T

his is Zhongda Architecture, a professional one-stop mobile home manufacturer. I am Alice, the sales manager. I will lead you to learn more about our products and

follow me!!!

.

- Product Details

- {{item.text}}

Quick Details

-

Keyword:

-

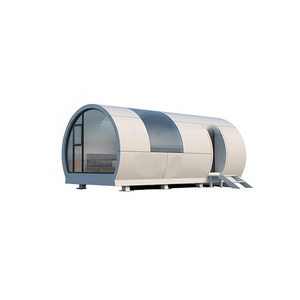

Mobile Living Container House

-

Door:

-

Steel Door

-

Window:

-

Aluminium Alloy Window

-

Waterproof:

-

For the whole hose

-

Skirting:

-

steel skirting

Quick Details

-

Place of Origin:

-

Shandong, China, Shandong ,China

-

Brand Name:

-

ZhongDa

-

Color:

-

Customized Color

-

Keyword:

-

Mobile Living Container House

-

Door:

-

Steel Door

-

Window:

-

Aluminium Alloy Window

-

Waterproof:

-

For the whole hose

-

Skirting:

-

steel skirting

My friend, welcome

Quickest, lightest and most efficient way of building housing

One crucial benefit is more efficient construction. Onsite production often gets delayed by bad weather, material shortages,planning issues and even material theft. Whereas modular construction is a highly organised and streamlined process that

can see construction project times reduced by up to 50% as models are ready before they leave the factory.

When materials are deliveredonsite, construction workers can immediately build with 100% completed parts.

Increased use of modern technologies

Another reason for the increased popularity of modular construction is the improvement in technology. Expertise in BIM, for example, is a crucial component to success. It’s no wonder then, that according to Report Linker, the market for Building Information Modelling (BIM) is expected to grow significantly in the next four years. BIM helps ensure you hit schedules and don’t go over budget. In fact, according to the Dodge Data & Analytics’ recent research on modular and prefabricated construction,

using BIM will improve budget and schedule performance by 30%.

Collaboration made easier

High-quality manufacturing and less waste

Modular buildings also use almost 67% less energy than traditional buildings.

This is partly thanks to BIM software, which makes it easy for designers to make changes and corrections before transporting materials. Small mistakes onsite can send tons of unwanted materials into landfill, and even correct materials are vulnerable to rot and damage in harsh weather.

But modular construction has put a stop to this, resulting in a 90% reduction of project material waste.

Detachable Flat pack Container Material list

|

Product specification

|

Length*width*height

|

Inner 6055mm*2438mm*2896mm/Outer 6055mm*2990mm*2896mm

|

|

|

Roof form

|

Roof tile, color steel plate

|

|

|

Drainage form

|

External drainage organization

|

|

|

Number of layers

|

≤3 layers

|

|

Design Parameters

|

Service life

|

10 years

|

|

|

Earthquake resistance

|

Level 8

|

|

|

Wind resistance

|

Level 12

|

|

|

Fire prevention

|

Class A, flame retardant

|

|

Wall

|

Wall panel

|

950 type 50mm rock wool sandwich panel

|

|

|

Wall panel

|

Double-sided color steel plate 0.3mm thick

|

|

|

Keep warm

|

Rock wool, bulk density 80KG

|

|

Door

|

specification

|

950*2070

|

|

|

Material

|

304 stainless steel

|

|

Window

|

specification

|

925*1200

|

|

|

Frame material

|

U-PVC window

|

|

|

glass

|

Single glass, 5mm

|

|

Electricity

|

Voltage

|

Not included in the standard box, can be customized according to customer requirements,

additional charges

|

|

|

wire

|

|

|

|

Distribution box

|

|

|

|

illumination

|

|

|

|

illumination

|

|

|

Decoration

|

Top and column edging

|

Color steel angle aluminum

|

|

|

Skirting

|

Brown PVC

|

Hot Searches