- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Color:

-

as your requirement

-

Material thickness:

-

1.2 mm

-

Forming stations:

-

28-30 stations (according the final design)

-

Control system:

-

PLC(Touch Screen)

-

Advantages:

-

High Efficent

-

Certification:

-

ISO9001

-

Roller material:

-

GCR12 Bearing Steel

-

Service:

-

1 Year Guarantee

Quick Details

-

Core Components:

-

PLC

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BN

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Color:

-

as your requirement

-

Material thickness:

-

1.2 mm

-

Forming stations:

-

28-30 stations (according the final design)

-

Control system:

-

PLC(Touch Screen)

-

Advantages:

-

High Efficent

-

Certification:

-

ISO9001

-

Roller material:

-

GCR12 Bearing Steel

-

Service:

-

1 Year Guarantee

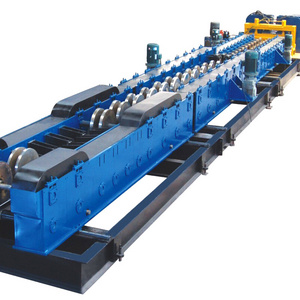

Main Features

1.machine adopt advanced technicall

2.high quality of the structure

3,one year warranty

4.more the 10 years experience

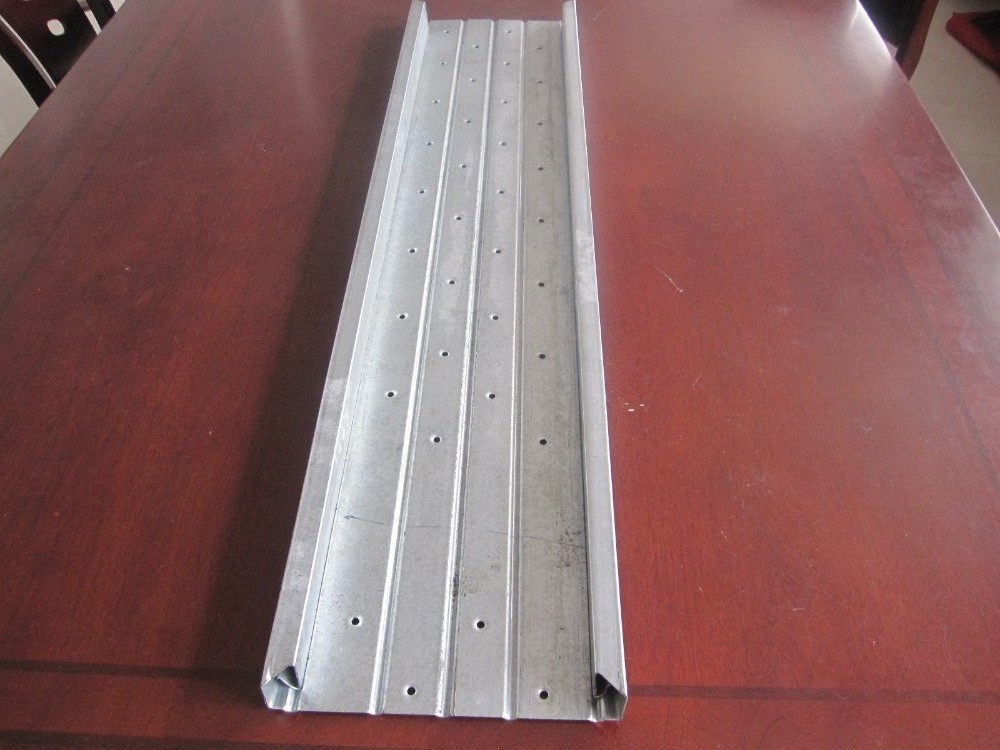

profile

Roll Forming Machine:YX38-240

Material width :490mm G.I

Rolling Speed :5-6m/min(not include cutting time)

Rolling Thickness :1.2mm

Control System: PLC (Panasonic) as list in the note

Un Coiler :5 ton hydraulic un-coiler

Leveling Station :1 station (7 rollers)

Leveling Power: 5.5KW

Feeding system: servo feeding

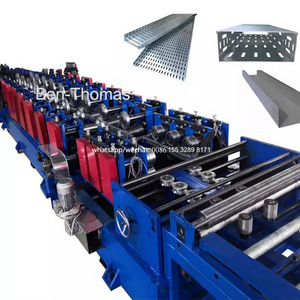

Punching Machine: 1 punching machine 80Ton

Punching Model: 1 set

Pre-punching system :1 station on the roll forming machine (Punching the gap)

Roller Stations :About 28-30 stations

Main Motor power :22KW (two 11KW)

Roller Material :GCR15, coated with chrome

Shaft Material and DIA: ¢85mm, material is 45# forge steel,hardening and tempering

Way Of Drive : 1.5 inch single chain

Cutting system :Hydraulic Cutting

Hydraulic Station Power : 5.5kw

Hydraulic Pressure :10-12Mpa

Type Of The Stations : Wall panel

Tolerance :3m±1.5mm

Electric Source :380V, 50HZ,3 phase Also can satisfy customer’s require

Color Of The Machine :Yellow and blue

Size Of The Machine : L*W*H 8m*1m*1.7m

Container Need :1 x 40 feet and 1 x 20 feet

No paking, directly fix the machine to the container with belt and wood.

1.1 year and life-long maintenance;

2.Installation and debugging:We will send professional engineer to make installation and debugging,buyer pay our engineer eachi one 50USD/day,and provide accommodation ,food and the round-trip ticket fee;

3.Installation Days:about 5-7 days

Our machine is definitely guarantee for 12 months. If there is any problem,we will send the technician to fix the problem ASAP!

Our main products include roll forming machines, guardrail roll forming machines, steel deck forming machines, door & window frame roll forming equipment, steel metal door making lines, guide rail rollforming machines, upright post roll formers, pipe and tube roll formers, purlin cold roll forming machines, T-bar forming machines, grape trellis roll forming machines, roof tile forming machines, steel metal panel roll forming machines, stud and track forming machines, cable tray roll forming machines, shelf rack making machines, gutter roll forming machines, roller shutter manufacturing lines, car bumper forming machines, car door forming machines, distribution cabinet making machines, channel roll forming machines and so on.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate