- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Safed

-

Dimension(L*W*H):

-

1.3*1.05*2.05 m

-

Product Name:

-

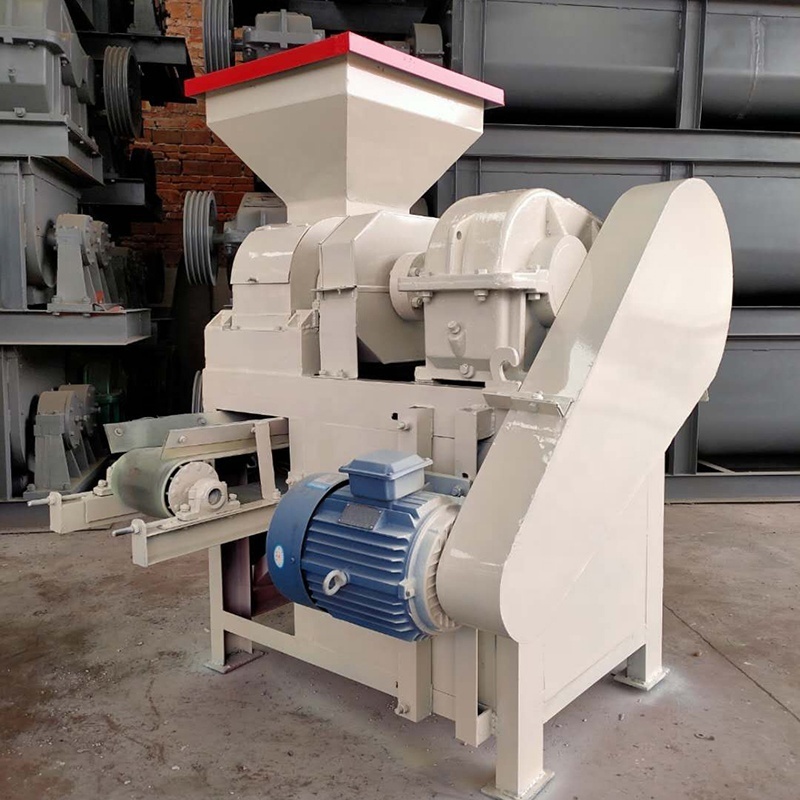

briquetting machine four roller press coal briquetting machine price

-

Color:

-

as buyer's request

-

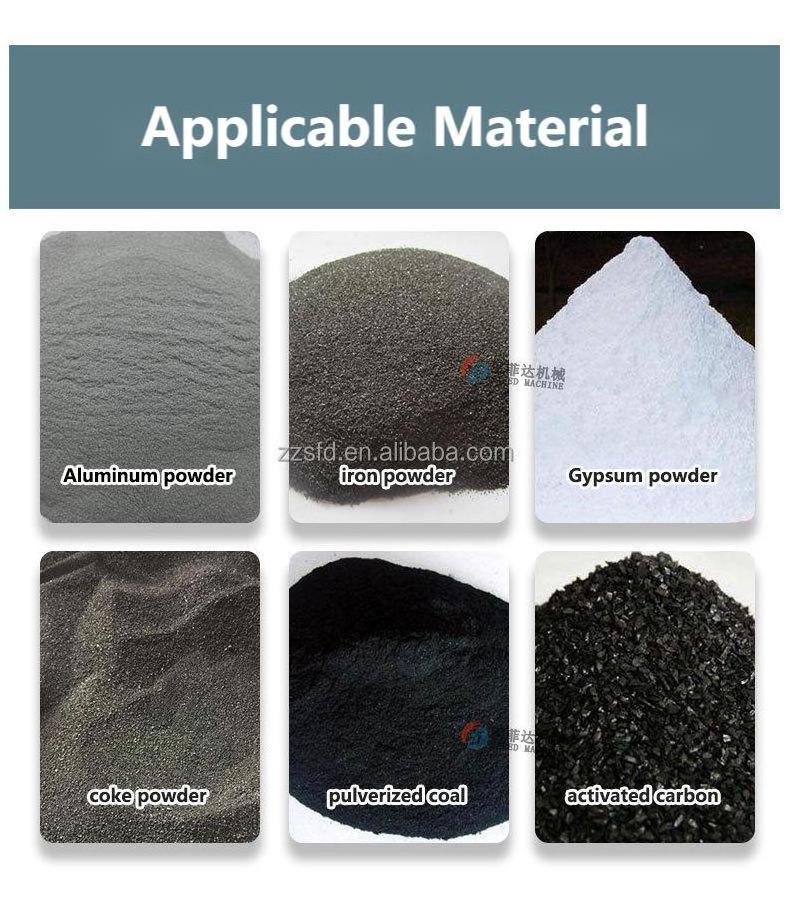

Raw material:

