- Product Details

- {{item.text}}

Quick Details

-

Usage:

-

Wood planer

-

Voltage:

-

Customizable

-

Dimension(L*W*H):

-

1500*960*875mm

-

Application:

-

Planer, Woodworking, cutting plate saw

-

Weight (KG):

-

290 KG

-

Power (kW):

-

2.2

-

Marketing Type:

-

New Product 2023

-

Product name:

-

300C Combined machine

-

Planer working table:

-

300*1500mm

-

Planer cutterblock diameter:

-

70mm

-

Planer cutterblock rotation speed:

-

5700r.p.m.

-

Planer knives dimensions:

-

300*20*3mm

-

Planer max table adjustement:

-

4mm

-

Max.working height:

-

220mm

-

Min.working height:

-

4mm

-

Max.cutting depth:

-

4mm

-

Weight:

-

290kg

Quick Details

-

Type:

-

Paner

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Joway

-

Usage:

-

Wood planer

-

Voltage:

-

Customizable

-

Dimension(L*W*H):

-

1500*960*875mm

-

Application:

-

Planer, Woodworking, cutting plate saw

-

Weight (KG):

-

290 KG

-

Power (kW):

-

2.2

-

Marketing Type:

-

New Product 2023

-

Product name:

-

300C Combined machine

-

Planer working table:

-

300*1500mm

-

Planer cutterblock diameter:

-

70mm

-

Planer cutterblock rotation speed:

-

5700r.p.m.

-

Planer knives dimensions:

-

300*20*3mm

-

Planer max table adjustement:

-

4mm

-

Max.working height:

-

220mm

-

Min.working height:

-

4mm

-

Max.cutting depth:

-

4mm

-

Weight:

-

290kg

Product Description

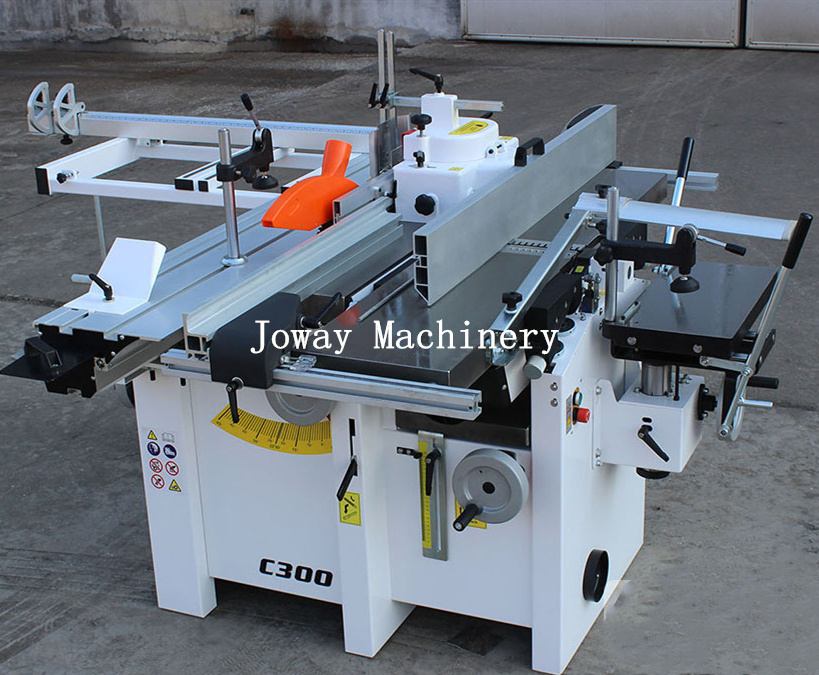

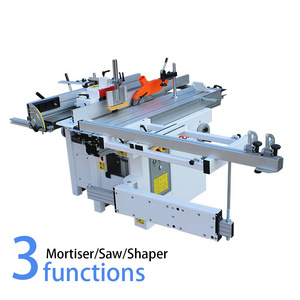

The C300 Combined Machine

The C300 Combined Machine has been specifically designed be an industrial standard machine, but at a size intended for the factory and small professional workshop. This industrially rated machine features a table saw and sliding table, planer, thicknesser and spindle moulder unit. The cast iron construction, accurate cross cut fence and superb build quality put this machine in a class of its own.

Being a professional standard machine, the C300 of course is fully adjustable and the accuracy is second to none. As far as accuracy goes it will not even be bettered by full sized industrial machines. With three independent class 1 motors providing ample power, changing function can be done with the flick of a switch rather than the going through the laborious task of changing belts.

