- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

Other

-

Place of Origin:

-

China

-

Brand Name:

-

ZYZG

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

2700*1600*2480mm

-

Weight:

-

6 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Keyword:

-

roof tile making machine

-

Application:

-

steel roof tile making

-

tile thickness:

-

0.2-0.8 for usual

-

Material:

-

Steel Material

-

Color:

-

customizabe

-

Usage:

-

Roof Tile Panel,wall decoration

-

worktable size:

-

customizabe

-

Dimension:

-

2700*1600*2480mm

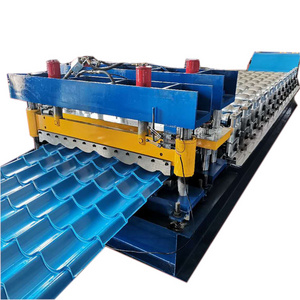

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

80%

-

Rolling thinckness:

-

Other

-

Place of Origin:

-

China

-

Brand Name:

-

ZYZG

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

2700*1600*2480mm

-

Weight:

-

6 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Keyword:

-

roof tile making machine

-

Application:

-

steel roof tile making

-

tile thickness:

-

0.2-0.8 for usual

-

Material:

-

Steel Material

-

Color:

-

customizabe

-

Usage:

-

Roof Tile Panel,wall decoration

-

worktable size:

-

customizabe

-

Dimension:

-

2700*1600*2480mm

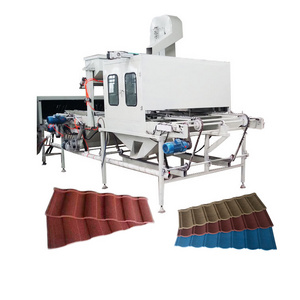

stamping press hydraulic 3D wall panels metal roof tile making machine

hydraulic 3D wall panels metal roof tile making machine

Features:

1.Hydraulic pump design low noise, high efficiency, long life, the key parts do not leak, parts wear

is very small, saving a lot of maintenance.

2.The hydraulic cylinder is stable under normal operating conditions and the noise is very low.

3.making machine Worktable solid and reliable, long-term use, no deformation, effectively ensure

that products fully meet the set standards.

4.Sealing performance of the ceiling machine, on the one hand,

the use of precision cutting process integrated molding,

on the other hand with excellent imported sealing materials,

more than ten years of continuous improvement and innovation, has been very mature.

Product main technical parameters:

|

Specification |

Unit |

YQ32-315A |

YQ32-315B |

YQ32-400 |

YQ32-500 |

|

|

Nominal force |

Kn |

3150 |

3150 |

4000 |

5000 |

|

|

Max pressure of hydraulic system |

Mpa |

25 |

25 |

25 |

25 |

|

|

Max. Opening height |

mm |

1250 |

1250 |

1250 |

1500 |

|

|

Slider effective stroke |

mm |

800 |

800 |

800 |

900 |

|

|

Working table size |

mm |

1260*1160 |

1000*1100 |

1260*1160 |

1400*1400 |

|

|

Nominal force of Ejection cylinder |

Kn |

630 |

630 |

630 |

1000 |

|

|

Ejection stroke |

mm |

300 |

300 |

300 |

300 |

|

|

Slider working speed (empty travel) |

Mm/s |

120 |

120 |

120 |

150 |

|

|

Slider working speed (press) |

Mm/s |

8-15 |

8-15 |

8-15 |

10-22 |

|

|

Slider working speed (Return stroke) |

Mm/s |

90 |

90 |

90 |

120 |

|

Function

Used in metal material tensile, punching ,bending, flanging, cold extrusion and Various kinds of stamping process. It also could be used in alignment and press-fit , the pressing of powder products and plastic products , And the press forming of insulating material

hydraulic 3D wall panels metal roof tile making machine basic design:

Man-machine interaction, taking full account of the specific requirements of the use, manual, semi-

automatic, fully automatic use of free switching.

Visual operation interface, image operation guide, get started very fast.

Nominal pressure, opening height, slider travel, work surface size, running speed, body length and

width of

press machine

,

are all can be customized.

Color stone steel roof tile is a brand new roofing material produced with durable

galvanized steel plate

and takes the high quality watercraft

acrylic resin

as the adhesives, the weather resistant

nature color sand

or dyed nature sand as the surface layer through unique technical process.

It is high technological product combining creation, composition and is

environmental friendly

and does no harm to people and environment.

Packaging Details

Internal plastic moisture-proof anti-rust packaging,

External wooden packaging,

Exclusive container transport.

Delivery Time for High Speed Four Column Hydraulic Press Machine for Oil Filter:

Shipped in 30 days after payment

Our services are divided into pre-sale, sales, after-sale three parts.

Pre-sale

to provide detailed advice, the program recommended to the factory inspection, as far as possible to meet your questions and needs.

Sales

can support samples, support diversified payment methods, the solid forklift tire press machine production process transparent, standardized and quickly stocking.

After-sales

support diversification guidance, training, voice and video images, and even solid forklift tire press machine overseas site installation, on-site training, home maintenance, continuous return visit customers concerned about the use