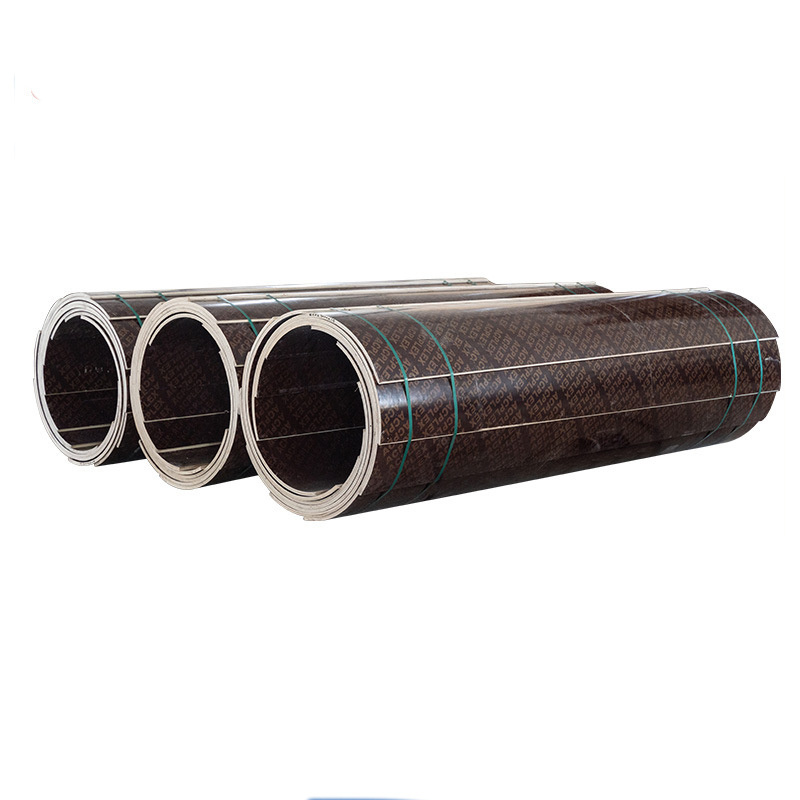

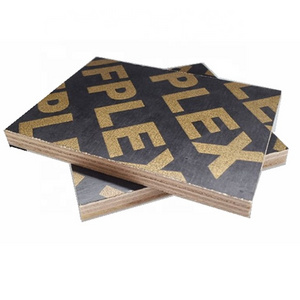

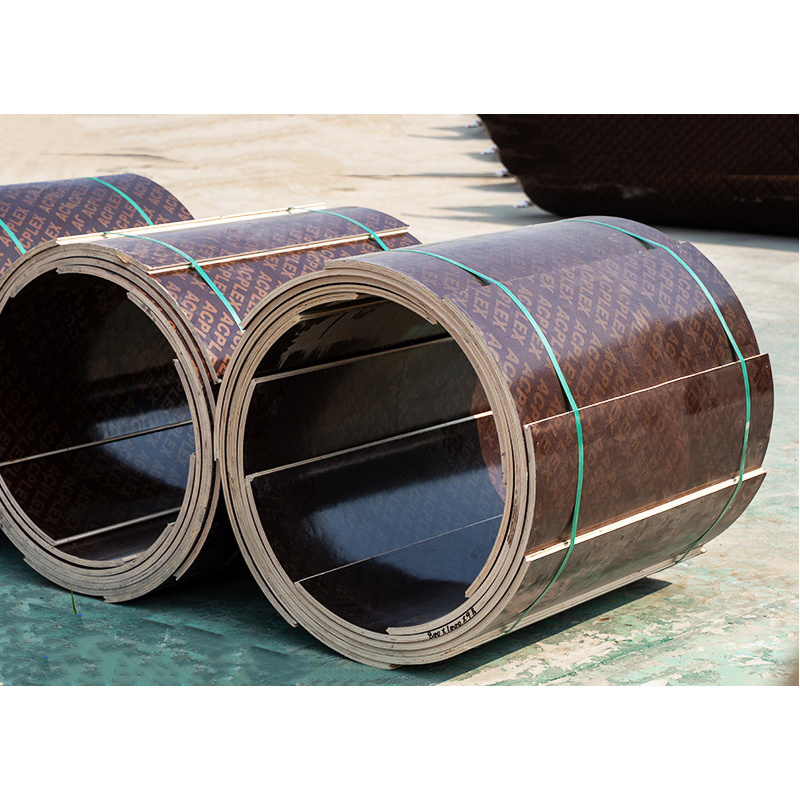

Our company's round template adopts birch poplar wood as the base material, after single-sided hot pressing, double-sided overmolding, the texture of the template is strong and durable, compared to other similar products of other companies, the number of turnovers, strong pressure-bearing capacity, pouring does not run slurry, does not burst the mold, and the concrete cylinder can be formed with clean water after demolding.

