- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

5050*2300*2430mm

-

Weight:

-

4000 KG

-

Model:

-

YG -YS850

-

Max. Printing material width:

-

850mm

-

Max. Printing width:

-

850mm

-

Max. Unwinding diameter:

-

1200mm

-

Max. Rewinding diameter:

-

1200mm

-

Printing length range:

-

230-1000mm

-

Printing speed:

-

50m-80m min

-

Register precision:

-

≤±0.15mm

-

Thickness of plate:

-

2.28mm+0.38mm

-

Total Power:

-

35KW

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yugong

-

Voltage:

-

380V

-

Dimensions(L*W*H):

-

5050*2300*2430mm

-

Weight:

-

4000 KG

-

Model:

-

YG -YS850

-

Max. Printing material width:

-

850mm

-

Max. Printing width:

-

850mm

-

Max. Unwinding diameter:

-

1200mm

-

Max. Rewinding diameter:

-

1200mm

-

Printing length range:

-

230-1000mm

-

Printing speed:

-

50m-80m min

-

Register precision:

-

≤±0.15mm

-

Thickness of plate:

-

2.28mm+0.38mm

-

Total Power:

-

35KW

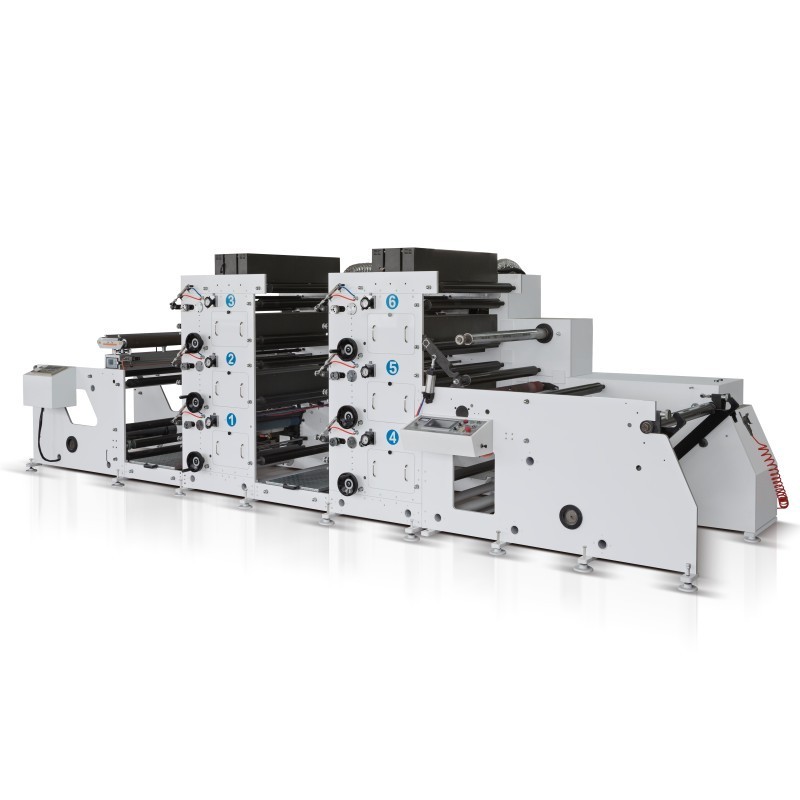

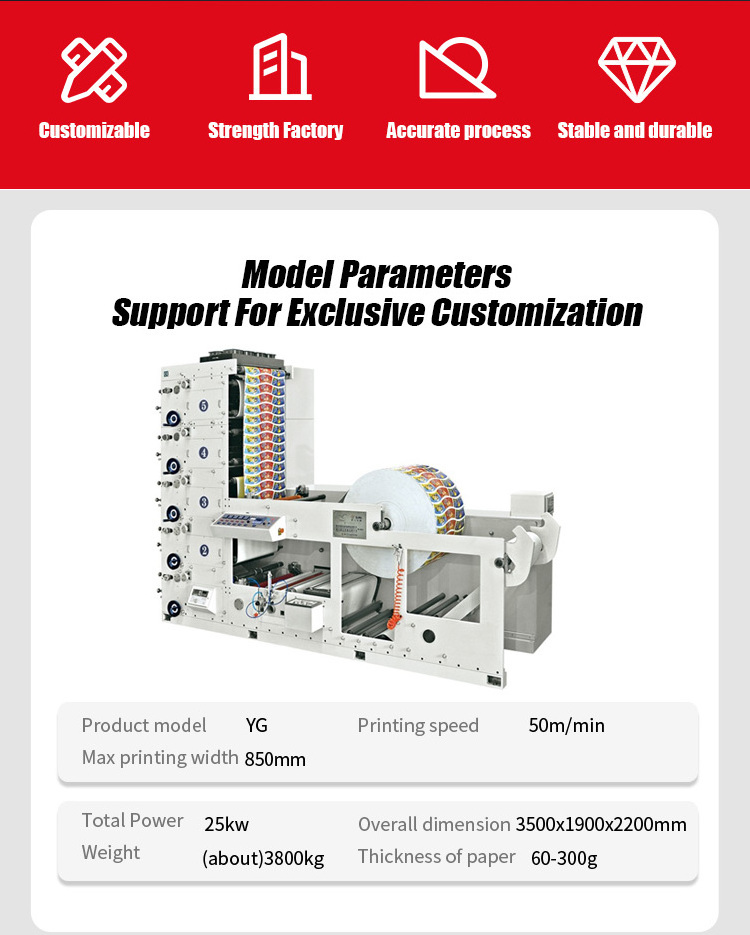

Smoke Rolling Poster Paper Money Printing Machine Poker Paper Printing Machine

| 4-color wide-format printing machine | |||

| Model | YG -YS850 | ||

| Printing speed | 50m-80m/min | ||

| Printing width | 850mm | ||

| Feed width | 860mm | ||

| Unwinding diameter | 1200mm | ||

| Rewinding diameter | 1200mm | ||

| Printing size | 175-380mm | ||

| Overprint accuracy | ±0. 15mm | ||

| Voltage | 380V | ||

| Total power | 35KW | ||

| Total pressure | 0. 6MP | ||

| Weight | 3500kg | ||

| Dimensions | 3050*2300*2430mm 2250*1900*1450mm | ||

