- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

15-45 times/min

-

Air Pressure(MPa):

-

0.6 MPa

-

Sheet Thickness(mm):

-

0.1 - 1.5 mm

-

Heating Power (kW):

-

3 kW

-

Air Comsumption(L/min):

-

0.2 L/min

-

Water Comsumption(L/min):

-

0.6 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

WYLONG ZHD-420 coffee cup lid making machine

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

2500*1600*1000MM

-

Weight (T):

-

1.3 T

-

model ::

-

lid making machine

-

Sheet Materials:

-

PS.PET.PE

-

Cutting Frequency:

-

15--45(times/min)

-

Power:

-

380v/220v/50HZ

-

Stroke adjustable range:

-

0--300mm

-

Max. Forming Depth:

-

50mm

-

Max. Forming Area:

-

420/160mm

-

Motor Power:

-

4kw

-

Consumption:

-

>0.2m3/min

-

Overall Dimensions:

-

2500 /1600/1000mm

Quick Details

-

Max.Forming Height(mm):

-

50 mm

-

Forming Width (mm):

-

160 mm

-

Forming Length (mm):

-

420 mm

-

Production Speed(Cycles/min):

-

15-45 times/min

-

Air Pressure(MPa):

-

0.6 MPa

-

Sheet Thickness(mm):

-

0.1 - 1.5 mm

-

Heating Power (kW):

-

3 kW

-

Air Comsumption(L/min):

-

0.2 L/min

-

Water Comsumption(L/min):

-

0.6 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

WYLONG ZHD-420 coffee cup lid making machine

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

2500*1600*1000MM

-

Weight (T):

-

1.3 T

-

model ::

-

lid making machine

-

Sheet Materials:

-

PS.PET.PE

-

Cutting Frequency:

-

15--45(times/min)

-

Power:

-

380v/220v/50HZ

-

Stroke adjustable range:

-

0--300mm

-

Max. Forming Depth:

-

50mm

-

Max. Forming Area:

-

420/160mm

-

Motor Power:

-

4kw

-

Consumption:

-

>0.2m3/min

-

Overall Dimensions:

