NPK fertilizer refers to 3 macronutrients, that is, the 3 main nutritional elements N, P, K that need to be supplemented first for plants, in order to improve the growth and productivity of plants.

- Product Details

- {{item.text}}

Quick Details

-

MF:

-

triple superphosphate (TSP)

-

Place of Origin:

-

Ba Ria-Vung Tau, Vietnam

-

Application:

-

monoammonium phosphate (MAP

-

Brand Name:

-

GGN

-

Model Number:

-

SR-VNPF

-

Product Name:

-

di-ammonium phosphate (DSP)

-

Other style:

-

ammonium polyphosphate liquid.

Quick Details

-

CAS No.:

-

7722-76-1, 7722-76-1

-

Purity:

-

99%, 98%

-

Other Names:

-

single superphosphate (SSP)

-

MF:

-

triple superphosphate (TSP)

-

Place of Origin:

-

Ba Ria-Vung Tau, Vietnam

-

Application:

-

monoammonium phosphate (MAP

-

Brand Name:

-

GGN

-

Model Number:

-

SR-VNPF

-

Product Name:

-

di-ammonium phosphate (DSP)

-

Other style:

-

ammonium polyphosphate liquid.

Product Description

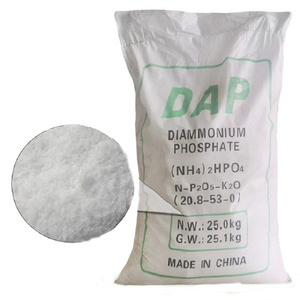

Fertilizer DAP Diammonium Phosphate dark brown color Bat Natural Guano fertilizers NPK Granulated Fertilizer From Vietnam

Earlier the original source of phosphorus (P) fertilizer was bones; as time passes, the supply of P fertilizer will get exhausted.

Today, rock phosphate is the only raw material in the form of P fertilizers. There are two types of rock phosphates: igneous and sedimentary; both have the same phosphate mineral, i.e., calcium phosphate of apatite group. The general formula for pure rock phosphate is Ca10(PO4)6(X)2, where X is F−, OH− or Cl−. These minerals are called apatites. The most common rock phosphate mined is fluorapatite, which contains impurities like CO3, Na and Mg. Carbonate-fluorapatite (francolite) is primary apatite mineral in the majority of phosphate rocks. The high reactivity of some phosphate rocks is due to the occurrence of francolite. The major deposits are found in the US followed by China, Morocco and Russia. The US produced about 33% of the world’s rock phosphate, although nearly 50% of the world reserves are in Morocco. P fertilizers are produced from either acid-treated or heat-treated rock phosphate to break the apatite bond and to increase the water soluble P content. There are many commercially available P fertilizers like rock phosphate, phosphoric acid, calcium orthophosphates, ammonium phosphates, ammonium polyphosphate and nitric phosphates.

|

Product Name

|

Phosphate Fertilizer DAP Diammonium Phosphate dark brown color

|

|

Type

|

Rock Phosphate

|

|

CAS No.

|

7722-76-1

|

|

Other Names

|

single superphosphate (SSP), triple superphosphate (TSP), di-ammonium phosphate (DSP), monoammonium phosphate (MAP), ammonium polyphosphate liquid.

|

|

Place of Origin

|

Vietnam

|

|

|

Ba Ria-Vung Tau

|

|

Release Type

|

Quick

|

|

State

|

GRANULAR

|

|

Brand Name

|

GGN

|

|

Model Number

|

SR-VNPF

|

|

Mobile

|

+84376540581

|

Specification

|

Descriptions

|

Unit

|

Common quality of FMP

|

High quality of FMP

|

|

P2O5

|

%

|

15-17

|

17-19

|

|

CaO

|

%

|

28-34

|

28-34

|

|

MgO

|

%

|

16-20

|

14-16

|

|

SiO2

|

%

|

25-30

|

20-25

|

|

Trace elements

|

p.p.pm

|

Fe, Mn. B, Zn, Mo, ...

|

Fe, Mn. B, Zn, Mo, ...

|

|

Size

|

mm

|

Sandy FMP: <3mm

Powder: <0.25mm

Granulated shape: 2-5mm

|

Sandy FMP: <3mm

Powder: <0.25mm

Granulated shape: 2-5mm |

|

Packing

|

KG/Bag

|

20KG, 25KG, 50KG, 1000KG

|

20KG, 25KG, 50KG, 1000KG

|

Process steps

Understanding the Manufacturing Process for NPK Granulated Mixtures:

The manufacturing process for NPK Granulated Mixtures typically involves several steps:

* The first step is to obtain the raw materials, including nitrogen sources (such as urea and ammonium nitrate), phosphorus

sources (such as superphosphate and monoammonium phosphate), and potassium sources (such as potassium chloride and potassium

sulfate).

* The raw materials are then weighed and blended together to achieve the desired NPK ratio. The mixture is then granulated to

form small, uniform particles for easier handling and application.

* Samples of the NPK Granulated Mixture are then taken and tested to ensure that they meet quality standards and have the correct

NPK ratio.

* The NPK Granulated Mixture is then packaged in bags, drums, or other containers and stored until it is ready for shipment.

* The NPK Granulated Mixture is then distributed to retail outlets or directly to farmers and gardeners.

The manufacturing process for NPK Granulated Mixtures typically involves several steps:

* The first step is to obtain the raw materials, including nitrogen sources (such as urea and ammonium nitrate), phosphorus

sources (such as superphosphate and monoammonium phosphate), and potassium sources (such as potassium chloride and potassium

sulfate).

* The raw materials are then weighed and blended together to achieve the desired NPK ratio. The mixture is then granulated to

form small, uniform particles for easier handling and application.

* Samples of the NPK Granulated Mixture are then taken and tested to ensure that they meet quality standards and have the correct

NPK ratio.

* The NPK Granulated Mixture is then packaged in bags, drums, or other containers and stored until it is ready for shipment.

* The NPK Granulated Mixture is then distributed to retail outlets or directly to farmers and gardeners.

After leaving the blast furnace, the semi-finished product of molten phosphate fertilizer is taken to the yard to be drained,

then:

- Dry and sieve to form granular phosphate fertilizer (particle size < 3 mm).

- Dry and grind to form powdered phosphate fertilizer (particle size < 0.25 mm).

- Dry, sieve, and put into the pelleting machine with a granulating agent, forming fused phosphate fertilizer in pellet form

(particle size 2 - 5mm).

Packing & Delivery

Packing Detail:

Standard packaging 25/50KG/PE/PP bag or according to customer's request, bag sealed with 2 sewing threads

Accept customer's packaging design

Delivery time:

Within 15-30days after down payment

Our product photos

Hot Searches