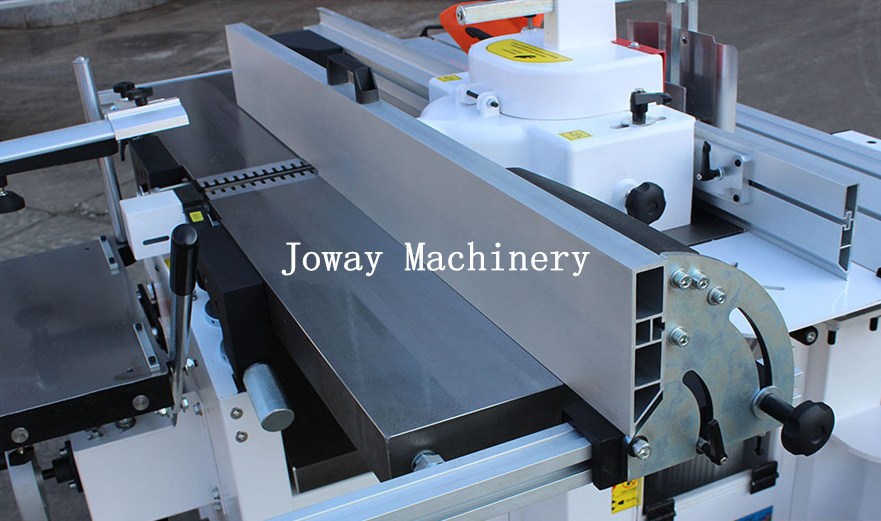

The saw utilises a sliding beam which runs along side the blade like a panel saw. By running the beam this close to the blade,100% accuracy is assured.

The planer thicknessing function, again is of the highest quality, extremely powerful, accurate and the end result is simply sublime. The inward swing of the thicknessing unit keeps this machine compact in every function,whilst the cast iron construction means even heavy pieces can be handled confidently.

Several further options are also available, each machine can therefore be tailored to the users specific needs. These options include; heavy duty morticing unit, spindle moulder ring fence, power feeder and tenoning hood.

Being a professional standard machine, the C300 of course is fully adjustable and the accuracy is second to none. As far as accuracy goes it will not even be bettered by full sized industrial machines. With three independent class 1 motors providing ample power, changing function can be done with the flick of a switch rather than the going through the laborious task of changing belts.

The saw utilises a sliding beam which runs along side the blade like a panel saw. By running the beam this close to the blade,100% accuracy is assured.

The planer thicknessing function, again is of the highest quality, extremely powerful, accurate and the end result is simply sublime. The inward swing of the thicknessing unit keeps this machine compact in every function,whilst the cast iron construction means even heavy pieces can be handled confidently.

Several further options are also available, each machine can therefore be tailored to the users specific needs. These options include; heavy duty morticing unit, spindle moulder ring fence, power feeder and tenoning hood.

Features

|

Panel saw sliding beam

|

Scoring veneered boards

|

Accurate cross cut fence with flipstops

|

|

Cast iron construction

|

Sturdy swinging arm squaring frame

|

Inward parallel swing planer table

|

|

3*2.2kw class 1 motors

|

Micro adjust spindle moulder fence

|

Fully adjustable settings

|

Details Images

Optional Parts

6 sets of milling cutter blades, spiral cutters, and other accessories can be customized according to needs.

Specification

|

Planer

|

Unit

|

300C

|

|

Working tables

|

mm

|

300*1500

|

|

Cutterblock diameter

|

mm

|

70

|

|

Cutterblock rotation speed

|

r.p.m.

|

5700

|

|

N.of knives

|

n

。

|

3

|

|

knives dimensions

|

mm

|

300*20*3

|

|

Max table adjustement

|

mm

|

4

|

|

Thicknesser

|

Unit

|

300C

|

|

Working table

|

mm

|

300*660

|

|

Feed speed

|

m/1'

|

7

|

|

Max.working height

|

mm

|

220

|

|

Min.working height

|

mm

|

4

|

|

Cutterblock rotation speed

|

r.p.m.

