- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CBN Inserts

-

Application:

-

Internal External Turning Inserts

-

Product name:

-

PCD Insert

-

MOQ:

-

10pcs

-

OEM:

-

OEM Welcomed

-

Sample:

-

Sample Provided

-

Feature:

-

High Efficiency

-

PAYMENT:

-

T/T 100%/ Paypal

-

Brand:

-

SAISU

-

Workpiece:

-

Steel\ Stainless\ Cast Iron\Aluminium

Quick Details

-

Type:

-

Abrasive Disc

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SAISU

-

Model Number:

-

CBN Inserts

-

Application:

-

Internal External Turning Inserts

-

Product name:

-

PCD Insert

-

MOQ:

-

10pcs

-

OEM:

-

OEM Welcomed

-

Sample:

-

Sample Provided

-

Feature:

-

High Efficiency

-

PAYMENT:

-

T/T 100%/ Paypal

-

Brand:

-

SAISU

-

Workpiece:

-

Steel\ Stainless\ Cast Iron\Aluminium

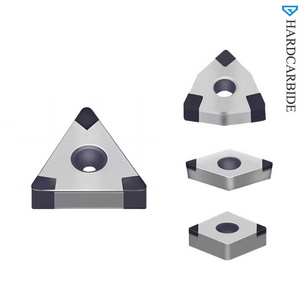

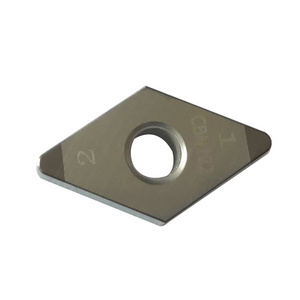

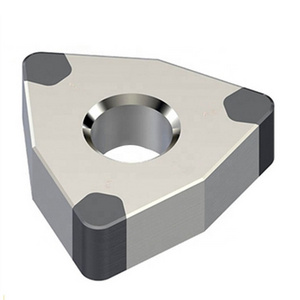

PCD CBN PCBN Insert for Resurfacing Auto Engine Cylinder Casing Heads RNGN120400A CNC Lathe Machine Cutter Insert

The key to achieving high quality ultra-smooth surface finishes is using the right equipment, the right abrasives and the right resurfacing techniques

1. Processed workpiece:

hardness steel, gray cast iron, high hardness cast iron, powder metallurgy and

thermal spray coated workpiece, others (Co>15%wt Carbide HRA=80-88), etc.

2. Work efficiency: improved by 5-10 times when compared to grinding

thermal spray coated workpiece, others (Co>15%wt Carbide HRA=80-88), etc.

2. Work efficiency: improved by 5-10 times when compared to grinding

Products Description

Cubid Boron Nitride CBN cutter

CBN, an ultra-hard cutting material consisting of polycrystalline cubic boron nitride with a metallic or ceramic binder is primarily used to machine hardened ferrous material. Its available either as a tip brazed to a carbide insert carrier or as a solid insert. CBN cutters can be double-sided grinding and have a longer service life. If youre using a solid CBN tip, after one side is worn out you simply flip it over and use it again.

CBN, an ultra-hard cutting material consisting of polycrystalline cubic boron nitride with a metallic or ceramic binder is primarily used to machine hardened ferrous material. Its available either as a tip brazed to a carbide insert carrier or as a solid insert. CBN cutters can be double-sided grinding and have a longer service life. If youre using a solid CBN tip, after one side is worn out you simply flip it over and use it again.

Poly Crystalline Diamond PCD cutter with carbide support

PCD (Polycrystalline Diamond) is an ultra-hard tool material (substrate) consisting of a synthetic polycrystalline diamond tip

brazed to a carbide insert carrier. Primarily used to machine non-ferrous materials at high speeds, PCD has been developed

specifically to machine aluminum. CBN only smears the aluminum when removing metal without producing the necessary finish todays aluminum heads require. To extend the life of your tooling, use adequate lubrication.

PCD (Polycrystalline Diamond) is an ultra-hard tool material (substrate) consisting of a synthetic polycrystalline diamond tip

brazed to a carbide insert carrier. Primarily used to machine non-ferrous materials at high speeds, PCD has been developed

specifically to machine aluminum. CBN only smears the aluminum when removing metal without producing the necessary finish todays aluminum heads require. To extend the life of your tooling, use adequate lubrication.