-

2500 /1600/1000mm

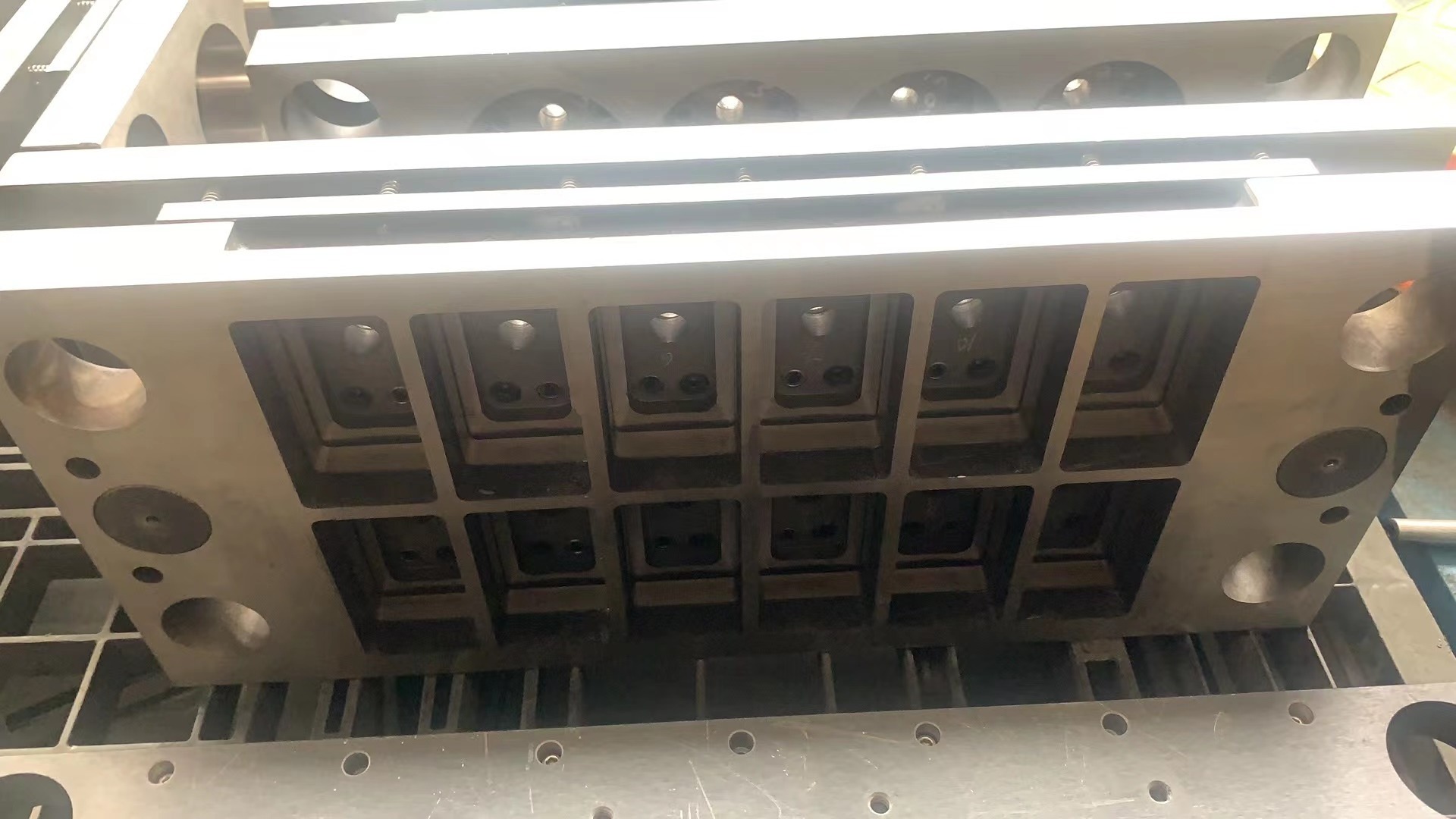

ZHD-420 coffee cup lid making machine

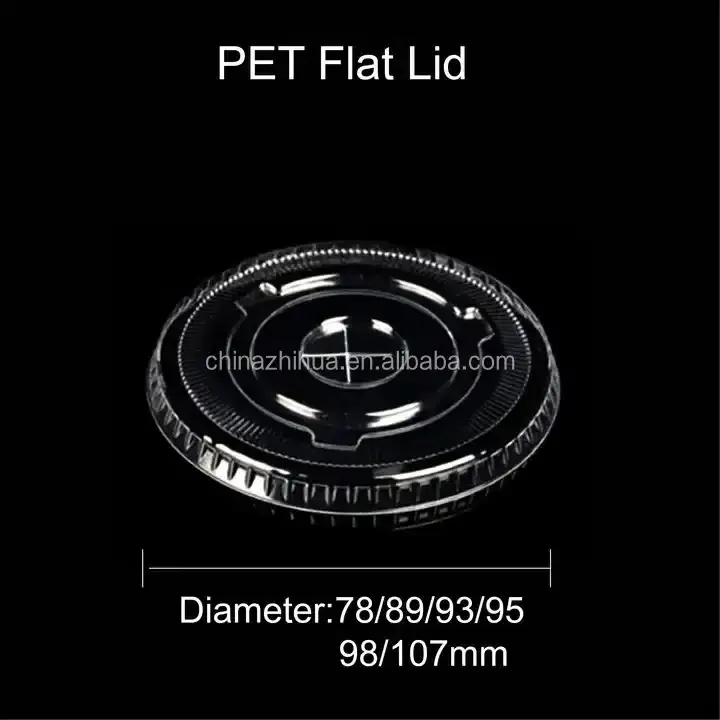

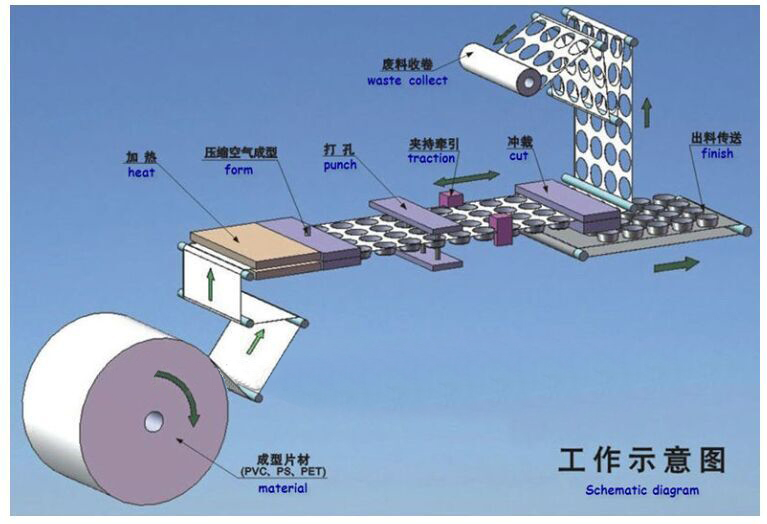

The plastic cup lid / cover thermoforming machine is specially designed for making different kinds of disposable plastic lids with Max. products height of 50 mm. The material of the lids can be PET, PS, PVC etc.

Main features:

1. The machine is designed and manufactured by the standard of “GMP” in medical industry and “QS” in food industry.

2. This machine can do forming, punching and blanking at the same time with servo motor to avoid the cross-contamination of product.

3. The forming heating plate can open and close automatically, also can delay to start, so as to control and lower the waste of the material during the production.

4. Easy to replace the mould, application to different specifications of products.

5. Design the mould according to customer’s requirements.

6. Applicable projects: the material of PET/PS/PVC.

Main features:

1. The machine is designed and manufactured by the standard of “GMP” in medical industry and “QS” in food industry.

2. This machine can do forming, punching and blanking at the same time with servo motor to avoid the cross-contamination of product.

3. The forming heating plate can open and close automatically, also can delay to start, so as to control and lower the waste of the material during the production.

4. Easy to replace the mould, application to different specifications of products.

