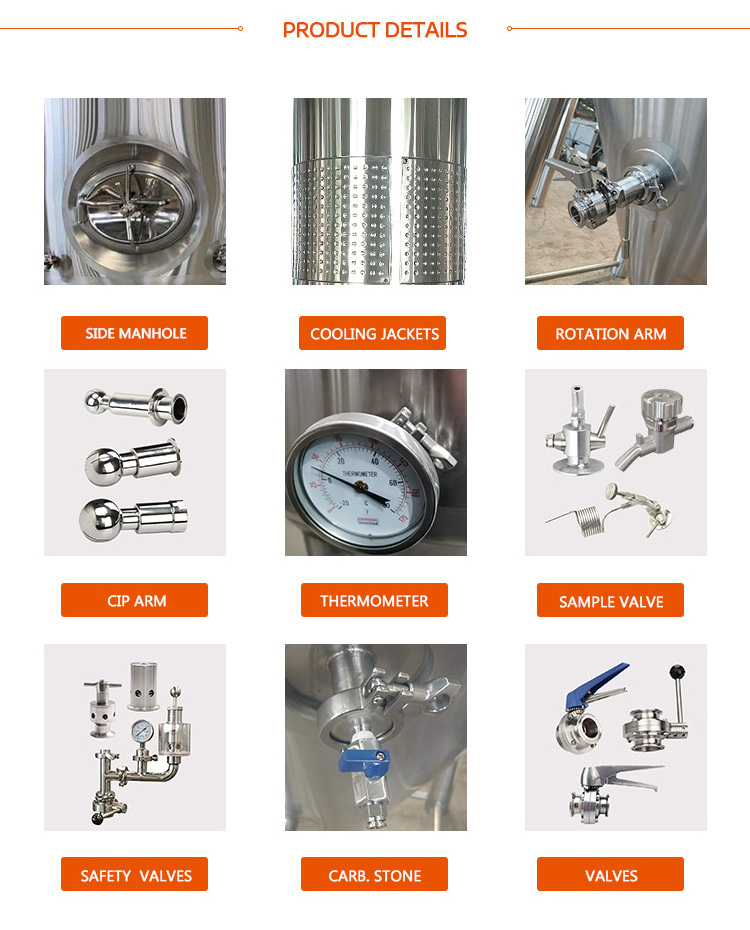

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Depending

-

Dimension(L*W*H):

-

Depending

-

Weight:

-

400 KG

-

Core Components:

-

Beer Tank

-

Polishing:

-

0.4-0.6um/Mirror Polished

-

Shipment time:

-

45 days

-

relevant equipment:

-

2000L beer fermenter

-

Function:

-

Fermentation Barrel

-

MOQ:

-

1 Set

-

material:

-

stainless steel

-

weld:

-

argon-arc welding

-

Control system:

-

PID controller

-

Cooling Jacket:

-

Dimple Cooloing Jacket

-

Package:

-

Suitable for long marine transport

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

RAINBOW MACHINERY

-

Voltage:

-

220-415V

-

Power:

-

Depending

-

Dimension(L*W*H):

-

Depending

-

Weight:

-

400 KG

-

Core Components:

-

Beer Tank

-

Polishing:

-

0.4-0.6um/Mirror Polished

-

Shipment time:

-

45 days

-

relevant equipment:

-

2000L beer fermenter

-

Function:

-

Fermentation Barrel

-

MOQ:

-

1 Set

-

material:

-

stainless steel

-

weld:

-

argon-arc welding

-

Control system:

-

PID controller

-

Cooling Jacket:

-

Dimple Cooloing Jacket

-

Package:

-

Suitable for long marine transport

Product Description

Micro beer brewing equipment 2000L beer fermenters used brewery equipment for sale

