- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

350

-

Voltage:

-

220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LTPM CHINA

-

Dimension(L*W*H):

-

640*700*1580mm

-

Model:

-

LTWP-320

-

Bag Size Length:

-

60-250mm

-

Bag Size Weight:

-

50-150mm

-

Packaging Speed:

-

40-100/min

-

Power Supply:

-

220V , 50/60Hz

-

power:

-

3.0Kw

-

Pressure:

-

6-8kg/㎡

-

Gas Consumption:

-

0.3m³/min

-

Weight:

-

300kg

-

Size:

-

1400*1000*1200mm

Quick Details

-

Function:

-

FILLING, Wrapping, Labeling, Capping, Sealing, SLITTING

-

Packaging Type:

-

Bags, Pouch, Sachet

-

Packaging Material:

-

Plastic

-

Weight (KG):

-

350

-

Voltage:

-

220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LTPM CHINA

-

Dimension(L*W*H):

-

640*700*1580mm

-

Model:

-

LTWP-320

-

Bag Size Length:

-

60-250mm

-

Bag Size Weight:

-

50-150mm

-

Packaging Speed:

-

40-100/min

-

Power Supply:

-

220V , 50/60Hz

-

power:

-

3.0Kw

-

Pressure:

-

6-8kg/㎡

-

Gas Consumption:

-

0.3m³/min

-

Weight:

-

300kg

-

Size:

-

1400*1000*1200mm

Please Tell Me:

What is your product?

What kind of packaging bag do you want? And more of your request.

We will give you a packaging machine that suits you.

Product introduction

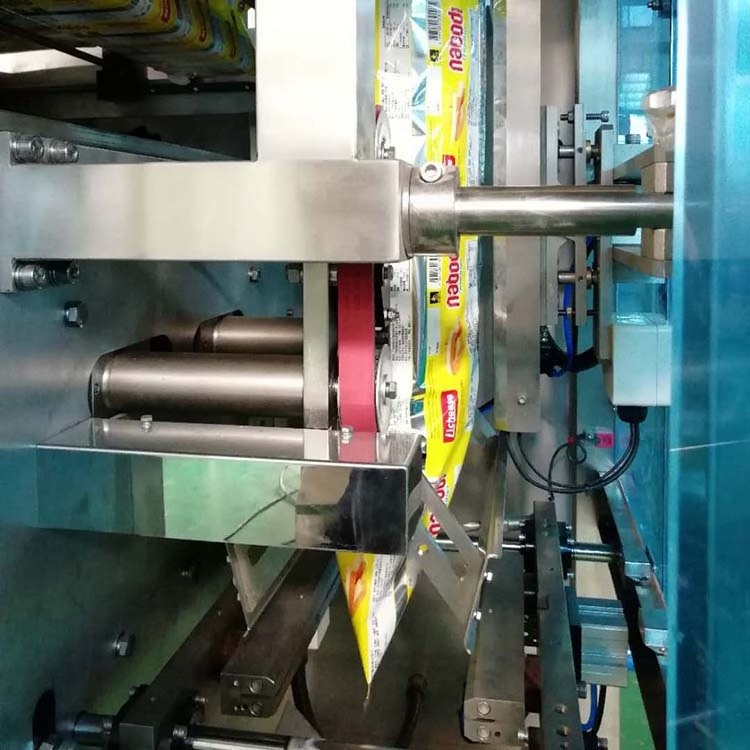

Automatic Vertical Weighing and Packing Machine

The automatic packaging machinery to complete the bag, measuring, filling, nitrogen, play yards, cut bags and so on. Suitable for packaging solid granular materials, such as Potato chips, nuts, chips, candy, puffed food etc.

Packing Range

-- Solid: candy, peanut, green bean, pistachio, brown sugar, cake, daily commodities, cooked food, pickles, puffed food etc.

-- Granule: grain, seed, condiments, granulated sugar, chicken essence, melon seeds, nuts etc.

-- Powder: milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, fertilizer granules etc.

-- Various bag types: all type of side seal bags, e.g. pouch, back-sealing bag, linking bags,etc.

-- Various bag types: all type of side seal bags, e.g. pouch, back-sealing bag, linking bags,etc.

