When our

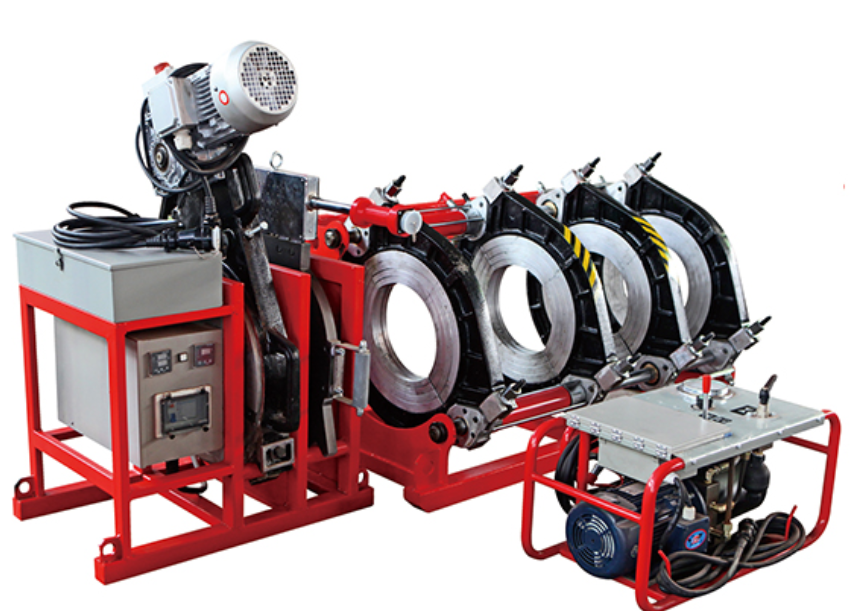

SMD-B630/315H HDPE Welding Machine

welds pipe together with data logger, the welding process is in a semi-automatic way, continuous repeat of the welding cycles and automatic control of preset parameters. Data Logger can store up to 1000 welding cycles and sum them into a encrypted EXCEL file. This report can be transferred to a PC/Laptop through a USB port.

- Product Details

- {{item.text}}

Quick Details

-

Current:

-

20A

-

Dimensions:

-

4.43CBM

-

Use:

-

Butt fusion for plastic pipe and fittings

-

Power (kW):

-

12.35KW

-

Weight (KG):

-

780 KG

-

Application:

-

HDPE PE PPR PVDF welding

-

Welding range:

-

315,355,400,450,500,560,630mm

-

COLOR:

-

Red\Blue\black or as you requested

-

Product Name:

-

Pe Pipe Welding Fusion Machine

-

Output Voltage:

-

380VAC

-

Heating plate Max. Temo:

-

270 ℃

-

Tem.Deviation in Surface (170-250:

-

≤±7 ℃

-

Pressure Adjustable Range:

-

0-8Mpa

-

Working Voltage:

-

380V 50/60HZ

-

Whatsapp:

-

+86-13933031824

-

Certification:

-

CE , ISO , SGS

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZEMOWELD

-

Input Voltage:

-

380V ,50/60HZ

-

Current:

-

20A

-

Dimensions:

-

4.43CBM

-

Use:

-

Butt fusion for plastic pipe and fittings

-

Power (kW):

-

12.35KW

-

Weight (KG):

-

780 KG

-

Application:

-

HDPE PE PPR PVDF welding

-

Welding range:

-

315,355,400,450,500,560,630mm

-

COLOR:

-

Red\Blue\black or as you requested

-

Product Name:

-

Pe Pipe Welding Fusion Machine

-

Output Voltage:

-

380VAC

-

Heating plate Max. Temo:

-

270 ℃

-

Tem.Deviation in Surface (170-250:

-

≤±7 ℃

-

Pressure Adjustable Range:

-

0-8Mpa

-

Working Voltage:

-

380V 50/60HZ

-

Whatsapp:

-

+86-13933031824

-

Certification:

-

CE , ISO , SGS

Products Description

SMD-B630/315H Butt Fusion Welding Machine

is able to weld pipes and fittings with material PE, PP and PVDF, operation easily and suitable for any complex work condition. It Consists of basic frame, hydraulic unit, planing tool, heating plate, support for planing tool& heating plate, and optional parts

Details Images

Frame (Mian boday )

The main body supports and centres the plastic pipes with two fixed and two movable clamps.

Using the hydraulic pressure on the system, the two pistons on the carrying metal bars move the clamps forward and backward and supply the necessary movement for the welding process.

Milling Cutter

The milling cutter is the tool which clean and smooth the both ends of the pipes before the heating process .

Zemoweld butt welding machine is designed for self aligning facer always produces parallel pipe faces.

Zemoweld butt welding machine is designed for self aligning facer always produces parallel pipe faces.

