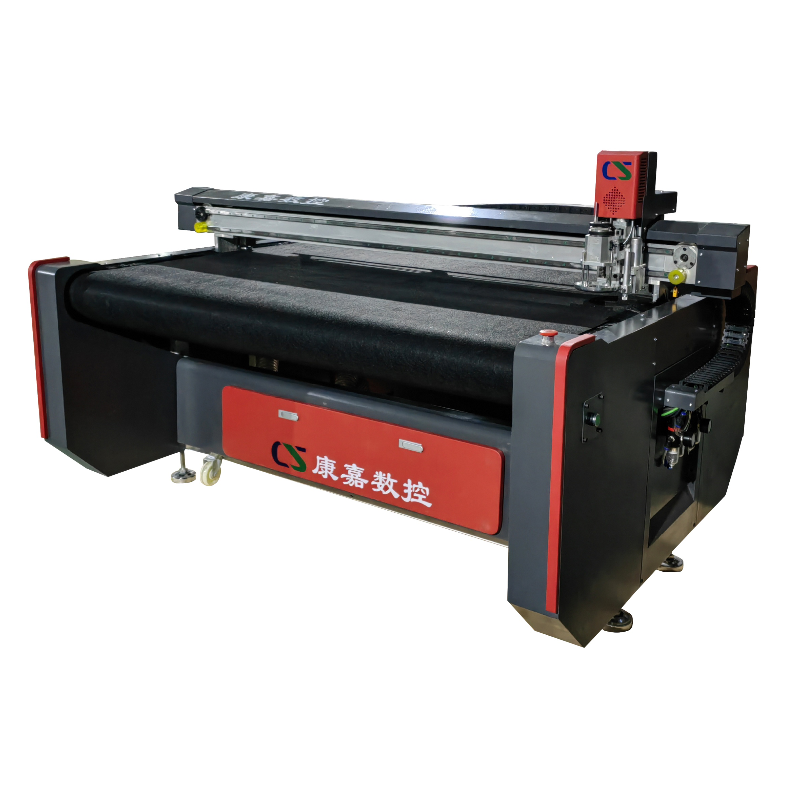

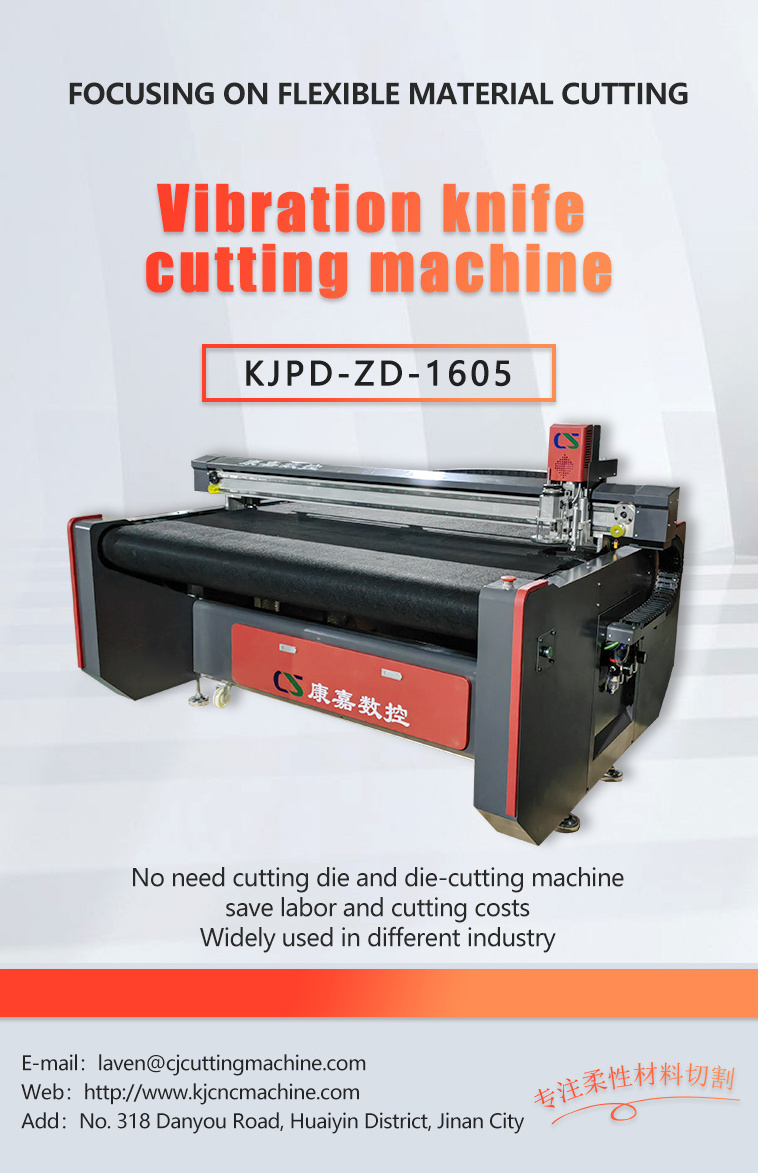

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Kangjia

-

Power:

-

9KW

-

Dimension(L*W*H):

-

1420* 2220*1250mm

-

Weight:

-

350 KG

-

Supported formats:

-

PLT, DXF, JDP

-

Control system:

-

PC

-

Driving mode:

-

Belt drive

-

Servo motor & drive:

-

Panasonic

-

Guide rail:

-

Brand :PMI (Yintai)

-

Body structure:

-

Body welding

-

Certification:

-

CE ISO9001

-

Safety device:

-

Mechanical anti-collision device + infrared ray

-

Cutting materials:

-

Flexible materials

-

Cutting tool:

-

Oscillating knife

Quick Details

-

Voltage:

-

220V/380V

-

Marketing Type:

-

2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Kangjia

-

Power:

-

9KW

-

Dimension(L*W*H):

-

1420* 2220*1250mm

-

Weight:

-

350 KG

-

Supported formats:

-

PLT, DXF, JDP

-

Control system:

-

PC

-

Driving mode:

-

Belt drive

-

Servo motor & drive:

-

Panasonic

-

Guide rail:

-

Brand :PMI (Yintai)

-

Body structure:

-

Body welding

-

Certification:

