- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

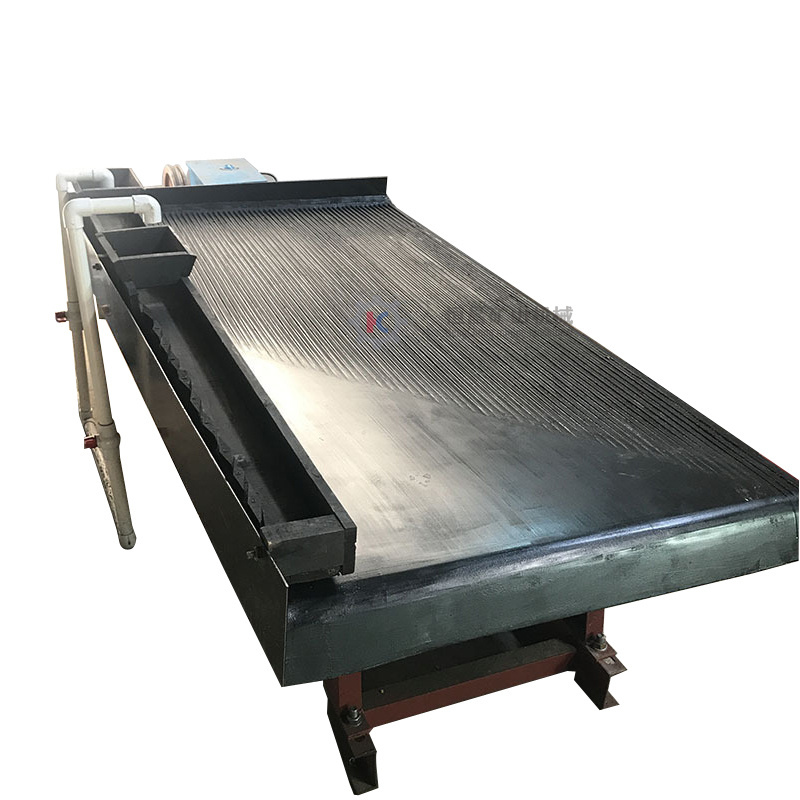

4450*1850*200mm for Vibrating Shaking Table

-

Weight:

-

800 KG

-

Name:

-

The Best 6S Gold Shaking Tables

-

operation:

-

easy

-

Quality:

-

very good

-

Test:

-

We can supply gold shaking table for client's sample testing

-

Deck of Gold Shaking table Material:

-

Fiberglass lined with polyurethane and corundum

-

Water:

-

Water can be recycling use for this type 6-S Gold Shaking table

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

capacity:

-

1-2t/h

-

other type:

-

double layer shaking table

-

length of the deck:

-

4.5m

Quick Details

-

Production Capacity:

-

0.8-2 t/h

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Hengchang Gold Processing Plant

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

4450*1850*200mm for Vibrating Shaking Table

-

Weight:

-

800 KG

-

Name:

-

The Best 6S Gold Shaking Tables

-

operation:

-

easy

-

Quality:

-

very good

-

Test:

-

We can supply gold shaking table for client's sample testing

-

Deck of Gold Shaking table Material:

-

Fiberglass lined with polyurethane and corundum

-

Water:

-

Water can be recycling use for this type 6-S Gold Shaking table

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

capacity:

-

1-2t/h

-

other type:

-

double layer shaking table

-

length of the deck:

-

4.5m

Small Scale Gold Mining Machine Rock Gold Gravity Separator 2M Long Gold Shaking Table Shaker Tables For Small Miners

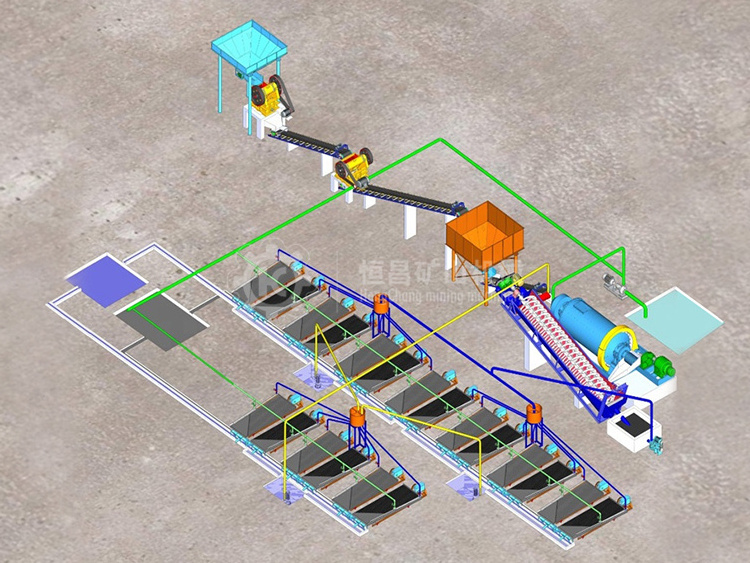

Gold Processing Plant

is a mine separation device for fine minerals working by gravity. They are effective in processing precious and base metal, rare metal and non-metallic minerals, widely used in separation for Gold, Silver, Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome, Manganese, Zircon, Lead, Zinc, Mercury, Copper, Aluminum, etc.

Gold Processing Plant

Introduction:

Gold Processing Plant is widely used for sorting minerals. Its main function is sorting the rough and concentrate mixture after minerals gravity separating. (Such as rough concentrate sorted by jig and shaking table). Process particle size is ranging from 2 mm to 0.074 mm. The separating effect is especially for minerals with a variety of sulfide minerals. It has the following advantages compared with the gold table: it is easy to observe changes of slurry on shaking table; easy to operate; it has many different specifications for choosing.