-

Coal powder,Charcoal powder,carbon black powder ,etc

-

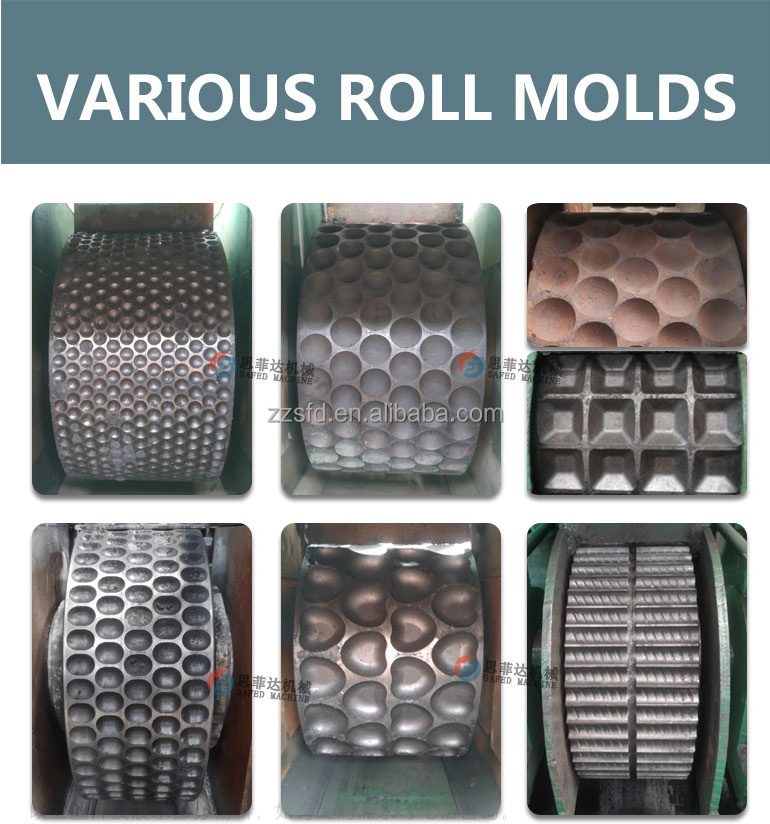

Briquette shape:

-

round,square,pillow or bread shape

-

Usage:

-

Make coal briquettes with high density

-

Out capacity:

-

4-6t/h

-

roller Diameter:

-

360mm

-

roller Wideth:

-

250mm

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

ISO,CE

Quick Details

-

Weight (KG):

-

500

-

Marketing Type:

-

Hot Product 2023

-

Production Capacity:

-

4-6t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Safed

-

Dimension(L*W*H):

-

1.3*1.05*2.05 m

-

Product Name:

-

briquetting machine four roller press coal briquetting machine price

-

Color:

-

as buyer's request

-

Raw material:

-

Coal powder,Charcoal powder,carbon black powder ,etc

-

Briquette shape:

-

round,square,pillow or bread shape

-

Usage:

-

Make coal briquettes with high density

-

Out capacity:

-

4-6t/h

-

roller Diameter:

-

360mm

-

roller Wideth:

-

250mm

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

ISO,CE

Product Description

Charcoal ball briquitte machine:

Ball pressing machine can be used to press pulverized coal, iron powder, coke coal, aluminum powder, iron filings, iron oxide, carbon powder, charcoal powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke and other powder, powder, waste, waste slag, widely used in resistant materials, power plants, metallurgy, chemical industry, energy, transportation, heating and other industries, after the ball pressing mechanism for forming materials, energy saving and environmental protection, It is convenient for transportation, improves the utilization rate of waste materials, and has good economic and social benefits.

Raw materials requirements:

coal powder, charcoal powder, metallic powder (FeSi powder), iron scale, iron sludge, precipitator dust, iron concentrate, raw material powder, manganese ore fines, slime peat, fireproof material, desulfurized gypsum,etc

Raw materials requirements:

coal powder, charcoal powder, metallic powder (FeSi powder), iron scale, iron sludge, precipitator dust, iron concentrate, raw material powder, manganese ore fines, slime peat, fireproof material, desulfurized gypsum,etc