-

CE ISO9001

-

Safety device:

-

Mechanical anti-collision device + infrared ray

-

Cutting materials:

-

Flexible materials

-

Cutting tool:

-

Oscillating knife

Product Paramenters

|

model

|

PDS-SL1605

|

PDS-SL1625

|

PDS-SL1825

|

PDS-SL1830

|

PDS-SL2125

|

PDS-SL3030

|

PDS-DT1625

|

|

PowerEffective cutting area

|

500*1600(L*W)

|

2500*1600(L*W)

|

2500*1800(L*W)

|

3000*1800

|

2500*2100

|

3000*3000

|

2500*1600

|

|

Operating mode

|

automatic

|

automatic

|

automatic

|

automatic

|

automatic

|

automatic

|

automatic

|

|

Voltage

|

110V/220V/380V±10%, 50HZ 60HZ

|

110V/220V/380V±10%, 50HZ 60HZ

|

110V/220V/380V±10%, 50HZ 60HZ

|

110V/220V/380V±10%,50HZ 60HZ

|

110V/220V/380V±10%,50HZ 60HZ

|

110V/220V/380V±10%,50HZ 60HZ

|

110V/220V/380V±10%,50HZ 60HZ

|

|

Cutting speed

|

max 1400mm/s (Elite version)

|

max 1400mm/s (Elite version)

|

max 1400mm/s (Elite version)

|

max 1400mm/s (Elite version)

|

max 1400mm/s (Elite version)

|

max 1400mm/s (Elite version)

|

max 1400mm/s (Elite version)

