- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Product Name:

-

SYJ-400 Dicing / Cutting Saw

-

Power supply voltage:

-

110V/220V

-

Spindle drive power:

-

180W

-

Spindle speed:

-

0-3000rpm

-

X-axis sliding plate stroke:

-

210mm

-

Y-axis sliding plate stroke:

-

110mm

-

Z-axis sliding plate stroke:

-

90mm

-

Stepper motor resolution:

-

0.0025mm

-

Stepper motor positioning accuracy:

-

0.01mm

-

Maximum cutting depth:

-

50mm

Quick Details

-

Warranty:

-

one year

-

Brand Name:

-

MTI

-

Model Number:

-

SYJ-400

-

Place of Origin:

-

Henan, China

-

Product Name:

-

SYJ-400 Dicing / Cutting Saw

-

Power supply voltage:

-

110V/220V

-

Spindle drive power:

-

180W

-

Spindle speed:

-

0-3000rpm

-

X-axis sliding plate stroke:

-

210mm

-

Y-axis sliding plate stroke:

-

110mm

-

Z-axis sliding plate stroke:

-

90mm

-

Stepper motor resolution:

-

0.0025mm

-

Stepper motor positioning accuracy:

-

0.01mm

-

Maximum cutting depth:

-

50mm

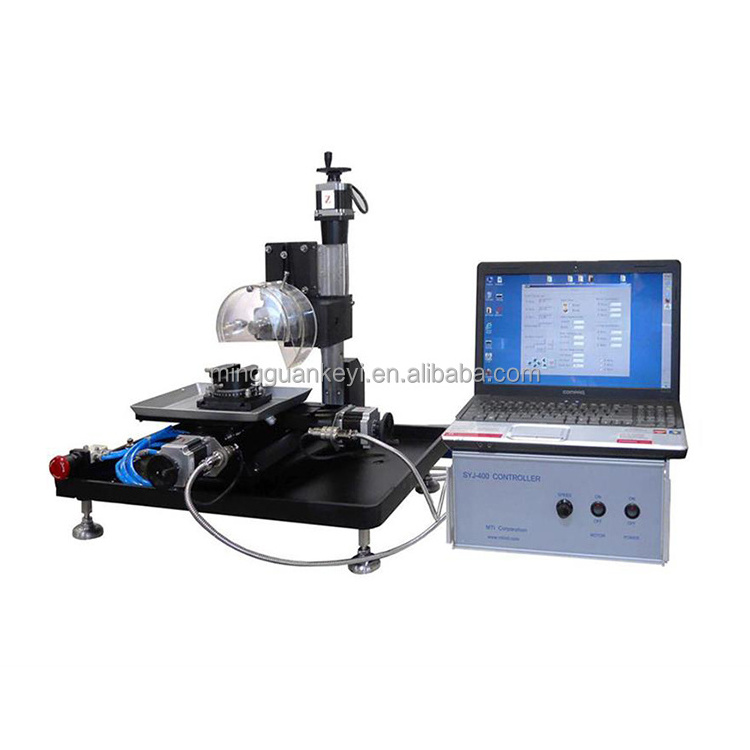

Precision CNC Dicing / Cutting Saw with Complete Accessories - SYJ-400

CNC cutting machine - SYJ-400

Product Introduction:

SYJ-400 CNC slicing and cutting machine is a CE certified cutting machine mainly suitable for slicing, grooving, and cutting various materials such as crystals, ceramics, glass, ores, metals, etc. The motor of this machine adopts a stepper motor, with a positioning accuracy of 0.01mm. The sample workbench can rotate 360 ° and is equipped with a cross clamp (90 ° positioning mold ensures the accuracy of cutting right angles). It is one of the ideal precision cutting equipment for laboratories and production units. The SYJ-400 CNC cutting machine is a continuous cutting equipment that can set up a cutting program to continuously slice or groove the sample. The spindle speed is infinitely adjustable, the cutting speed is fast, the operation is stable, and the cutting path is precise. During the working process, it can be cooled by external circulating water to cool the cut sample. Different cutting saw blades can be selected depending on the material of the cut sample. The SYJ-400 CNC cutting machine has a small volume and low noise during operation. The sample cutting table is equipped with a waterproof cover to prevent splashing of water. This machine can be controlled by a computer (with MTI operation software) or a microcontroller, allowing for self programming to cut samples.

Main features:

·Computers can be used for control, allowing for self programming and cutting.

