- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

MYHT-1-4

-

Product Name:

-

Removable for use hydraulic detector

-

Precission:

-

±1%

-

Flow Rate:

-

400L/MIN

-

Max.Pressure:

-

420 BAR

-

Overall dimensions:

-

530*320*260

-

Oil temperature range:

-

-20℃ -150℃

-

Weight:

-

24kg

-

Brand:

-

Highland pressure gauge manometer

-

Model:

-

MYHT-1-4 pressure gauge manometer

-

Application:

-

Pressure gauge manometer for hydraulic pump,motor checking

Quick Details

-

Warranty:

-

1 year

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HIGHLAND

-

Model Number:

-

MYHT-1-4

-

Product Name:

-

Removable for use hydraulic detector

-

Precission:

-

±1%

-

Flow Rate:

-

400L/MIN

-

Max.Pressure:

-

420 BAR

-

Overall dimensions:

-

530*320*260

-

Oil temperature range:

-

-20℃ -150℃

-

Weight:

-

24kg

-

Brand:

-

Highland pressure gauge manometer

-

Model:

-

MYHT-1-4 pressure gauge manometer

-

Application:

-

Pressure gauge manometer for hydraulic pump,motor checking

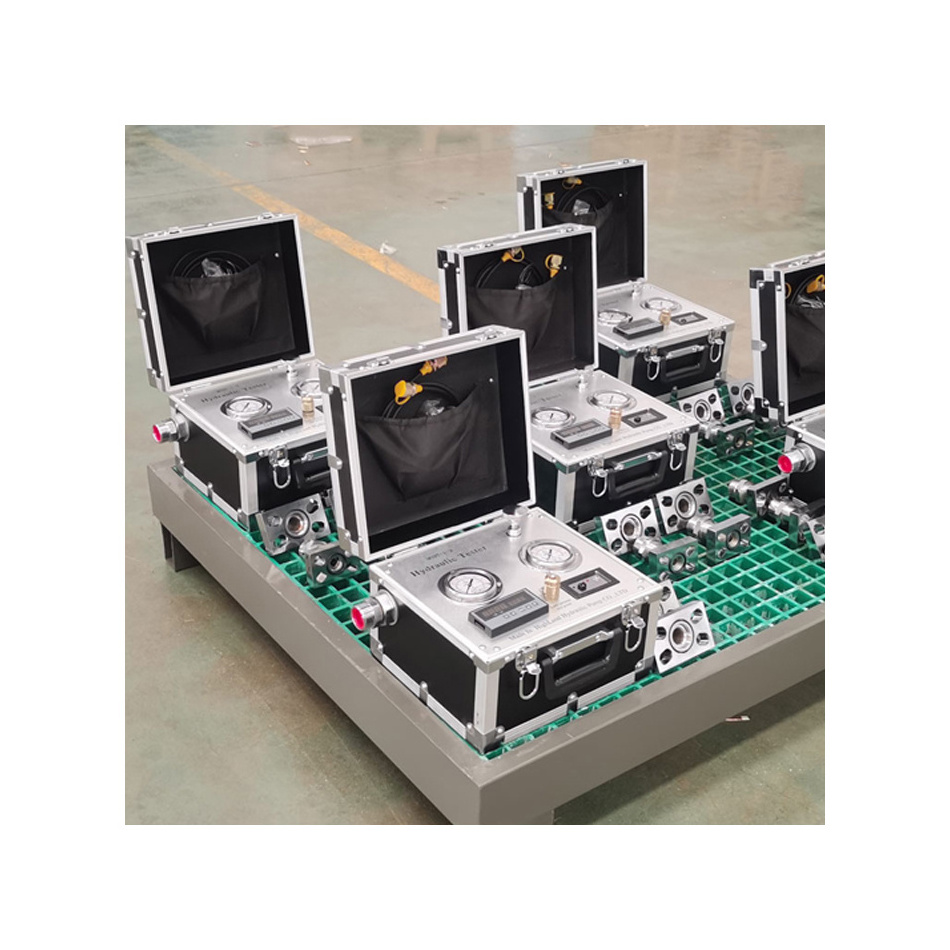

Digital hydraulic pressure tester industrial pressure gauges removable for use hydraulic detector

MYHT Hydraulic Tester, researched and produced by Jinan High Land Hydraulic Pump CO., Ltd. is a kind of practical and new type product with patent.