- Product Details

- {{item.text}}

Quick Details

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

pengxiang

-

Model Number:

-

Cylindrical wood formwork

-

Product name:

-

Cylindrical wood formwork

-

Whether the template is customized:

-

Support for customization

-

veneer surface material:

-

pine

-

Face/back:

-

Pine

-

Core:

-

Poplar,Pine ,Hardwood, Combi,Eucalyptus

-

Glue:

-

MR/E0/E1/E2/WBP/Melamine/Phenolic

-

Item Application:

-

structural ,Ceiling ,Building ,Construction or others

-

Moisture:

-

8%-14%

-

Thickness:

-

14~22mm

-

Inner wall diameter:

-

100--3000mm

Quick Details

-

Warranty:

-

1 Year

-

Project Solution Capability:

-

NONE

-

Application:

-

Hotel

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

pengxiang

-

Model Number:

-

Cylindrical wood formwork

-

Product name:

-

Cylindrical wood formwork

-

Whether the template is customized:

-

Support for customization

-

veneer surface material:

-

pine

-

Face/back:

-

Pine

-

Core:

-

Poplar,Pine ,Hardwood, Combi,Eucalyptus

-

Glue:

-

MR/E0/E1/E2/WBP/Melamine/Phenolic

-

Item Application:

-

structural ,Ceiling ,Building ,Construction or others

-

Moisture:

-

8%-14%

-

Thickness:

-

14~22mm

-

Inner wall diameter:

-

100--3000mm

Product Paramenters

|

|

|

|

||||

|

INNER DIAMETER SIZE(MM)

|

PLATE THICKNESS(MM)

|

LENGTH(MM)

|

NUMBER OF SPLICES

|

|||

|

250——550

|

15±1

|

3000

|

2

|

|||

|

600——1200

|

18±1

|

3000

|

2

|

|||

|

1250——1500

|

22±0.5

|

3000

|

2

|

|||

|

1600——4200

|

22±0.5

|

2400

|

4~10

|

|||

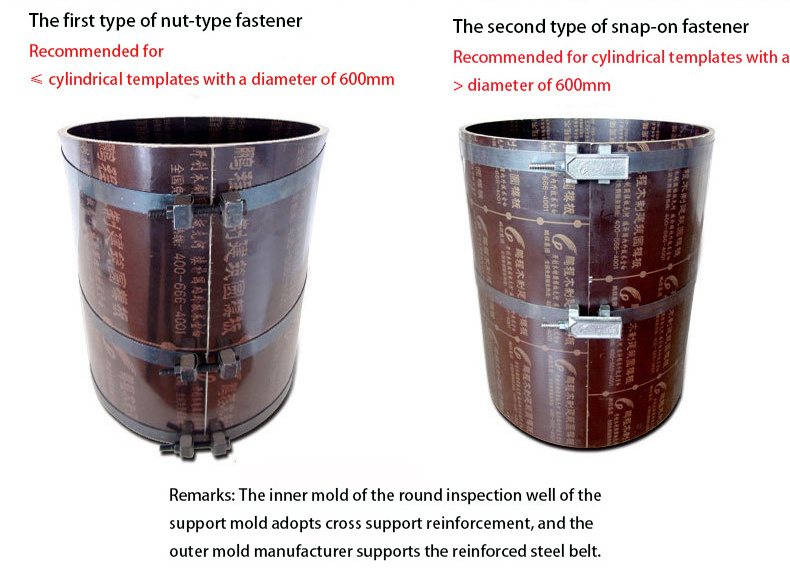

Concave and convex connector

Bevel cuts(Internal mold)

The Number Of Turnovers Is Large, And The Template Is Under Strong Pressure

Compared With Steel Formwork, Cylindrical Wood Templates Are More Convenient

Construction units often encounter points that need to be lapped, such as top beams and columns during the construction process,especially in the case of bridges, temples and other columns, complex structures, steel molds and other their own limitations cannot be cut arbitrarily, often given The actual construction caused great difficulties. With its good structural performance, thesquare circle formwork can be cut arbitrarily according to the actual size, which plays a great role in reducing the constructiondifficulty and shortening the construction period for the construction party.

Less weight

The wooden building formwork is made of birch poplar as raw material, which is characterized by light weight than ordinary poplar, and high strength and good toughness.

Less cost

The price of cylindrical formwork is better than that of steel formwork, generally from the source, it is about one-third of the price of steel formwork. It saves builders a lot of costs. The construction is convenient and fast, no tower crane equipment is required, and it can be operated in batches, which is invisibly used to shorten the construction period of the project.

Due to the light weight of wooden building formwork, it consists of 2-3 Individual workers can manually install and disassemble in batches Unloading, does not occupy tower crane equipment, one group (2-3 people)Workers can install 10-16 trees in eight hours.

Solve The Mold Release Challenge

In the problem of demolding, the steel mold is difficult to demold, generally used 3 times to trim, the concave and convex surface increases a lot of artificial material resources. However, the effect of PVC template and strip template after shaping and demolding is not satisfactory. The round template can

be used for many times to reach 6-8 times, the demolding is simple and easy to operate, the concave and convex groove design makes the slurry natural, and the effect after demolding is very good.

The cylinder body is smooth and well formed

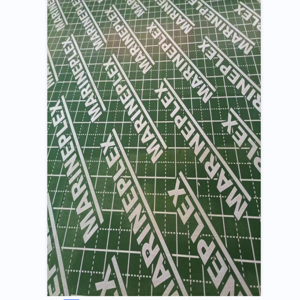

It is made from large-clad plywood There are fewer joints and seams, and the quality of the birch wood ensures the formwork,The high strength and toughness, the inner and outer epoxy resin laminate is not But smooth and waterproof and has a certain degree of breathability, hit,The concrete cylinder is not only smooth but also well-shaped.The look and feel are very good, and the overall effect is better than similar ones He product, belongs to the clear water

formwork

.

Use effect display

Hot Searches