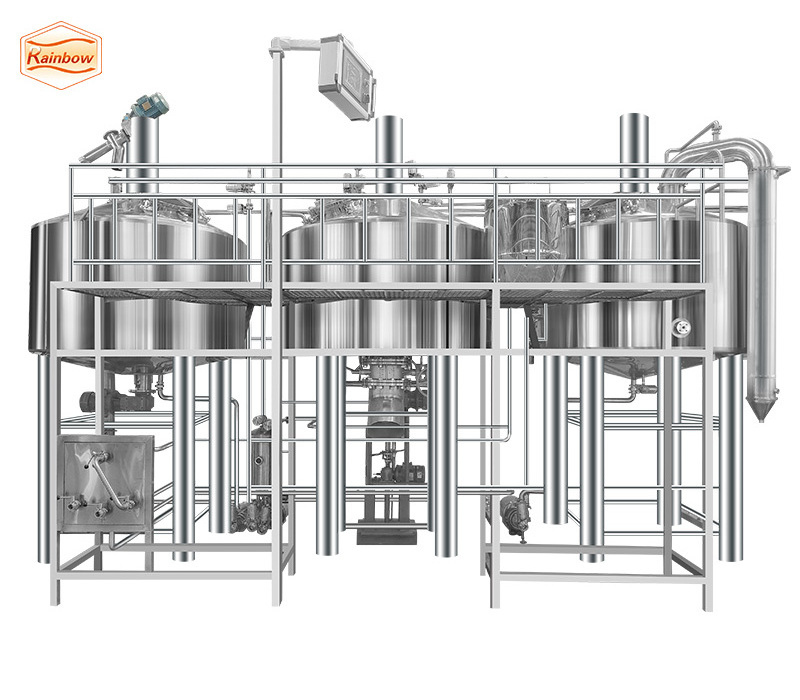

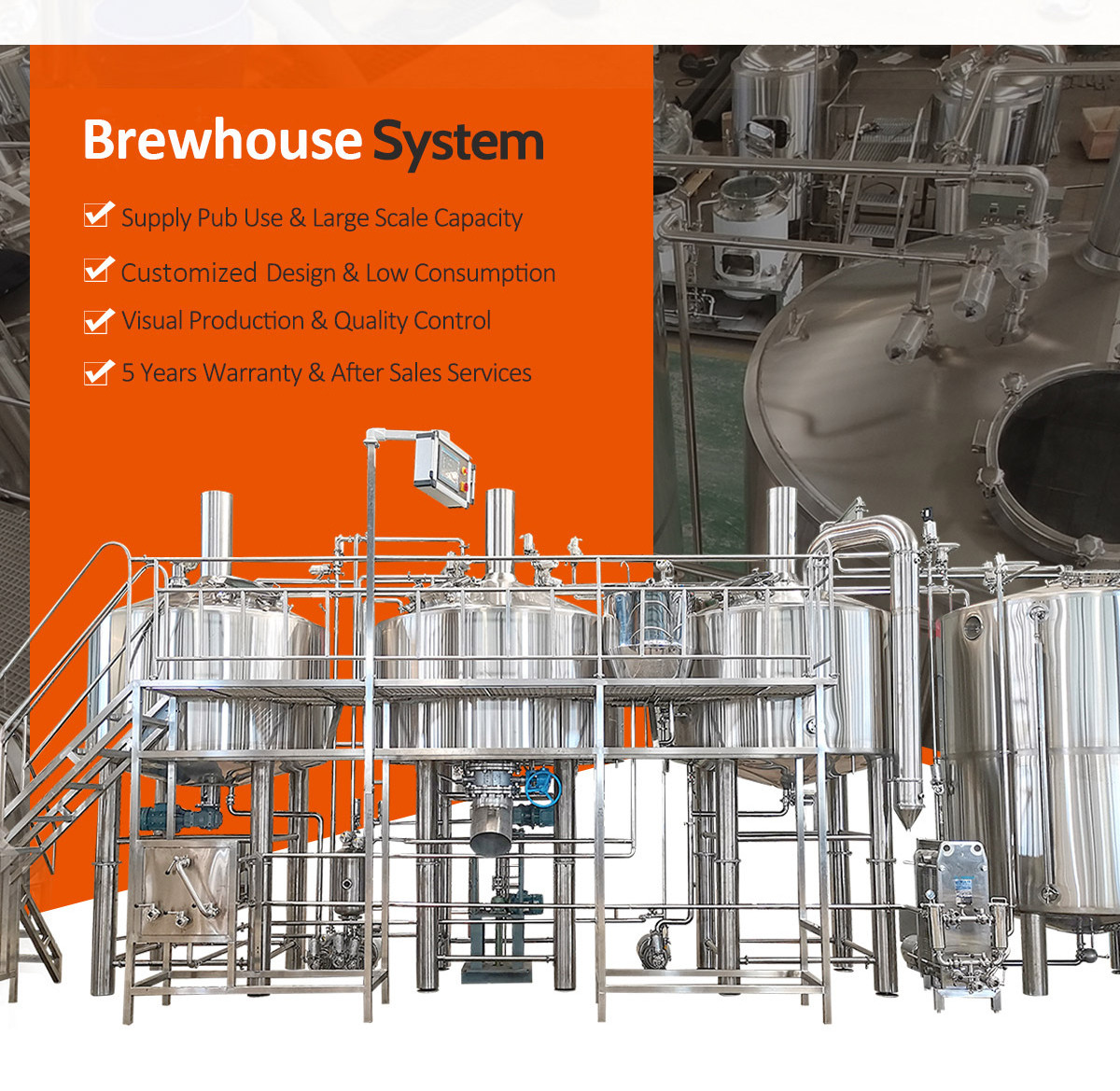

Brewhouse

Vessels:

Regular: MLT+BKW+HLT.

Mash/Brew Kettle +Lauter & Whirlpool Tank.

Others: Mash, Lauter, Brew, Whirlpool, HLT, CLT.