5. Design the mould according to customer’s requirements.

6. Applicable projects: the material of PET/PS/PVC.

Specification

|

Model

|

ZHD-420 coffee cup lid making machine

|

|

Cutting Frequency

|

15-45(times/min)

|

|

Power

|

380v/220v/50HZ

|

|

Stroke adjustable range

|

160mm

|

|

Max. Forming Depth

|

50mm

|

|

Max. Forming Area

|

420*160mm

|

|

Motor Power

|

4kw

|

|

Consumption

|

>0.2m3/min

|

|

Pressure

|

0.6--0.8mpa

|

|

Overall Dimensions

|

2500*1600*1000mm

|

|

Weight

|

1300kg

|

Electric Parts Brand

|

Components:

|

Brand:

|

Origin:

|

|

The Touch Screen

|

SCHNEIDER

|

FRANCE

|

|

The PLC

|

SCHNEIDER

|

FRANCE

|

|

The Servo Motor

|

SCHNEIDER

|

FRANCE

|

|

The Servo Driver

|

SCHNEIDER

|

FRANCE

|

|

Temperature Controller

|

The Keqang Company

|

China

|

|

Circuit Breaker

|

SCHNEIDER

|

FRANCE

|

|

Frequency Converter

|

SCHNEIDER

|

FRANCE

|

|

Mini Relay

|

Omron Corporation

|

Japan

|

|

Solid-State Relay

|

Omron Corporation

|

Japan

|

|

The Encoder

|

Omron Corporation

|

Japan

|

|

The Main Motor

|

The GPG Group

|

Taiwan, China

|

|

The Air Cylinder

|

The Eda Company

|

China

|

|

The Reducing Valve

|

The Airtac International Group

|

Taiwan,China

|

|

The Programming

|

SCHNEIDER

|

FRANCE

|

|

The Solenoid Valve

|

The Airtac International Group

|

Taiwan, China

|

Machine Structure

Product Range

Related product

Certifications

Hot Searches