2.5M

-

Power (kW):

-

155

-

Weight:

-

18000 KG

-

Brand Name:

-

FULLWIN

-

Raw material:

-

PVC/PP/PE

-

Processing Type:

-

Extruding Equipment

-

Usage:

-

Hollow grid sheet

-

Final product:

-

Plastic sheet board

-

After-sales Service Provided:

-

Engineers

-

Inverter:

-

Delta Inverter

-

Motor:

-

AC Motor

-

Color:

-

Customized Color

Main Product

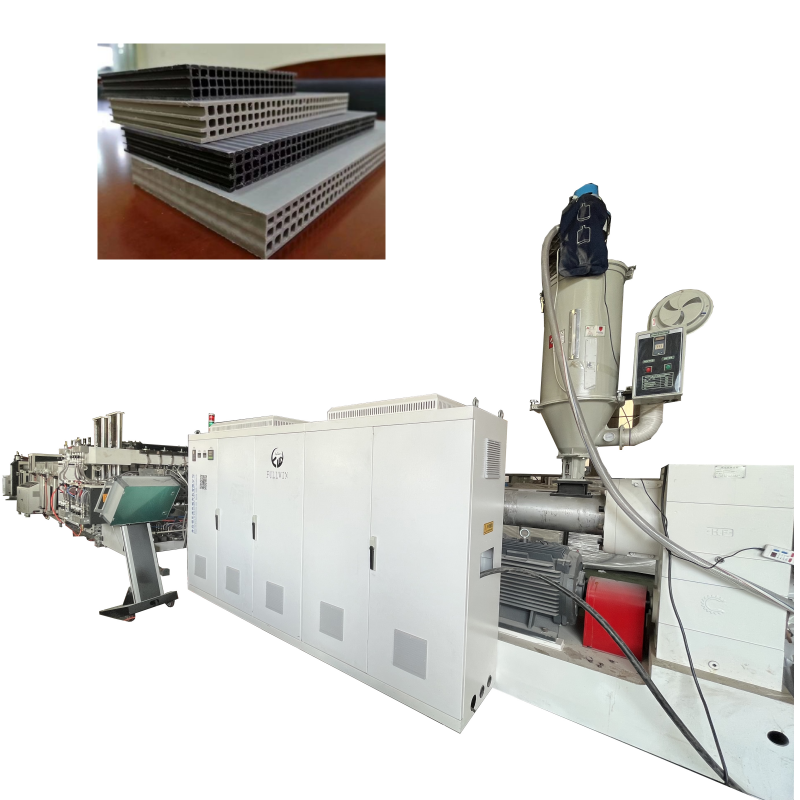

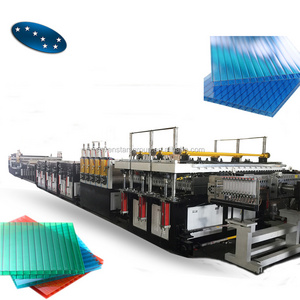

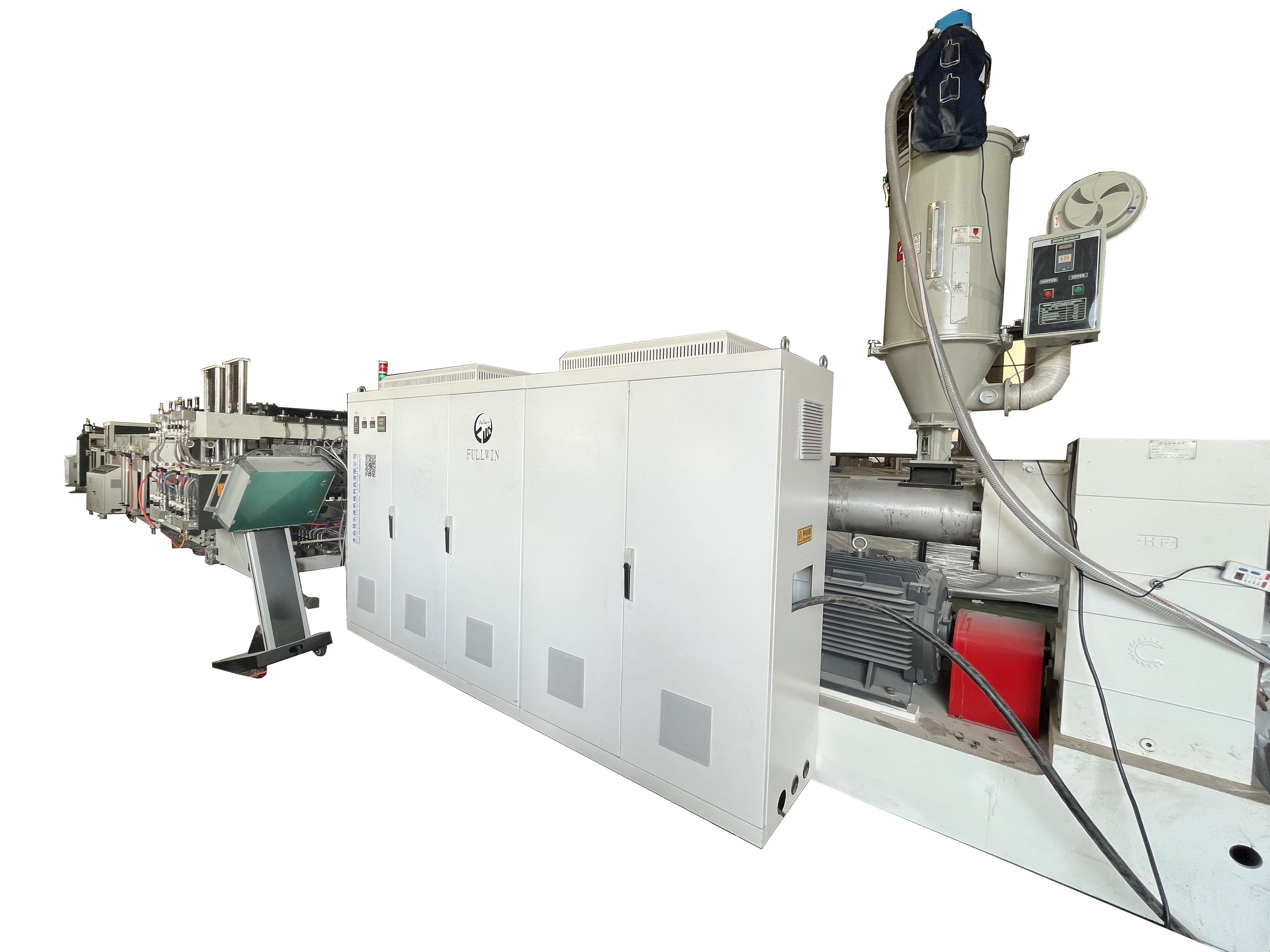

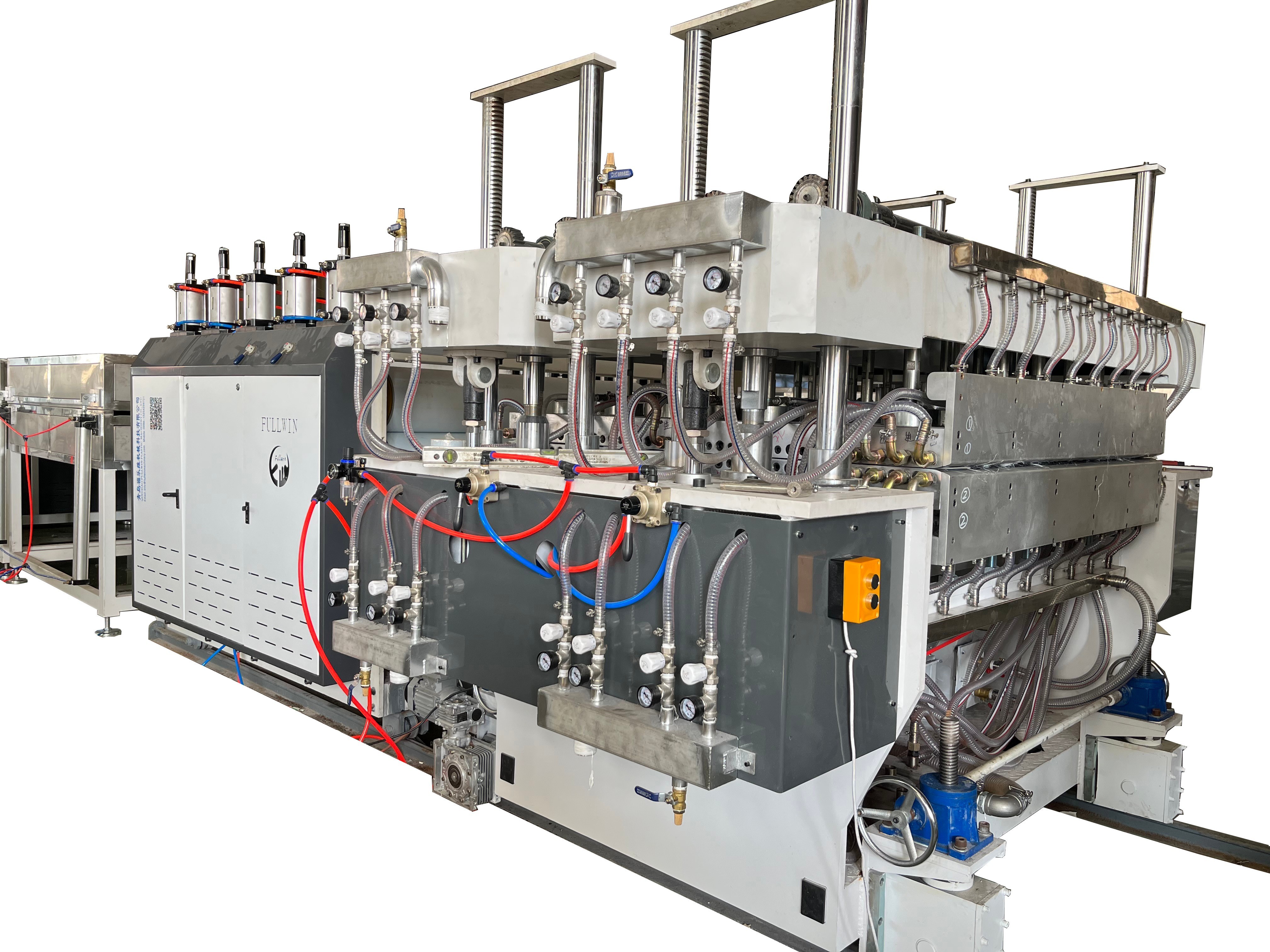

PP PE PC Hollow Board/Sheet/Grid Production Line

Fullwin hollow sheet making machine is independently developed by our company. The sheet thickness is ranging from 1.6 mm to 18 mm, the width of sheets can be customized according to customer requirements from 915 to 2450 mm.

