- Product Details

- {{item.text}}

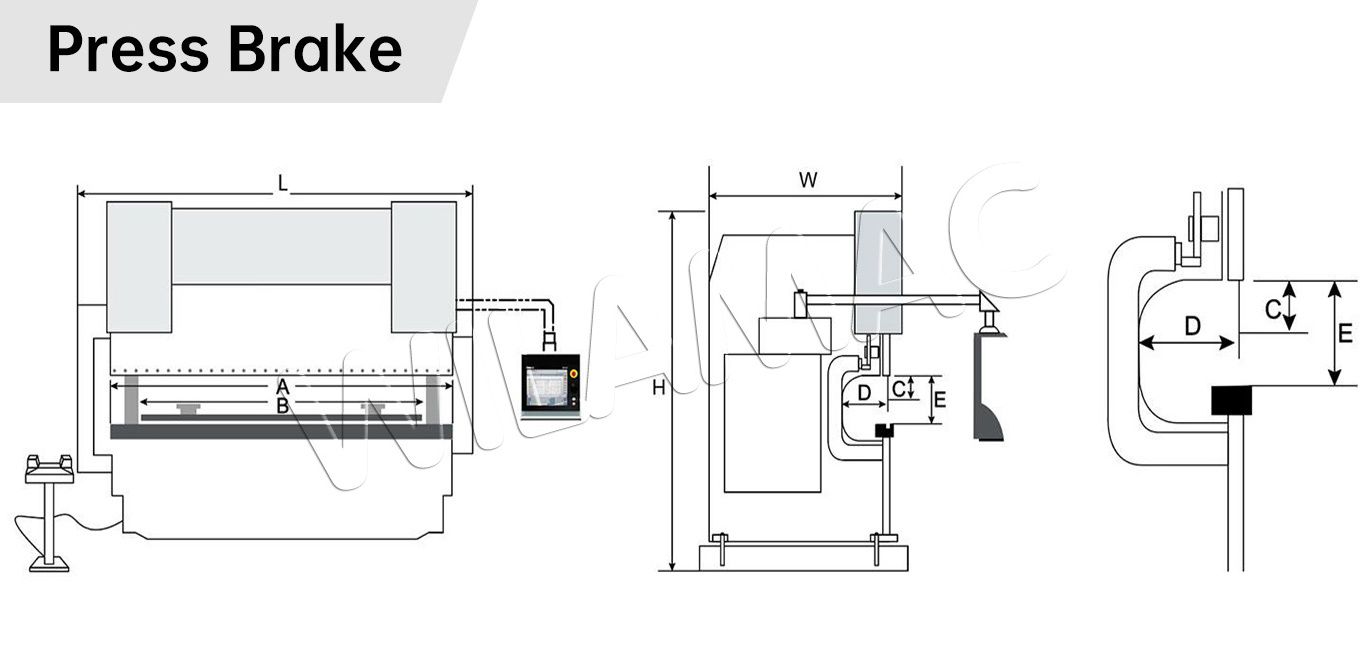

Quick Details

-

Throat Depth (mm):

-

320 mm

-

Width of Working Table (mm):

-

120 mm

-

Dimension:

-

2600*1450*2450

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

WILAMAC

-

Year:

-

2023

-

Weight (KG):

-

6000

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

New Product 2023

-

Steel Plate:

-

Sheet Bending

Quick Details

-

Machine Type:

-

Torsion Bar

-

Length of Working Table (mm):

-

2500

-

Slider Stroke (mm):

-

140 mm

-

Throat Depth (mm):

-

320 mm

-

Width of Working Table (mm):

-

120 mm

-

Dimension:

-

2600*1450*2450

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

WILAMAC

-

Year:

-

2023

-

Weight (KG):

-

6000

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

New Product 2023

-

Steel Plate:

-

Sheet Bending

Product Description

High Quality Bending Machine Hydraulic Press Brake Metal Sheet Bending Torsion Bar Machine

TP10s 4+1 axis Bending machines/ Press brake/ Metal bending machines/ Sheet metal bending machines/ Press brake machines/ CNC bending machines/ Steel bending machines/ CNC press brakes

1.Chrome coated cylinders are machined with 0,001 mm precision and pistons are specially hardened.