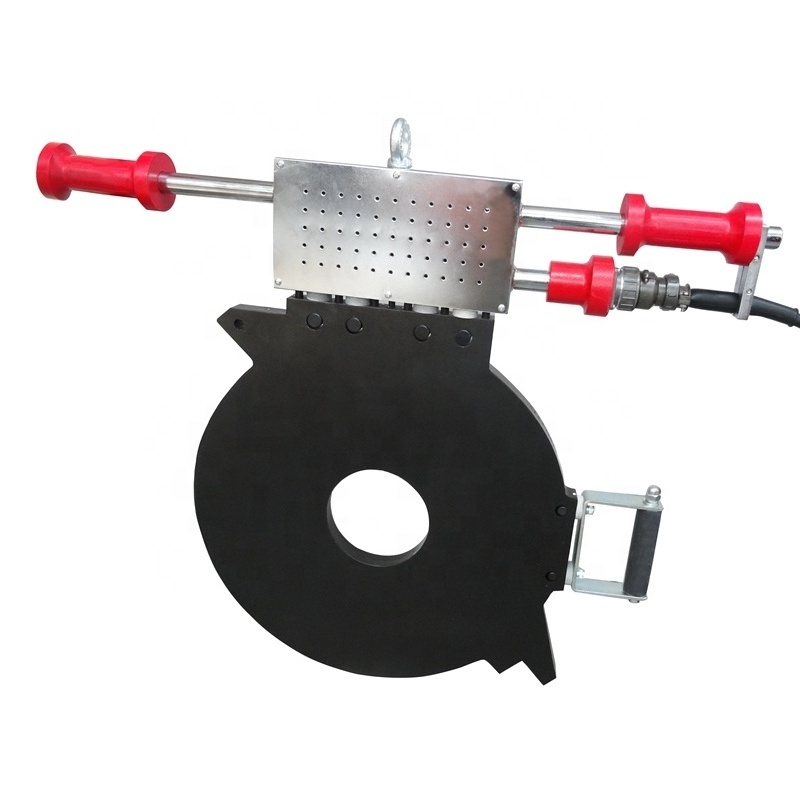

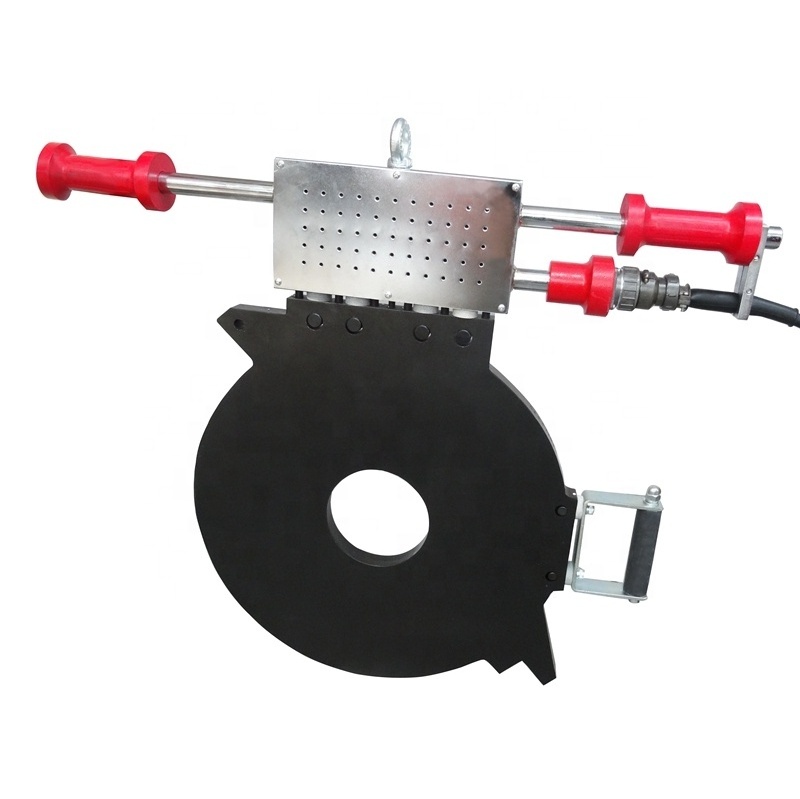

Heater Plate

The pipe ends will be heated by this heater before the welding process. The setting of the heater will be done by the thermostat

on the plates. all butt welding machine PTFE-coated heating element and uniform surface temperature.

Hydraulic Unit

The necessary electric will be transfer to the heater and milling cutter by means of this unit and to the main machine by the hydraulic pressure

Support

The protective casing prevents heat loss of the heater and protects the trimmer from external effects.

Clamps

The clamps will fix the pipe during welding pipe for difference size

Product Paramenters

|

Model

|

|

SMD-B630/315H

|

|

|

Pipe size (mm)

|

|

315,355,400,450,500,560,630mm

|

|

|

Heating plate Max. Temperature

|

|

270℃

|

|

|

Temp.deviation in surface (170-250 ℃)

|

|

≤±7℃

|

|

|

Pressures Adjustable Ranges

|

|

0-8Mpa

|

|

|

Working Voltage

|

|

380V , 50/60HZ , 3P+N+PE

|

|

|

Heating plate power

|

|

9.35KW

|

|

|

Planing tool power

|

|

1.5KW

|

|

|

Hydraulic unit power

|

|

1.5KW

|

|

|

Total Power

|

|

12.35KW

|

|

|

Weight

|

|

780KG

|

|

|

Packing

|

Cases

|

3 plywood cases

|

|

|

|

Volume

|

4.43 CBM

|

|

Product packaging

Hot Searches