|

5700

|

|

Max.cutting depth

|

mm

|

4

|

|

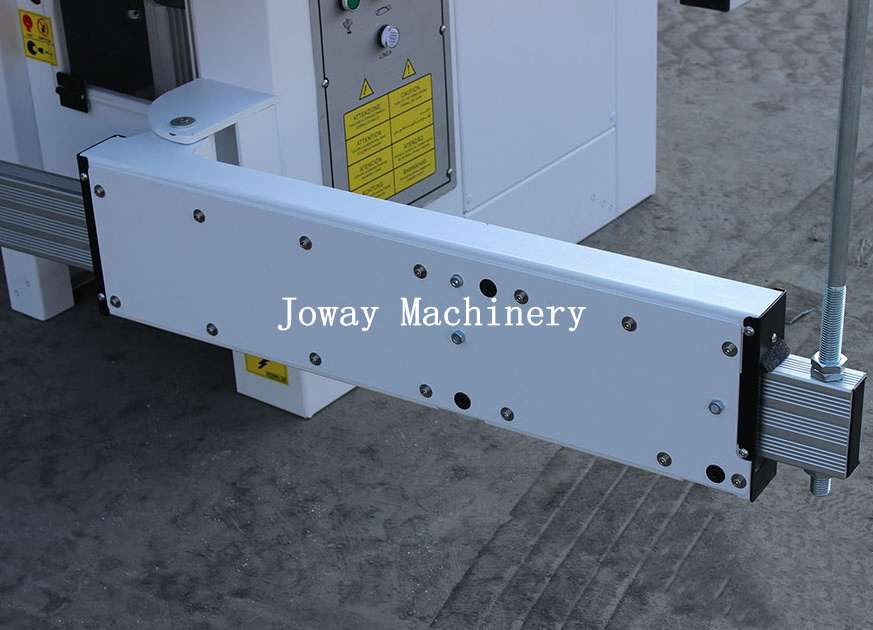

Mortiser

|

Unit

|

300C

|

|

Working table

|

mm

|

250*500

|

|

Longitudinal stroke

|

mm

|

205

|

|

Trasversal stroke

|

mm

|

95

|

|

Vertical stroke

|

mm

|

90

|

|

Churck

|

mm

|

16

|

|

Churck rotation speed

|

r.p.m.

|

5700

|

|

Standard accessories

|

Unit

|

300C

|

|

Service wrenches

|

|

*

|

|

Mortiser chuck

|

|

*

|

|

Guards on mortiseur chuck

|

|

*

|

|

3 pcs.planing knives

|

|

*

|

|

Planer guide

|

|

|

|

Bridge safety hood on planer

|

|

*

|

|

3-phase motor power

|

HP-KW

|

3.0-2.2

|

|

Weight

|

kg

|

290

|

|

Optional accessories

|

Unit

|

300C

|

|

Single-phase motor

|

HP-KW

|

3.0-2.2

|

|

Increasing 3-phase motor

|

HP-KW

|

4.0-3.0

|

|

Wescott(Diameter)

|

mm

|

16

|

Our Advantages

Large and professional factory scale, selling high-quality combination machines.

Packing & Delivery

After the machine is wrapped with wrapping film, it is packaged in standard wooden boxes to ensure the safety of machine transportation.

Recommend Products

Q1: Are you a manufacturer or trading company?

A: We are a manufacturer . We are dedicated to woodworking machinery manufacturing.

Q2: Where is the nearest airport and port from your factory?

A: The nearest port is Qingdao.

Q3: How can I get an accurate price?

Kindly send us the picture of furniture you want to produceand and the working size.

Or detailed machine functions you need, electricity voltage, Hz.

Q4: How is your after sales service?

Our sales are online for 24-hours. We can also supply overseas install service. Also we have more than 10 countries warehouse and department.

Q5: How long is the delivery time?

Generally 7 ~ 15 days.

Q6: Can I get a machine according to my own requirements?

Sure.We accept OEM and ODM

A: We are a manufacturer . We are dedicated to woodworking machinery manufacturing.

Q2: Where is the nearest airport and port from your factory?

A: The nearest port is Qingdao.

Q3: How can I get an accurate price?

Kindly send us the picture of furniture you want to produceand and the working size.

Or detailed machine functions you need, electricity voltage, Hz.

Q4: How is your after sales service?

Our sales are online for 24-hours. We can also supply overseas install service. Also we have more than 10 countries warehouse and department.

Q5: How long is the delivery time?

Generally 7 ~ 15 days.

Q6: Can I get a machine according to my own requirements?

Sure.We accept OEM and ODM

Hot Searches