2.Clamps are user-friendly and machined with high precision.

3.Front support arms are slideable along machine length and easy to adjust.

4.Compact and well-known brand hydraulic system are produced according to CE standards.

5.Fast tool tightening.

6.Optic linear scales are sensitive up to ± 0,01 mm.

7.Synchronized working cylinders will give you the best bending result with their perfect repeatability ratio.

8. 2 axis ultra strong backgauge system with ± 0,01 mm repeatability.

9.By CNC controller, foldable back gauge fingers for reverse bending applications.

10.SIEMENS electrical system.

11.Automatic axis referencing when machine is turned on.

3.Front support arms are slideable along machine length and easy to adjust.

4.Compact and well-known brand hydraulic system are produced according to CE standards.

5.Fast tool tightening.

6.Optic linear scales are sensitive up to ± 0,01 mm.

7.Synchronized working cylinders will give you the best bending result with their perfect repeatability ratio.

8. 2 axis ultra strong backgauge system with ± 0,01 mm repeatability.

9.By CNC controller, foldable back gauge fingers for reverse bending applications.

10.SIEMENS electrical system.

11.Automatic axis referencing when machine is turned on.

|

Model

|

Nominal pressure

(KN)

|

Bending length (mm)

|

Between columns

(mm)

|

Throat depth (mm)

|

Stroke (mm)

|

Open height (mm)

|

Main power(KW)

|

|

30T-1600

|

300

|

1600

|

1295

|

200

|

80

|

370

|

3

|

|

63T-2500

|

630

|

2500

|

2000

|

280

|

120

|

380

|

5.5

|

|

80T-2500

|

800

|

2500

|

2000

|

280

|

120

|

390

|

7.5

|

|

80T-3200

|

800

|

3200

|

2600

|

280

|

120

|

390

|

7.5

|

|

100T-3200

|

1000

|

3200

|

2600

|

320

|

140

|

410

|

7.5

|

|

125T-3200

|

1250

|

3200

|

2600

|

320

|

140

|

410

|

11

|

|

125T-4000

|

1250

|

4000

|

3200

|

320

|

140

|

410

|

11

|

|

160T-3200

|

1600

|

3200

|

2600

|

380

|

200

|

460

|

15

|

|

160T-4000

|

1600

|

4000

|

3200

|

380

|

200

|

460

|

15

|

|

200T-3200

|

2000

|

3200

|

2600

|

380

|

200

|

460

|

15

|

|

250T-4000

|

2500

|

4000

|

3200

|

400

|

200

|

460

|

20

|

|

300T-6000

|

3000

|

6000

|

4900

|

420

|

250

|

480

|

30

|

(The parameters are provided for reference only!)