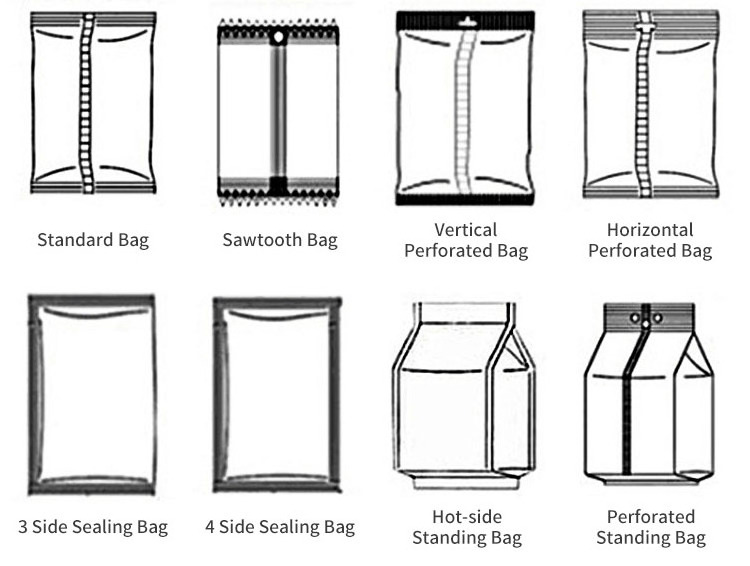

Various bag types:

Standard bag, Sawtooth bag, Vertical perforated bag, Horizontal perforated bag, 3-side sealing bag, 4-side sealing bag, Hot-side standing bag, Perforated standing bag

Applicable packaging film consumables

Suitable for composite film and various colors of aluminized film, non-woven fabric and filter paper

Data

|

Model

|

LTWP-320

|

LTWP-420

|

LTWP-520

|

|

Bag Size Length

|

60-250mm

|

60-300mm

|

80-350mm

|

|

Bag Size Weight

|

50-150mm

|

60-200mm

|

80-250mm

|

|

Packaging Speed

|

40-100/min

|

35-80/min

|

30-80/min

|

|

Power Supply

|

220V , 50/60Hz

|

220V , 50/60Hz

|

220V , 50/60Hz

|

|

power

|

3.0Kw

|

3.0Kw

|

4.0Kw

|

|

Pressure

|

6-8kg/㎡

|

6-8kg/㎡

|

6-8kg/㎡

|

|

Gas Consumption

|

0.3m³/min

|

0.3m³/min

|

0.3m³/min

|

|

Weight

|

300kg

|

350kg

|

350kg

|

|

Size

|

1400*1000*1200mm

|

1650*1100*1500mm

|

1650*1200*1600mm

|

|

Model

|

LTWP-620

|

LTWP-820

|

LTWP-1250

|

|

Bag Size Length

|

100-400mm

|

120-500mm

|

150-800mm

|

|

Bag Size Weight

|

100-300mm

|

120-400mm

|

150-600mm

|

|

Packaging Speed

|

30-70/min

|

20-60/min

|

5-30/min

|

|

Power Supply

|

220V , 50/60Hz

|

220V , 50/60Hz

|

220V , 50/60Hz

|

|

power

|

4.0Kw

|

4.0Kw

|

4.0Kw

|

|

Pressure

|

6-8kg/㎡

|

6-8kg/㎡

|

6-8kg/㎡

|

|

Gas Consumption

|

0.3m³/min

|

0.3m³/min

|

0.3m³/min

|

|

Weight

|

400kg

|

450kg

|

500kg

|

|

Size

|

1800*1300*1750mm

|

2050*1600*2050mm

|

2128*2057*2385mm

|

Product Details

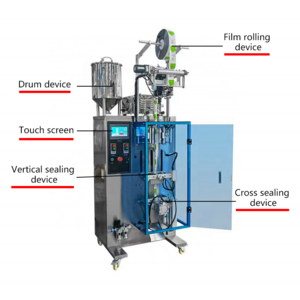

Touch Screen

Smart touch screen control system Various parameters are displayed directly on the screen

Double Stretch Film Mechanism, Lapel Bag Making

Stable operation, not easy to run sideways, making bags more beautiful Former can be replaced according to bag size

Heat Sealing Mode

Sealing tightly and beautifully Suitable for a variety of membrane materials Sponge exhaust, flat packing

Roll Film Bag

Easy to replace and easy to operate

Neatly Arranged

Each piece is clearly marked with a serial number for easy search

Ribbon Coding Machine

Standard configuration, print production date Clear handwriting, environmental protection guard

Features

1.New design, beautiful appearance, more reasonable structure, more advanced technology;

2.The production line supporting machinery in addition to marked materials are stainless steel, all machine structures are in accordance with food hygiene standards selected design;

3.Often dismantling the structure are easy to dismantle the connection, to ensure that the shift or change the product when dealing with health convenience;

4.Multiple automatic alarm protection functions to minimize damage;

5.Touch screen and stable and reliable PLC control, bag-making, metering, filling, sealing, coding, bag-cutting one-time

completion;

5.Touch screen and stable and reliable PLC control, bag-making, metering, filling, sealing, coding, bag-cutting one-time

completion;

6.External film release mechanism is adopted to facilitate the installation of packaging film.

Hot Searches