This production line realizes continuous production of PC /PP/PE hollow grid plate,which is applicable to construction decoration, advertisements collocation, and noise insulation of highway as well as packing. PP/PE hollow grid plate is an ideal substitute for paper box in making packing box. It is characterized by light weight, high intensity, damp proof and anti-corrosion capability.

The surface of final products are smooth, clean and beautiful. What is more, we attach importance to the precision so the size error is indeed small. These produced sheets can be nailed and gouged, owing high corrosion resistance capability, strong flame retardant capability and many other advantages.

The whole production line is composed of single screw extruder, hydraulic screen changer, mold, setting machine, primary tractor, annealing furnace, cooling box, secondary tractor, crosscutting machine and conveyor.

|

NO.

|

Description

|

QTY

|

|

1

|

Auto Feeder

|

1 set

|

|

2

|

Single Screw Extruder

|

1 set

|

|

3

|

Screen Changers

|

1 set

|

|

4

|

Die Head and Mould

|

1 set

|

|

5

|

Vacuum Sizing Table

|

1 set

|

|

6

|

Six Roller Hauling Off Machine

|

1 set

|

|

7

|

Preheating Device

|

1 set

|

|

8

|

Cooling Bracket

|

1 set

|

|

9

|

Cutting Device

|

1 set

|

|

10

|

Two Roller Hauling Off Machine

|

1 set

|

|

11

|

Transverse Machine

|

1 set

|

|

12

|

Stacker

|

1 set

|

Details of product

Single Screw Extruder

Fullwin independently developed single screw extruder is of high melt efficiency and continuous production stability. What is more, extraordinary performance gearbox reducer has long life and low noise. Fullwin single screw extruder can be used for PVC PE PP, three material production because its surface nitriding treatment which prolongs the screw using life. All these innovative design are for our clients' better using experience.