For Advantage of our PCD CBN cutter

1) Hight Abrasion resistant/High impact resistance

2)Easy to replace inserts.

3)All the cutting tools quality meet the ISO international standard.

4)Use orginal tungsten carbide material as basement.Using content of 99.95% or more high purity raw material, to ensure performance of PCD inserts basement.

5)Using box and carton packing, convenient for customer to handling.

2)Easy to replace inserts.

3)All the cutting tools quality meet the ISO international standard.

4)Use orginal tungsten carbide material as basement.Using content of 99.95% or more high purity raw material, to ensure performance of PCD inserts basement.

5)Using box and carton packing, convenient for customer to handling.

Most of today's high speed surfacers are designed to use CBN or PCD inserts in their cutter heads. CBN is the most popular choice for cutting both cast iron and aluminum because it can handle either material with ease. CBN also cuts cleanly at high rpm and can take the heat that's generated by higher cutting speeds. PCD Inserts are still the best choice for resurfacing aluminum. Because of the unique metallurgy of aluminum and the chemical interaction present with heat, CBN does not give the appropriate surface finish that PCD can provide.PCD Inserts consist of a layer of Polycrystalline Diamond bonded to a carbide substrate. As an added benefit, the carbide back can be used for aluminum heads after PCD side is used up.Carbide is still popular because of its lower initial cost, and coated carbide helps extend tool life.

Our Advantages

√ Excellent cost performance

The service life of PCD PCBN insert can be more than 10 times that of carbide insert and reduce the cost of comprehensive cutting tool by 30%-50%. The interval time between the replacements of PCD PCBN insert is long and the insert replacement frequency is less, which can significantly reduce the cost on inserts.

√ High machining efficiency

The machining efficiency of PCD PCBN insert is 5-10 times that of the carbide insert, which greatly improves the equipment capacity and reduces the fixed investment of equipment.

√ Excellent surface quality

Surface finish and dimensional precision of machining workpiece of PCD PCBN insert can reach the grinding level, and make turning instead of grinding to reduce equipment investment.

√ Strong universality

PCD PCBN insert can be used for both dry cutting and wet cutting and one grade normally is suitable for machining a variety of materials.

The service life of PCD PCBN insert can be more than 10 times that of carbide insert and reduce the cost of comprehensive cutting tool by 30%-50%. The interval time between the replacements of PCD PCBN insert is long and the insert replacement frequency is less, which can significantly reduce the cost on inserts.

√ High machining efficiency

The machining efficiency of PCD PCBN insert is 5-10 times that of the carbide insert, which greatly improves the equipment capacity and reduces the fixed investment of equipment.

√ Excellent surface quality

Surface finish and dimensional precision of machining workpiece of PCD PCBN insert can reach the grinding level, and make turning instead of grinding to reduce equipment investment.

√ Strong universality

PCD PCBN insert can be used for both dry cutting and wet cutting and one grade normally is suitable for machining a variety of materials.

Application

For turning and milling of cylinder blocks and heads, centrifugal rolls, slurry pumps, brake discs, brake drums, rolling mortar walls, compressor parts, gears, bearings, mining machinery, coal mining machinery industries.

Customer Reviews

Why Choose Us

Team

Professional team to give you an excellent shopping experience 1 to 1

professional service

professional design

docking First line workers

SERVICE

Sample and good after-sales service one year warr-anty Reply message timely Short delivery cycle

professional export experience

FACTORY

We have rich experience in the production of diamond products, including various diamond dressers,

grinding wheels and many grinding products etc

OEM&ODM

Products can be customized according to your requ-irements.Customized drawings free of

charge ;

Free logo design;Free packaging design;Design customi-zed products; free design drawing

Professional team to give you an excellent shopping experience 1 to 1

professional service

professional design

docking First line workers

SERVICE

Sample and good after-sales service one year warr-anty Reply message timely Short delivery cycle

professional export experience

FACTORY

We have rich experience in the production of diamond products, including various diamond dressers,

grinding wheels and many grinding products etc

OEM&ODM

Products can be customized according to your requ-irements.Customized drawings free of

charge ;

Free logo design;Free packaging design;Design customi-zed products; free design drawing

Hot Searches