Automatic web die-cutting machine based on international advanced technology, has a high stability, high safety performance, high precision of the finished product, it’s widely used in printing, packaging and paper products industries. It adopts micro-computer, human-computer control interface, servo positioning, alternating current frequency converter, automatic counting, manual pneumatic lock plate, photoelectric correcting deviation system, electromagnetic cluth, centralized oil lubrication, overload protection and distinctive gearing. So it guarantees smooth operations of returning paper and feeding paper, precise positioning and orderly withdrawing. All the key parts and controls of the machine are imported. Such installation can realize the machine in steady pressure, precise positioning, smooth moving, safety and reliability.

Paper Die Cutting Machine Feature 1. It adopts German technology and movement worm gear and worm structure to synchronously send oil to all parts of the movement to prolong the service life of the equipment. 2. Adopt typesetting technology to save sector paper by 18%, save labor cost and manufacturing cost, and improve production efficiency. 3. Control feeding, realize color code tracking and die cutting. 4. According to the paper layout, different shapes of knife plate can be used, and the knife plate can be pneumatically locked, which is convenient to replace. 5. The paper feeding double row cots move randomly and synchronously, and the air assisted paper feeding improves the paper feeding function. 6. Roll embossing belt die cutting, indentation and tile, one machine for multiple purposes.

Packaging:

General export packing or customized packaging according to your requirement.

Shipping:

Professional goods shipping forwarders.

Delivery Time:

20-30working days after deposit.