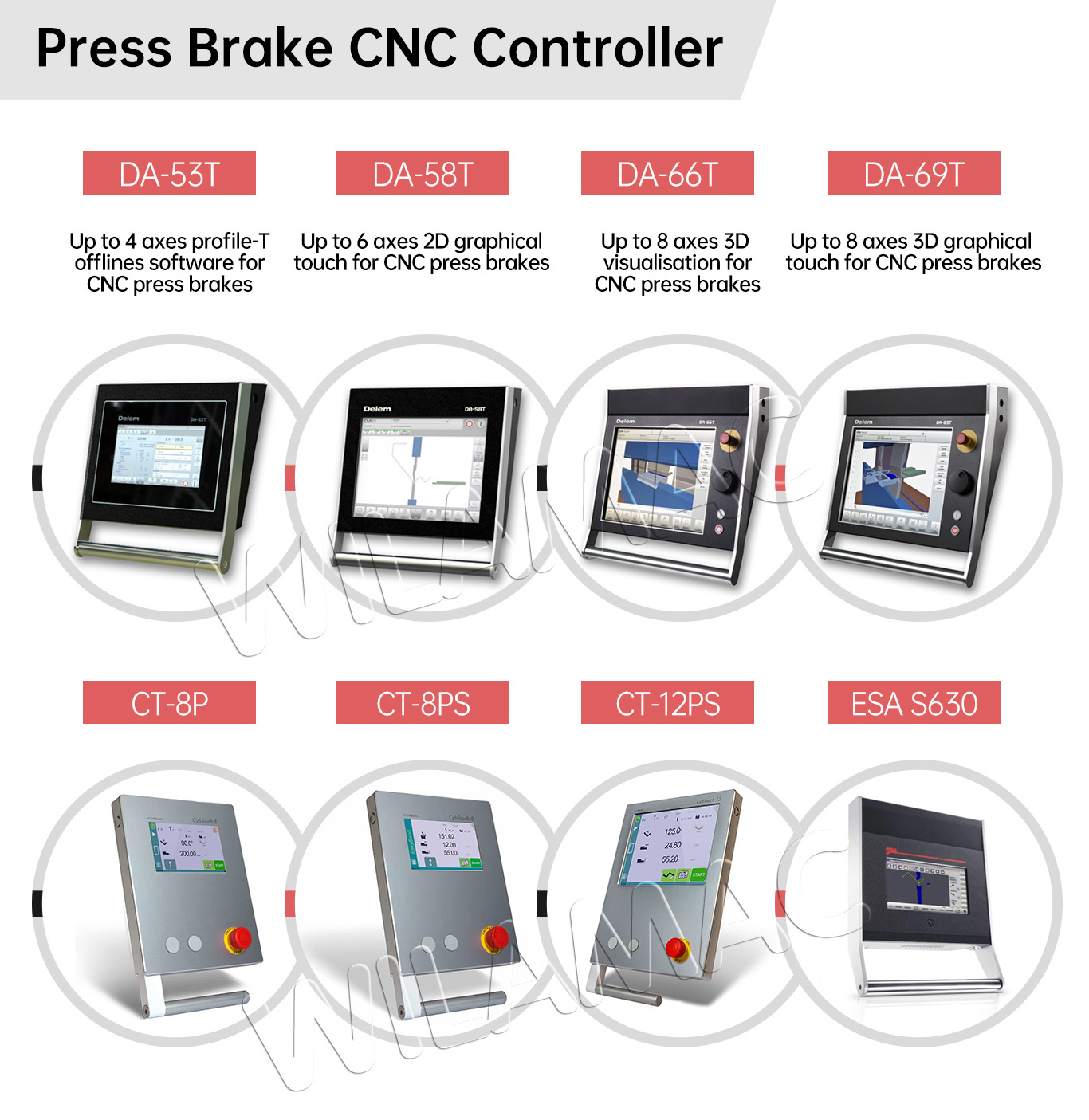

(we also have other press brake controllers)

|

Main configuration list

|

|

|

|

CNC Control system

|

TP10S

|

|

|

Electrical components

|

Schneider Electrical from French

|

|

|

Hydraulic System

|

Bosch-Rexroth from Germany

|

|

|

Main Motor

|

Siemens from Germany

|

|

|

Backgauge

|

Accurate positioning control X,R

|

|

|

Ball screw/ Liner guide

|

HIWIN from Taiwan

|

|

|

Foot switch

|

KACON from South Korea

|

|

|

Tubing connector

|

EMB from Germany Brand

|

|

|

Hydraulic Pump

|

Sunny from America

|

|

Detailed Images

1.Through the Solidworks of Stress analysis

2.

Framework by heat treatment

3.TP10S CNC System

4. Electrical cabinet with IP54 grade

5.Schneider Electric Components

6. Servo Motor

7.Hydraulic System, Bosch-Rexroth

8. SUNNY Pump

9.Crowning System (Not required below 3200 mm)

10. Magnetic scale

11.Quick clamp

12. Supporting arms

13.Ball screw and linear guide

14.Finger block

15.EMB Tubing connector

16.SIEMENS Motor

17.Light curtain (optional)

18.Laser protective device (optional)

19.Torsion-bar with rack structure

20.Press brake punch and die tool

21.Servo control R axis

22.Multifunctional Foot Switch

This is a

Mexican

customer who came to visit our press brake factory

Press Brake Toolings

Our Service

Packing & Delivery

Certifications

Contact us

Request a free quotation! Contact now!

Email:emily@wilacnc.com

Whatsapp NO:

+86 177 5557 6862

Wechat/phone:

+86 177 5557 6862

Hot Searches