In the hydraulic loop system, the acquisition of breakpoints data and the measurement of flow rate, pressure and temperature of the system and components are able to be realized simultaneously. Through the data acquired MYHT Tester evaluates the performance of the system and components and judges the faults. It is widely used in testing and diagnosing for Hydraulic Pump, Hydraulic Motor and Hydraulic valve.

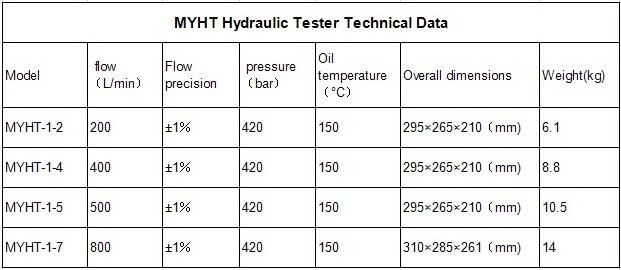

According to flow rate, there are four models for our hydraulic tester MYHT-1-2, MYHT-1-4, MYHT-1-5 and MYHT-1-7 .

- Accurate measurement of flow, pressure, peak pressure and temperature.

- Security hydraulic oil can flow in both directions, uniaxial loading, both to protect personnel protection instruments.

- Quick hydraulic equipment, hydraulic pumps, hydraulic motors, hydraulic valves, hydraulic cylinders online test. Simple connection.

- Light Meters Light weight, small size and easy to carry. Beautifully designed, easy to clean.

- Power Meter optional 12V lithium battery can be recharged, large capacity, long life.

In the design, MYHT Series Hydraulic Pressure Tester is a device that can be used for many years and with less trouble, If trouble arises after the quality guarantee period, it is available to do some simple inspection.

1. Loading Valve

If the Loading Valve can't load the system, remove the v alve spool and check if there are impurities on it or worn-out parts or or damages on seal ring.

2. Battery

The batteries for the meters are 12V lithium battery. Charge 4-8 hours before the tester work, and the battery can be used for 30 hours. It is necessary to charge the batteries with supporting charger, otherwise, explosion danger will easily arise.

3 . Flow Meter

When the Flow Meter doesn't display the reading, it is possible that the turbine rotor is stuck. Take turbine sensors apart and remove the impurities prevent of the turbine from flexibly rotating.

After refitted, check the flow readings. If the Flow Meter still not display any reading, please contact the manufacturer.

4. Prompt for testing the Servo Control Pump, Motor and valve. Special test procedure should have detailed regulations. It is necessary to learn the instructions from the relevant manufacturer of hydraulic equipment and hydraulic components.

5.

These components are with functions of increasing flow or pressure, and the design has fixed control mode such as push-pull servo control of the discharge of variable pump. It will cause the sharp rise of flow and pressure if try to use manual control instead of servo control.

This kind of control-losing test may lead to system’s failure, or components damage or human injury.

When MYHT - 1 Hydraulic Tester is installed at any position of hydraulic pipe, the hydraulic oil always flows from near the loading valves to the other end. If reverse connect arises, no pressure will be formed. In order to obtain the accurate measurements, the oil inlet and oiloutlet of the tester keep away above30cm away from the elbow, tees, valve.

Note: The loading valve must be unscrew counterclockwise before start-up of the equipment. It will cause human injury or equipment damage if the loading valve is fully closed!!!!!!

1.Before starting the equipment, loading must be unscrewed (left screwing to the end). Otherwise, danger easy arises.

2.Near the loading valve is high-pressure oil inlet, the other is outlet. Loading will not be realized if the inlet and outlet are connected at wrong position.

3.Please shut off the power when the instrument not in use.

4.This instrument is connected in series with the equipment system tested, and there should be no pressure in the oil outlet. Otherwise, the loading valve cannot screw.

5.When installing the oil inlet and oil outlet mouths joint, make sure you use the spanner to position the six-party joint of cabinet, and then connect to the fittings body.

Oil outlet ,Oil inlet, Upper Display Screen(Display the instantaneous flow),Loading valve,Under Display Screen(Fluid temperature),Coefficient Modifying keys of testing gauges should not adjust rashly.

More and more factories copy our hydraulic test bench. So from 2017 year we developed a new model test stand. The new model is more secure, space efficient and more private . It depends on your peference.

Our other products are hydraulic tester, hydraulic pump and motor