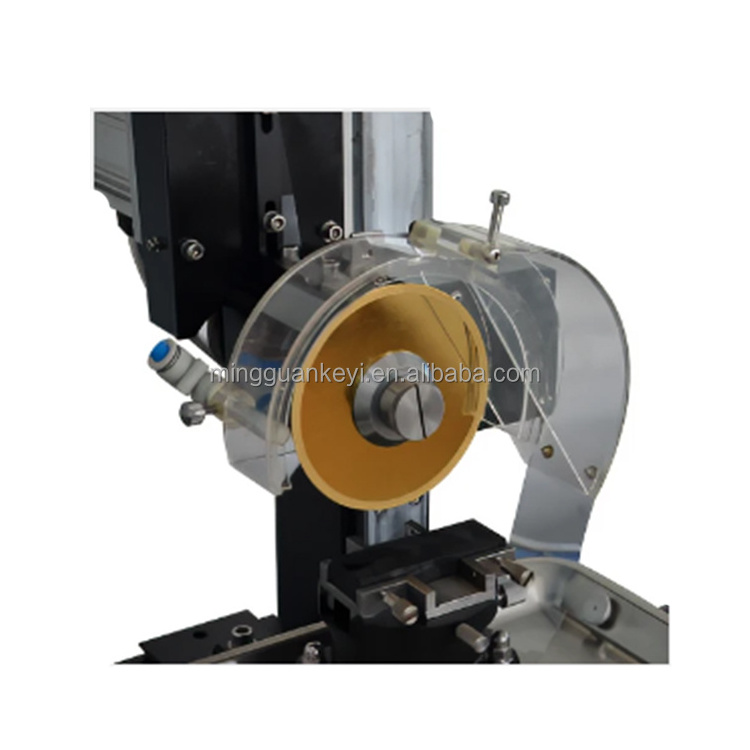

·Adopting a high torque AC brushless motor, the main shaft is driven to rotate through a pulley group. By controlling the speed control knob, the speed can be adjusted between 300rpm and 3000rpm.

·Suitable saw blades and saw pads can be selected based on the size of the material.

·Equipped with a waterproof cover and capable of controlling coolant flow through a throttle valve.

Technical parameters:

|

Product Name |

SYJ-400 Dicing / Cutting Saw |

|

Product model |

SYJ-400 |

|

Installation conditions |

This equipment is required to be used below an altitude of 1000m, at a temperature of 25 ℃± 15 ℃, and at a humidity of 55% Rh ± 10% Rh. 1. Water: The equipment is equipped with water inlet and outlet, and needs to be connected to tap water and drainage by oneself 2. Electricity: AC220V 50Hz, must have good grounding 3. Gas: None 4. Workbench: size 800mm × 600mm × 700mm, with a load-bearing capacity of over 50kg 5. Ventilation device: required |

|

Main parameter |

1. Power supply voltage: 110V/220V 2. Spindle drive power: 180W 3. Spindle speed: 0-3000rpm 4. X-axis sliding plate stroke: 210mm 5. Y-axis sliding plate stroke: 110mm 6. Z-axis sliding plate stroke: 90mm 7. Stepper motor resolution: 0.0025mm 8. Stepper motor positioning accuracy: 0.01mm 9. Maximum cutting depth: 50mm 10. Workbench rotation: 360 ° ± 0.5 ° 11. Load plate: 80mm × 25.4mm 12. Saw blade: Ø 100mm × Ø12.7mm, Ø150mm × Ø12.7mm 13. Product specifications: ·Size: 580mm × 560mm × 660mm ·Weight: 39kg |

Standard accessories:

|

Number |

Name |

Quantity |

|

1 |

Saw clip pad |

3 sets in total |

|

2 |

Cross clamp |

1 set |

|

3 |

Aluminum load block |

2 pieces |

|

4 |

(50×50×10mm) |

2 pieces |

|

5 |

1 piece |

|

|

6 |

2 pieces |

|

|

7 |

Paraffin stick |

4 pieces |

|

8 |

Waterproof cover |

1 set |

|

9 |

Goggles |

1 piece |

Matters needing attention:

·It is recommended to use anti-corrosion coolant during cutting to avoid rust on the screw.

·Please clean the machine after each use, especially clean the screw with lubricant after each use. Ensure that the X, Y, and Z axes can move freely without getting stuck or rusting.

Warranty period:

·One year warranty and lifelong technical support.