|

|

Cutting thickness

|

≤50mm

|

≤50mm

|

≤50mm

|

≤50mm

|

≤50mm

|

≤50mm

|

≤50mm

|

|

Effective cutting area

|

9KW

|

9KW

|

9KW

|

9KW

|

9KW

|

9KW

|

9KW

|

|

Cutting accuracy

|

±0.1mm

|

±0.1mm

|

±0.1mm

|

±0.1mm

|

±0.1mm

|

±0.1mm

|

±0.1mm

|

|

Cutting Materials

|

Flexible Materials

|

Flexible Materials

|

Flexible Materials

|

Flexible Materials

|

Flexible Materials

|

Flexible Materials

|

Flexible Materials

|

|

Material fixation method

|

vacuum adsorption

|

vacuum adsorption

|

vacuum adsorption

|

vacuum adsorption

|

vacuum adsorption

|

vacuum adsorption

|

vacuum adsorption

|

|

Compatible software

|

KANGJIA software

|

KANGJIA software

|

KANGJIA software

|

KANGJIA software

|

KANGJIA software

|

KANGJIA software

|

KANGJIA software

|

|

Control system

|

LED touch screen

|

LED touch screen

|

LED touch screen

|

LED touch screen

|

LED touch screen

|

LED touch screen

|

LED touch screen

|

|

Transmission interface

|

USB /inernet port

|

USB /inernet port

|

USB /inernet port

|

USB /inernet port

|

USB /inernet port

|

USB /inernet port

|

USB /inernet port

|

|

Drive motor

|

Panasonic(Elite version)

|

Panasonic(Elite version)

|

Panasonic(Elite version)

|

Panasonic(Elite version)

|

Panasonic(Elite version)

|

Panasonic(Elite version)

|

Panasonic(Elite version)

|

|

Rail

|

PMI

|

PMI

|

PMI

|

PMI

|

PMI

|

PMI

|

PMI

|

|

Safety device

|

emergency stop button, infrared beam, anti-collision

|

emergency stop button, infrared beam, anti-collision

|

emergency stop button, infrared beam, anti-collision

|

emergency stop button, infrared beam, anti-collision

|

emergency stop button, infrared beam, anti-collision

|

emergency stop button, infrared beam, anti-collision

|

emergency stop button, infrared beam, anti-collision

|

|

Architecture

|

integrated framework

|

integrated framework

|

integrated framework

|

integrated framework

|

integrated framework

|

integrated framework

|

integrated framework

|

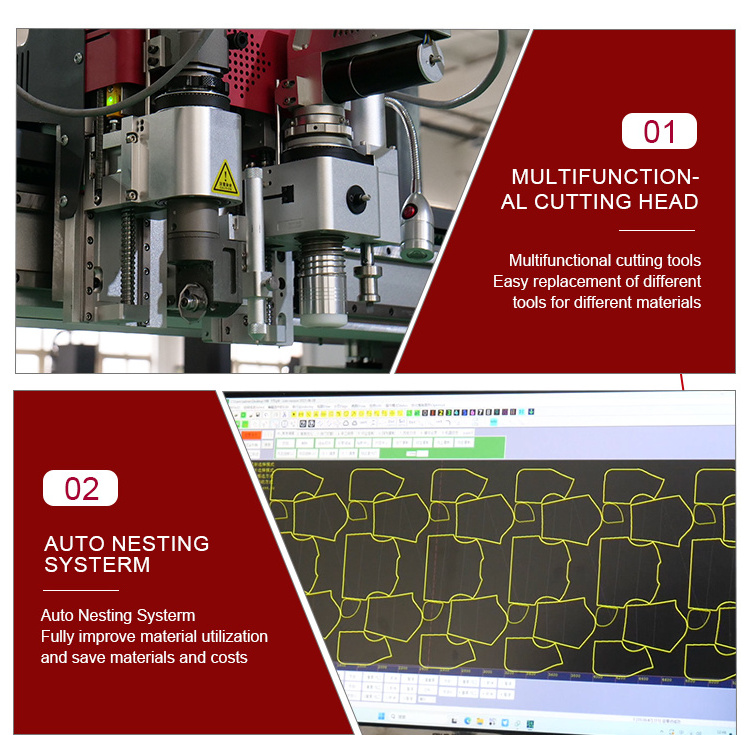

Equipment configuration Vibrating knife cutting, can be configured according to different materials of different cutting heads (round knife, punching, pneumatic knife, punching knife, etc.) loaded with different cutting blades, cutting a variety of flexible materials. Also equipped with a marker pen;