Screen Changer

The material of filter plate we used is 38CrMoAl, just for serving on the whole production line for long time. The diameter of the filter will be adjusted to better suitable for our customers' needs. With the help of hydraulic cylinder, this part can be easily operated.

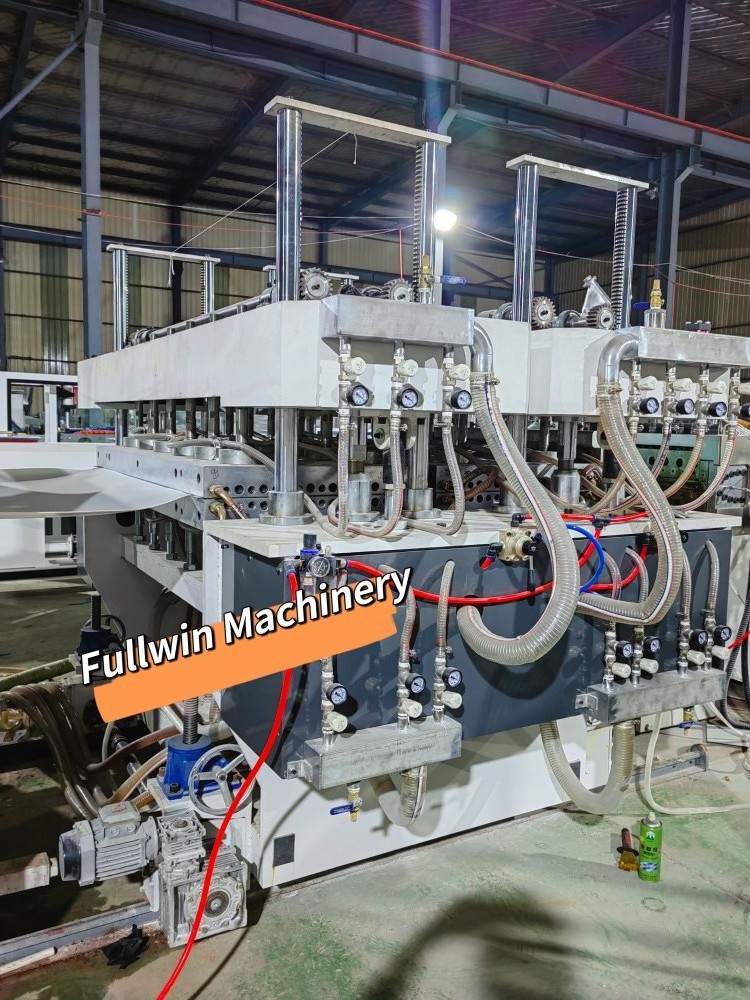

Die Head & Mould

Fullwin high quality die head for hollow sheet production line can be used for producing 915-2450 wide final products, the thickness ranging from 1.6mm to 18mm.

Cr-plated heat resistant steel alloy is applied for T-dies, thus flowing channels are of clothes-hanger type

design. With excellent flow distributing systems, we want to make sure that flows can go evenly to all the whole dies, and with adjusting system equipped onto up and down die lips, we want to make sure that all sheets have good thicknesses.

Vacuum Sizing Table

Vacuum system and forming system are well designed and located, which is equipped with a quick heat exchange die. Forming systems and cooling system is well and precisely located among vacuum systems in good orders. This vacuum systems is composed of 2 independent sub-systems, each of them are equipped with many triangle type close-circuit vacuum tubes. All close circuit systems are equipped with vacuum conditioning and monitoring systems, just for making sure to have a stable and even vacuum degree on all sheet surfaces.

Six Roller Hauling Off Machine

Preheating Device

Cooling Device

Cutting Device

Final Product & Application

About Us

Qingdao Fullwin Machinery Technology Co., Ltd. is a manufacturer specializing in the production of plastic corrugated pipe equipment. We have 3 factories with a total area of more than 10,000 square meters and export 10+ containers every month. Our machines include plastic corrugated pipe production lines, plastic pipe production lines, plastic profile production lines, etc. We are dedicated to providing customers with complete project quotation and one-stop purchasing services. Since establishment, Fullwin keeps market oriented and technology based, committed to researching and

developing sophisticated technology products, which can guide us provide high efficiency and energy-consuming equipment for the plastic products industry.