Heating Method:

Steam Heating/Electric Heating/ Direct fire/Baine Marie/RIMS/HERMS

Specifications:

With 30% Total Volume

Dome top and cone bottom; bottom cone 160 degree

Interior Shell: SUS304

Exterior Shell: SUS304

Insulation: PU/Rockwool T 100mm

100% TIG welding with pure argon gas shield

Interior Finish: 0.4~0.6μm/ Mirror Polishing

Top mounted manhole

360° CIP spraying ball

Thermowell with high accuracy temperature sensor: PT100

MLT with agitator with motor reducer, CE/UL Listed

MLT with side manhole for spent grains

MLT with easy-clean and detachable sparging arm

MLT with easy-clean and detachable false bottom

BKW with tangential inlet for whirlpool function

Plate Heat Exchanger (China Top Brand)

2 stages for Glycol water and City water

SUS 304 Plates and frame

Wort and HLT Pumps:-CE/UL Listed

Oxygenator

Brewhouse pipelines and Valves

SUS 304 Working Platform

Optional:

-Grist Case

-Wort Buffer Tank

-Platform with Sink

-Flow meter

-Pneumatic Valves

-Others

|

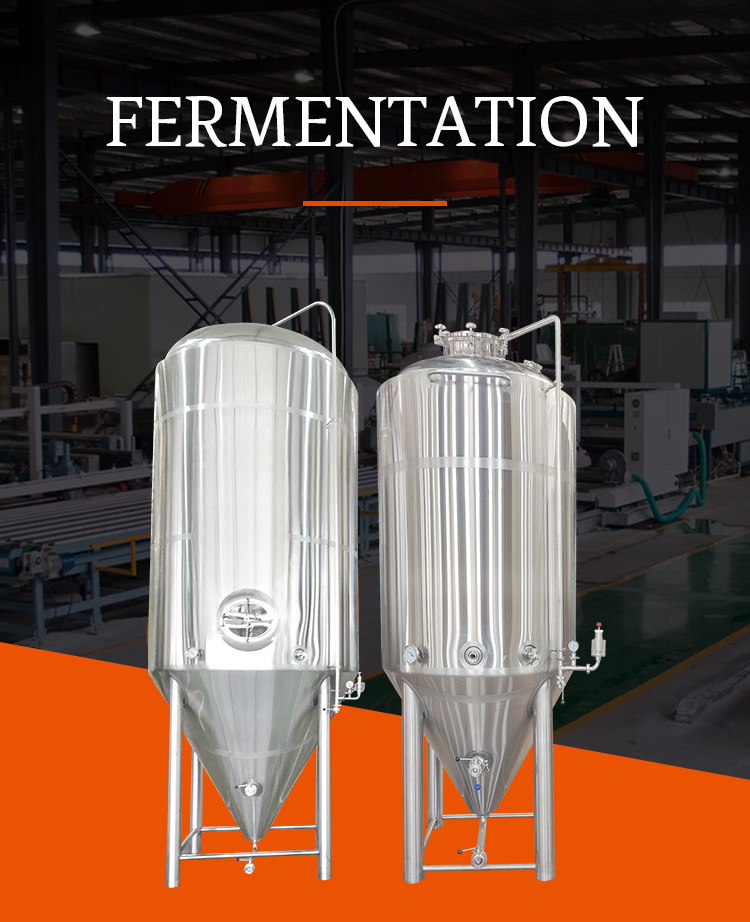

This stainless steel beer fermentation tank/beer container is one of the most important tanks in beer process. After the wort is

cooled, oxygen and brewing yeast is added to the fermenter, the yeast turns the fermentable sugars in the wort into alcol and carbon dioxide. |

|

|

|

|||

|

NO

|

Equipment

|

Specification

|

Quantity

|

|||

|

Fermentation system

|

Fermentation tank

|

2000 L

|

|

|||

|

-Material:

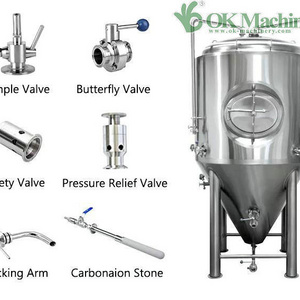

Inside wall, SUS 304, 3mm Outside wall, SUS 304, 1.5mm Cooling jackets, SUS 304, 1.5mm Insulation, PU, 100mm -Dome top with dry hop port -Top manway -Cone bottom, 60/72 degree -Cooling jackets on both cylinder and cone -Inside 360 rotating CIP ball -Thermowell, 8mm -Temperature sensor, Model: PT100 -Pressure gauge -Safety valve -Inside polishing 0.4-0.6 micron -Working pressure: 0.15Mpa -Testing pressure: 0.3Mpa -Wort piping and butterfly valves, ø32mm -Drainage piping and butterfly valve, ø38mm -3 legs with adjustable bolts |

|

|

|

|||

|

Spare parts

|

All the necessary hoses, pipes, valves, clamps/gaskets, thermometer and gauges…etc

|

|

|

|||

Hot Searches