- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DAKIOU

-

Voltage:

-

380v/50HZ

-

Power:

-

4w

-

Dimension(L*W*H):

-

2600*1350*1700mm

-

Weight:

-

2000 kg, 2000kgs

-

Product name:

-

Automatic Forming Printing Machine Paper Cake Cup Making Machinery

-

Suitable cup size:

-

2.5-120oz

-

Suitable material:

-

150-380g/m2(single PE-coated paper)

-

Speed:

-

50-70pcs/min

-

Power source:

-

380V 50HZ

-

Total power:

-

4kw

-

packaging size:

-

2600*1350*1700mm

Quick Details

-

Production Capacity:

-

50-70pcs/min

-

Applicable Industries:

-

packaging&printing

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DAKIOU

-

Voltage:

-

380v/50HZ

-

Power:

-

4w

-

Dimension(L*W*H):

-

2600*1350*1700mm

-

Weight:

-

2000 kg, 2000kgs

-

Product name:

-

Automatic Forming Printing Machine Paper Cake Cup Making Machinery

-

Suitable cup size:

-

2.5-120oz

-

Suitable material:

-

150-380g/m2(single PE-coated paper)

-

Speed:

-

50-70pcs/min

-

Power source:

-

380V 50HZ

-

Total power:

-

4kw

-

packaging size:

-

2600*1350*1700mm

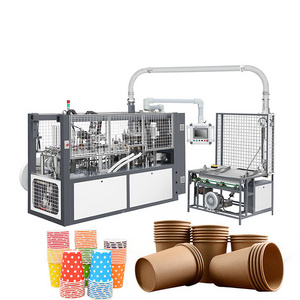

ZB-D paper cup machine is improved based on the normal chain driving type. This machine runs a whole procedure of paper-feeding, cup-fan-wall sealing, oiling, and bottom punching, heating, rolling, rimming, rounding and tripping. It is idea equipment for producing drinking cups, market cups, coffee cups, advertising cups, etc. It is widely used for hot drink and beverage.

If you need double PE coated paper cups or paper gram higher 250g/m2, we recommend you to use Ultrasonic paper cup machine. It can produce single PE coated paper cups and double PE coated paper cups.

Technical Specification:

|

Type: |

ZB-D |

|

Cup size: |

2.5-12oz(if the cup is more than 12oz the machine designed more lager ) |

|

Suitable paper material: |

150-380g/m2(single PE-coated paper) |

|

Capacity: |

50-70pcs/min |

|

Power source:: |

380V 50HZ |

|

Total power: |

4KW |

|

Weight: |

2000kgs |

|

Package size: |

2600 x 1350 x 1700 mm |

|

Working Air Source: |

Air pressure 0.4Mpa;Air out-put:0.6m3/min |

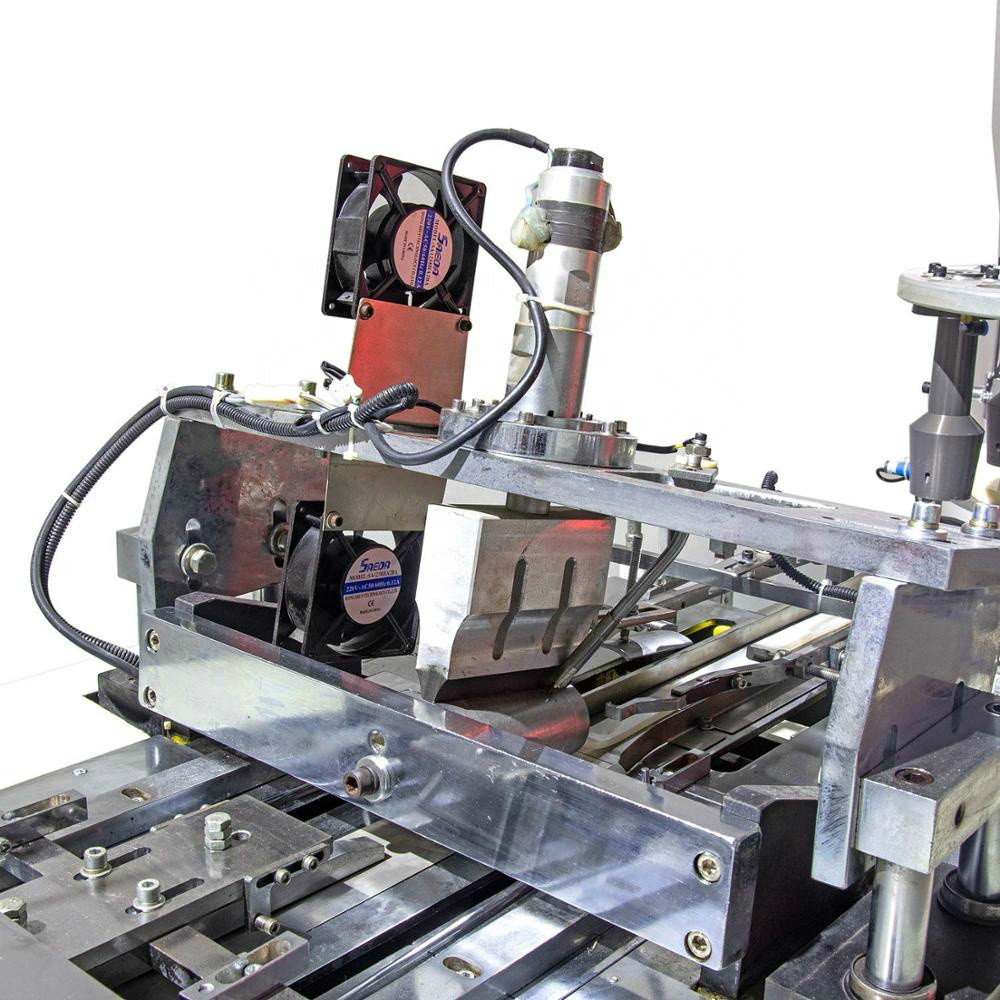

Detailed Images

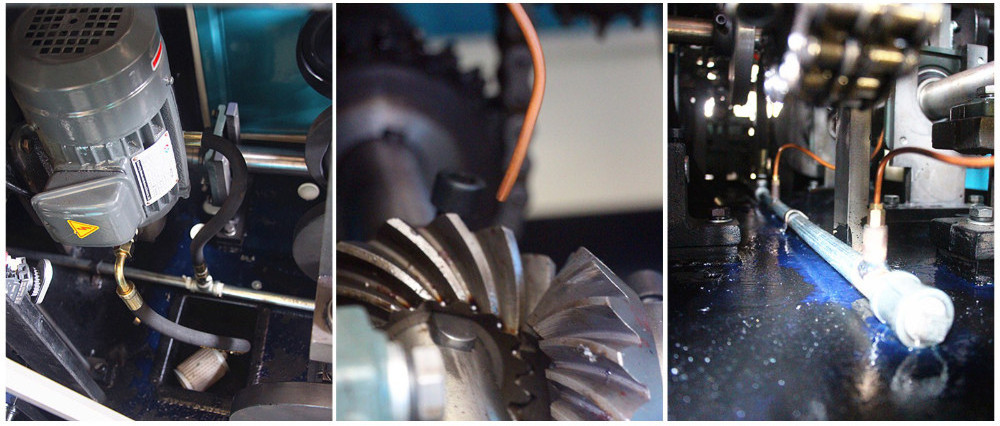

1.Use gear driving system instead of chain, more stable running and speed up.

2.Use automatic lubrication recycle system instead of oiling by hand to reduce the friction and wear between gears, improve the machine safety and reduce the cost of maintenance.

3. We use 125 type gear box, which is longer life and more accurate.Normally,100 type gear box is used.

4.100 type speed reducer is used instead 80.

5.New design knurling wheel is used to guarantee the even pressure and better bottom sealing.

6. Cup folding parts is controlled by three separate cams, and each folding clip can be adjusted by itself.

7. We use manipulator to transfer the cup body instead of falling itself by pipe,It is more stable and accurate under the fast running.