Fullwin Machine List

* High Speed Single-Wall Corrugated Pipe Extrusion Line

* Double Wall Corrugated Pipe Extrusion Line

* Corrugated Pipe Auxiliary Equipment

* PVC/UPVC/CPVC Pipe Extrusion Line PVC/UPVC/CPVC

* PE/PPR Compound Pipe Extrusion Line PE/PPR

* Spiral Corrugated Pipe Extrusion Line

* PVC Fiber -Reinforced Pipe Extrusion Line PVC

* PVC Suction Hose Extrusion Line PVC

* PVC/WPC Window frame Profile / Door Board Extrusion Line PVC/WPC

* PET/PP Packing Belt Extrusion Line PET/PP

* PP/PE/ABS Plastic Plated Extrusion Line

* PVC Shinning/Semi-Shinning Foam Board Extrusion Line

* PP Hollow Grid Sheet Extrusion Line

* PP/PE Granulating Extrusion Line

*EPE Fruit foam net extrusion machine

*Auxiliary Equipment

* Double Wall Corrugated Pipe Extrusion Line

* Corrugated Pipe Auxiliary Equipment

* PVC/UPVC/CPVC Pipe Extrusion Line PVC/UPVC/CPVC

* PE/PPR Compound Pipe Extrusion Line PE/PPR

* Spiral Corrugated Pipe Extrusion Line

* PVC Fiber -Reinforced Pipe Extrusion Line PVC

* PVC Suction Hose Extrusion Line PVC

* PVC/WPC Window frame Profile / Door Board Extrusion Line PVC/WPC

* PET/PP Packing Belt Extrusion Line PET/PP

* PP/PE/ABS Plastic Plated Extrusion Line

* PVC Shinning/Semi-Shinning Foam Board Extrusion Line

* PP Hollow Grid Sheet Extrusion Line

* PP/PE Granulating Extrusion Line

*EPE Fruit foam net extrusion machine

*Auxiliary Equipment

CONTACT US

FAQ

Q: How can we guarantee quality?

A: Always a pre-production sample before mass production;

Always final inspection before shipment.

Q: What can you buy from us?

A: Single Wall Corrugated Pipe Machine, Double Wall Corrugated Pipe Machine, PVC/ PP

Water Supply Pipe Machine, WPC/PVC Profile and Sheet Profile Machine, PVC Fiber

Reinforced Pipe Machine etc.

Q: Why should you buy from us not from other suppliers?

A: Advanced production technology with design capability.

Reasonable price with good quality and best delivey time.

Our sales team will give prompt feedback within 24 hours.

Professional after sales service system.

Q: What service can we provide?

A: Accepted Delivery Terms: FOB, CFR, CIF, EXW, Express Delivery

Accepted Payment Currency: USD, EUR

Accepted Payment Type: T/T, L/C, MoneyGram, Credit Card, Western Union, Cash;

Language Spoken:English,Chinese,Spanish

Q: Are you machinery factory or trading company?

A: We are machinery factory

Q:If we have very special request for the production line, could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A: Our factory is in Jiaozhou Town, Qingdao City, Shandong Province, China. About 1 hours

from Qingdao International Ariport.

A: Always a pre-production sample before mass production;

Always final inspection before shipment.

Q: What can you buy from us?

A: Single Wall Corrugated Pipe Machine, Double Wall Corrugated Pipe Machine, PVC/ PP

Water Supply Pipe Machine, WPC/PVC Profile and Sheet Profile Machine, PVC Fiber

Reinforced Pipe Machine etc.

Q: Why should you buy from us not from other suppliers?

A: Advanced production technology with design capability.

Reasonable price with good quality and best delivey time.

Our sales team will give prompt feedback within 24 hours.

Professional after sales service system.

Q: What service can we provide?

A: Accepted Delivery Terms: FOB, CFR, CIF, EXW, Express Delivery

Accepted Payment Currency: USD, EUR

Accepted Payment Type: T/T, L/C, MoneyGram, Credit Card, Western Union, Cash;

Language Spoken:English,Chinese,Spanish

Q: Are you machinery factory or trading company?

A: We are machinery factory

Q:If we have very special request for the production line, could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A: Our factory is in Jiaozhou Town, Qingdao City, Shandong Province, China. About 1 hours

from Qingdao International Ariport.

Hot Searches