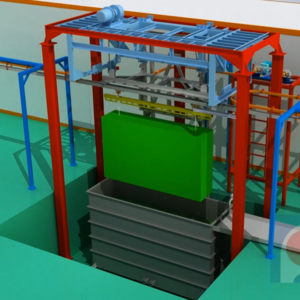

Front oven, lifter, rear oven, electrical control cabinet; accessories: rack, bucket, link guide and other components.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

As requested

-

Power:

-

As requested

-

Dimension(L*W*H):

-

Non standard

-

Color:

-

Avaliable

-

Application:

-

Metal Surface Finishing

-

After-sales Service Provided:

-

Field Installation, commissioning and training, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Control System:

-

Electric Control Cabinet

-

Technology:

-

Electrostatic Powder Spraying Technology

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

ISO

-

Weight:

-

in kind prevail

Quick Details

-

Machine Type:

-

coating machine

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ours coating

-

Voltage:

-

As requested

-

Power:

-

As requested

-

Dimension(L*W*H):

-

Non standard

-

Color:

-

Avaliable

-

Application:

-

Metal Surface Finishing

-

After-sales Service Provided:

-

Field Installation, commissioning and training, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Control System:

-

Electric Control Cabinet

-

Technology:

-

Electrostatic Powder Spraying Technology

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

ISO

-

Weight:

-

in kind prevail

PLASTIC DIP COATING

Products are widely used in many fields, strong corrosion-resistant, environmentally friendly pollution-free, bright colors,

service life up to 30 years.

Dipping is a heating process: metal preheating, dipping, and curing. During the dipping, the heated metal sticks to the

surrounding materials. The hotter the metal is, the longer the dipping time is and the thicker the material is. Naturally,

temperature and dip shapes are the keys to determining how much plastisol sticks.

The dipping materials are various plastic powders.

Dipping machine is divided into ordinary type, semi-automatic type, fully automatic type.

MAIN PARTS:

PROCESS:

Dipping is a heating process: metal preheating, dipping, and curing.

|

|

|

|

|

Size

|

It depends

|

|

|

Weight

|

It depends

|

|

|

Packaging Details

|

The normal package is film and carton. If container is too tigher, we will use pe film for packing or pack it according to customers special request.

|

|

Pre-Sales Service

* Free inquiry and consulting support.

* Free drawing design

* Free pick-up and hotel booking

* Free factory visit.

After-Sales Service

* Install the machine and commissioning

* Training how to use the machine.

* Engineers available to service machinery overseas.

* 24h online service