Gold Processing Plant is widely used for sorting minerals. Its main function is sorting the rough and concentrate mixture after minerals gravity separating. (Such as rough concentrate sorted by jig and shaking table). Process particle size is ranging from 2 mm to 0.074 mm. The separating effect is especially for minerals with a variety of sulfide minerals. It has the following advantages compared with the gold table: it is easy to observe changes of slurry on shaking table; easy to operate; it has many different specifications for choosing.

Gold Processing Plant Working Principle:

The working principle of Mineral Separation Equipment is to use the combined action of the specific gravity difference of sorted minerals, alternating movement of bed surface, and transverse oblique water flow and riffle (or notch groove), to allow loose layering of ores on the bed surface and fan-shaped zoning. Then different products can be produced.

This machine is composed of three parts, i.e. head of shaking table, surface of shaking table, as well as bearing and adjusting gradient.

1. Head of shaking table: This is eccentric connecting-rod type mechanism. The motor drives the eccentric shafts to rotate and the connecting rod to move up and down. When the connecting rod pushes down the toggle plate compression spring, the pull rod drives the table surface to move in the direction of table head. When the connecting rod pushes it upward, it, through the spring tension, drives the table surface to move in the opposite direction. When they are linked, the rotating motion of eccentric shaft is changed into horizontal alternating differential motion of table surface.

2. Shaking table for gold table surface: It is mainly composed of vibrating roof, steel skeleton, glass fiber reinforced plastics and wear-proof surface, feed water tank, feed chute, and draw bar. The table surface adopts steel skeleton FRP composite structure. That is, glass fiber reinforced plastics are pasted on steel skeleton to form a solid glass fiber reinforced plastic surface. Its above uses abrasion-proof materials to make surface and riffle (notch groove).

3. Bearing and Adjusting Gradient Mechanism: Shaker table for gold The bearing and adjusting gradient mechanism is mainly composed of shaking support plate, adjusting seat board, saddle seat, and adjusting screw rod. The shaking support plate enables the table surface to make arc forward and backward alternating movement on vertical plane. The shaking support plate and shaking box are fixed on the adjusting seat board with gripping channel steel. When hand wheel regulating screw rod is used to get the adjusting seat board to rotate on the saddle seat, the Transverse gradient of table surface can be adjusted.

This machine is composed of three parts, i.e. head of shaking table, surface of shaking table, as well as bearing and adjusting gradient.

1. Head of shaking table: This is eccentric connecting-rod type mechanism. The motor drives the eccentric shafts to rotate and the connecting rod to move up and down. When the connecting rod pushes down the toggle plate compression spring, the pull rod drives the table surface to move in the direction of table head. When the connecting rod pushes it upward, it, through the spring tension, drives the table surface to move in the opposite direction. When they are linked, the rotating motion of eccentric shaft is changed into horizontal alternating differential motion of table surface.

2. Shaking table for gold table surface: It is mainly composed of vibrating roof, steel skeleton, glass fiber reinforced plastics and wear-proof surface, feed water tank, feed chute, and draw bar. The table surface adopts steel skeleton FRP composite structure. That is, glass fiber reinforced plastics are pasted on steel skeleton to form a solid glass fiber reinforced plastic surface. Its above uses abrasion-proof materials to make surface and riffle (notch groove).

3. Bearing and Adjusting Gradient Mechanism: Shaker table for gold The bearing and adjusting gradient mechanism is mainly composed of shaking support plate, adjusting seat board, saddle seat, and adjusting screw rod. The shaking support plate enables the table surface to make arc forward and backward alternating movement on vertical plane. The shaking support plate and shaking box are fixed on the adjusting seat board with gripping channel steel. When hand wheel regulating screw rod is used to get the adjusting seat board to rotate on the saddle seat, the Transverse gradient of table surface can be adjusted.

Table

Steel Support

Table Head

Table Support

|

Model

|

6S4450x1855x1546

|

LY3000x1620x1360

|

LY2100*1050*850

|

LY1100*500*430

|

|

Storke (mm)

|

8-22

|

6-30

|

12-38

|

9-17

|

|

Times of Stroke r(t/min)

|

210-350

|

210-320

|

250-460

|

280-460

|

|

Cross Slope (°)

|

1-4

|

0-10

|

0-8

|

0-10

|

|

Feed Size (mm)

|

2-0.074

|

2-0.074

|

2-0.074

|

2-0.074

|

|

Feed Density (%)

|

15-30

|

10-30

|

10-30

|

10-30

|

|

Water Consumption (t/h)

|

0.5-6

|

0.3-1.5

|

0.2-1.0

|

0.1-0.5

|

|

Capacity (t/h)

|

0.6-2.5

|

0.4-1.5

|

0.3-0.8

|

0.05-0.2

|

|

Power (kw)

|

1.1

|

1.1

|

1.1

|

0.55

|

|

Weight (kg)

|

800

|

500

|

350

|

150

|

Gold Processing Plant In India

used in gold separator processing plant

Gold Processing Plant In Australia

used in alluvial gold concentration

Gold Processing Plant in Morocco

used in zinc and chrome separation

Gold Processing Plant In Malaysia

used in copper separation and concentrator

Gold Processing Plant in Vietnam

used in river gold recovery

Gold Processing Plant in Indonesia

Used in rock gold concentration

Gold Processing Plant In Nigeria

used in tungsten ore separation

Gold Processing Plant In Tanzania

used in diamond and gold separator

Hot Searches