Products Description

General description of the equipment body

The equipment sub-assembly and main core components are divided into the following parts: automatic cutting machine host,automatic typesetting software, electronic control system, vacuum pump, linear guide rail, vibrating cutter head, driver, motor,gear rack, discharge rack, etc.

The equipment sub-assembly and main core components are divided into the following parts: automatic cutting machine host,automatic typesetting software, electronic control system, vacuum pump, linear guide rail, vibrating cutter head, driver, motor,gear rack, discharge rack, etc.

Details Images

Certifications

Application

cnc auto loading oscillating vibrating automatic garment cutting machine digital leather/cloth/fabric/textile knife cutter widely used for cut fabric, leather, cardboard, plastic, paper, rubber, EVA foam, and it can cut many types of foam, such as closed cell foam, rubber foam, foamex, foam core, KT board, EPE foam, polyethylene foam, PE foam, PVC foam, etc. It's widely used for packaging protection, advertising display, termal insulation, model & mock up making, puzzle and pattern cutting, etc.

Product packaging

Why Choose Us

Quality:

Integrated welding frame body,the preferred parts work stable,long service life. Service:

Lifetime after-sales, 24-hour standby service free update software,version and other regular visits.

Secure:

Infrared induction + mechanical collision avoidance system is safer and more assured.

Feature:

Eight kinds of cutter head interchange, meet a variety of materials

cutting,punching.indentation,etc., One machine multi-purpose support multi-cutter head equipment customization.

Precision:

Higher cutting accuracy. The error is within 0.lmm.

Environmental protection:

Cold cutting dust-free, smoke-free,natural environmental protection does not destroy the material

Brain power:

Automatic cutting equipment, automatic plate holding software. Save

materials and eliminate waste.

Integrated welding frame body,the preferred parts work stable,long service life. Service:

Lifetime after-sales, 24-hour standby service free update software,version and other regular visits.

Secure:

Infrared induction + mechanical collision avoidance system is safer and more assured.

Feature:

Eight kinds of cutter head interchange, meet a variety of materials

cutting,punching.indentation,etc., One machine multi-purpose support multi-cutter head equipment customization.

Precision:

Higher cutting accuracy. The error is within 0.lmm.

Environmental protection:

Cold cutting dust-free, smoke-free,natural environmental protection does not destroy the material

Brain power:

Automatic cutting equipment, automatic plate holding software. Save

materials and eliminate waste.

FAQ

Q: 1. How can I choose a suitable cutting machine?A: Please provide us some info, then we can recommend you the suitable machine:

1)What materials are going to cut?

2)What's the largest size of original materials?

3)What's the thickness of materials?

Q: 2. Can you design a machine for me depending on my requirements?

A: Of course, we will discuss details with you and give you our professional suggestion for the machine ensure the machine could match all your requests with best cost performance.

Q: 3. What should I do if the machine has any problem in future?

A: We supply online technical support and door to door service. Anything confuse you, just contact us.

Q: 4. What's the warranty policy?

A:Standard warranty is 12 months upon delivery. Main parts are free of charge(except consumable parts) when problems happened because of quality problem during this period. Problems caused by wrong operate will also well-solved.

Q:5.What is the Price and payment terms?

A:EXW,CIF,FOB we all can accept payment:TT/Paypay/LC/Western Union.etc

Q: 6.What's the package?

A: Film packaging+wooden case. Fumigation-free plywood case is also available

Hot Searches