Product Parameter

|

Model

|

Power

|

Capacity

|

Diameter of roller

|

Width of roller

|

Size

|

Weight(kg)

|

|

SFD-290

|

5.5 kw

|

1-3 t/h

|

290 mm

|

200mm

|

1.24x1.07x1.44 m

|

1300

|

|

SFD-360

|

7.5 kw

|

4-6 t/h

|

360 mm

|

250mm

|

1.3x1.15x2.05 m

|

1850

|

|

SFD-400

|

11kw

|

6-7 t/h

|

400mm

|

300mm

|

1.65x1.50x2.40 m

|

4000

|

|

SFD-450

|

15kw

|

8 t/h

|

450mm

|

300mm

|

1.65x1.50x2.40 m

|

4200

|

|

SFD-500

|

18.5kw

|

8-10 t/h

|

500mm

|

350mm

|

1.75x1.60x2.60 m

|

4500

|

|

SFD-650

|

30kw

|

10-15 t/h

|

650mm

|

380mm

|

2.2x2.2x2.8 m

|

5000

|

|

SFD-850

|

55kw

|

15-20 t/h

|

650850mm

|

650mm

|

3.5x3.5x3 m

|

10000

|

|

SFD-1000

|

75kw

|

20-30 t/h

|

1000mm

|

850mm

|

4.5x4.5x3 m

|

15000

|

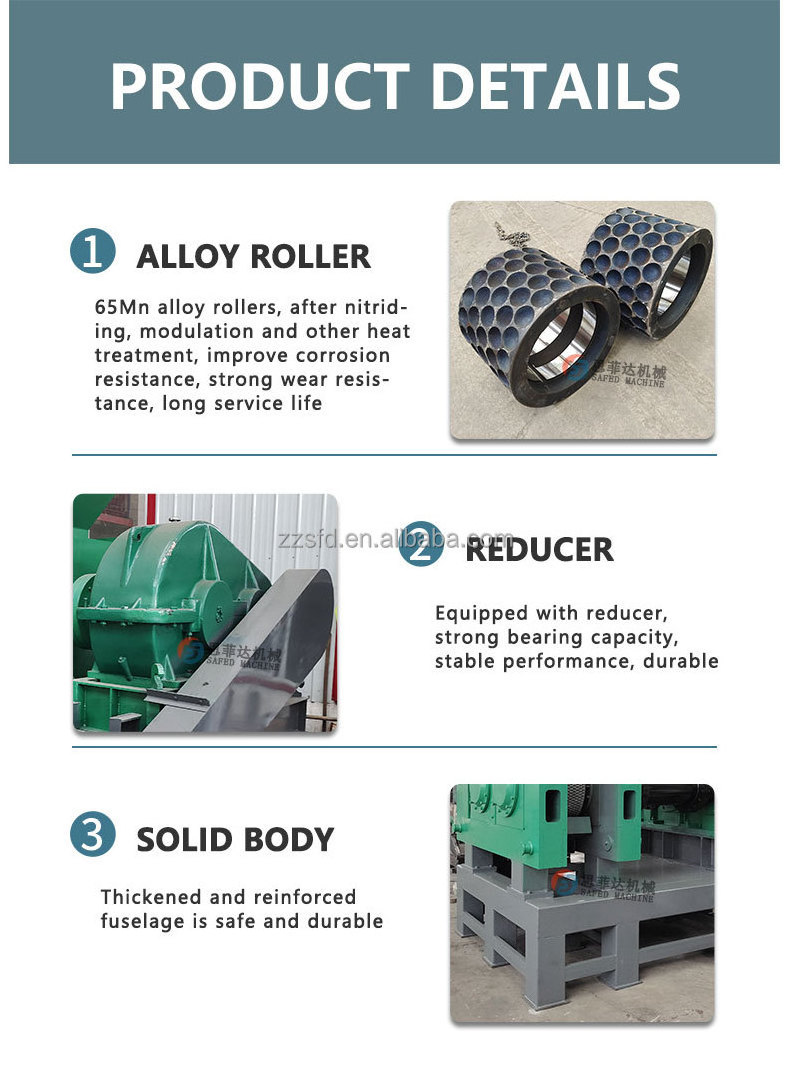

Product Details

Briquette Charcoal Making Machine:

Ball press roller is cast with 65 manganese. After special heat treatment, the hardness can reach more than 58 degrees. The roller is assembled in combination and can be replaced after wear. The ball press of mineral powder has a buffer device, which can better protect the equipment from the impact of hard objects. Mineral powder ball press is designed with ball bowl adjustable device so that the two roller ball bowl is always within the adjustable range, never dislocation.

Production Flow

Working principle of charcoal ball briquitte machine:

From the storage silo, the material is fed into the molding machine hopper evenly by the quantitative device. Then the regulation board on the hopper make the materal evenly enter into the middle of the roller; the reverse operating roller compress the material and the forming pressure increases gradually, at the centerline of the roll the forming pressure reaches its maximum value, once the material through the line, the molding pressure rapidly decrease so that the material forms into ball shape and smoothly discharge the ball.

Delivery site

Hot Searches