- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Sanlang

-

Name:

-

Polyester Wadding Comforter Production Line

-

Model:

-

SL-850T,SL-1230T,SL-1850T

-

Capacity:

-

100-150,150-200,200-300KG/H

-

Power:

-

33-45KW

-

Raw Material:

-

3-15D*32-64MM Polyester Fiber

-

Wadding Density:

-

60-800GSM

-

Final Products:

-

Wadding Batt

-

Application:

-

Comforter,Quilt,Blanket,Duvet

-

Whatsapp:

-

+86-18562862235

-

Company:

-

Manufacturer Since 2003

Quick Details

-

Weight (KG):

-

9000

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sanlang

-

Name:

-

Polyester Wadding Comforter Production Line

-

Model:

-

SL-850T,SL-1230T,SL-1850T

-

Capacity:

-

100-150,150-200,200-300KG/H

-

Power:

-

33-45KW

-

Raw Material:

-

3-15D*32-64MM Polyester Fiber

-

Wadding Density:

-

60-800GSM

-

Final Products:

-

Wadding Batt

-

Application:

-

Comforter,Quilt,Blanket,Duvet

-

Whatsapp:

-

+86-18562862235

-

Company:

-

Manufacturer Since 2003

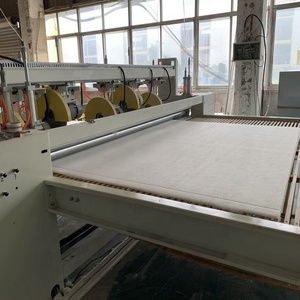

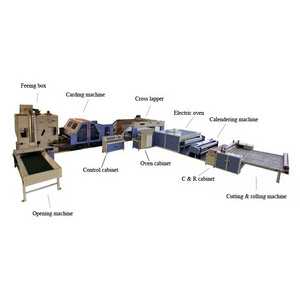

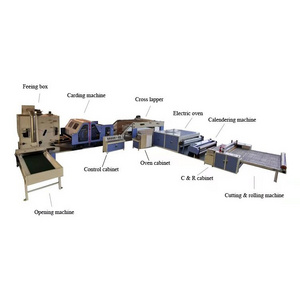

Polyester Wadding Sheet Production Line

1.Whole production line frequency conversion ,the running speed is adjustable,easy

operation,

According to customer demands,adopt different configurations,finished products can be used for

quilt,comforter,pillow,cushion,mattress and other home textile products

2.Open the compressed fiber raw materials into fluffy fibers and transport them to feeding box

3.To collect the fluffy fibers which delivered by the opening machine and evenly transport those fibers to carding machine

4.Opening and combing fiber into fibrous layer , after being combed by freedom rollers,the fiber in fibrous layer will be

intertwined more closely.

5.By folding the fiber layer back and forth, continuous formation of a fiber layer with a certain width and thickness

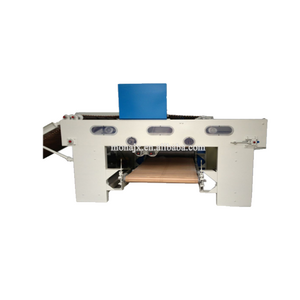

6.Adopt two pressure rollers working in opposite directions,by running at a differential speed,the wadding will be cut from

transverse,then can get a wadding sheet in certain thick,width and length

7.Automatic filling the wadding sheet into quilt case ,then put on quilting machine to sewing pattern

operation,

According to customer demands,adopt different configurations,finished products can be used for

quilt,comforter,pillow,cushion,mattress and other home textile products

2.Open the compressed fiber raw materials into fluffy fibers and transport them to feeding box

3.To collect the fluffy fibers which delivered by the opening machine and evenly transport those fibers to carding machine

4.Opening and combing fiber into fibrous layer , after being combed by freedom rollers,the fiber in fibrous layer will be

intertwined more closely.

5.By folding the fiber layer back and forth, continuous formation of a fiber layer with a certain width and thickness

6.Adopt two pressure rollers working in opposite directions,by running at a differential speed,the wadding will be cut from

transverse,then can get a wadding sheet in certain thick,width and length

7.Automatic filling the wadding sheet into quilt case ,then put on quilting machine to sewing pattern

|

Model

|

SL-850T

|

SL-1230T

|

SL-1850T

|

||

|

Floor Size

|

15*10*2.5M

|

15*10*2.5M

|

16*10*2.5M

|

||

|

Max Product Width

|

2800-3000-3200 OPTIONAL

|

|

|

||

|

Wadding Density

|

60-800GSM

|

|

|

||

|

Output

|

80-150KG/H

|

150-200KG/H

|

200-300KG/H

|

||

|

Power

|

33.5KW

|

37KW

|

43KW

|

||

|

Finished Product

|

Polyester Wadding(Wadding Batt)

|

|

|

||

Q1:

Warranty,Quality and Service

A:We provide one year warranty,within one year,If machine damaged,we provide parts free;

And we provide online guidance within 12 hours,lifetime service

Q2: Experience,Professional and Engineer

A:We are a home textile manufacturer with almost 20 years experience,Our engineer online eight hours every day,we will give best

guide before buying and after buying

Q3: Trust and Safety

A:We are a family business group,all of us working in this market and can only working in this field,we must do our best because

there is no way of escape,no matter when you have troubles,you can find us always

Q4: Advantage and Why choose us

A:We have are rich experience, professional team, never absent after-sales service

we helped many many customers in the world,we are growing up together with all of our customers

A:We provide one year warranty,within one year,If machine damaged,we provide parts free;

And we provide online guidance within 12 hours,lifetime service

Q2: Experience,Professional and Engineer

A:We are a home textile manufacturer with almost 20 years experience,Our engineer online eight hours every day,we will give best

guide before buying and after buying

Q3: Trust and Safety

A:We are a family business group,all of us working in this market and can only working in this field,we must do our best because

there is no way of escape,no matter when you have troubles,you can find us always

Q4: Advantage and Why choose us

A:We have are rich experience, professional team, never absent after-sales service

we helped many many customers in the world,we are growing up together with all of our customers

Hot Searches