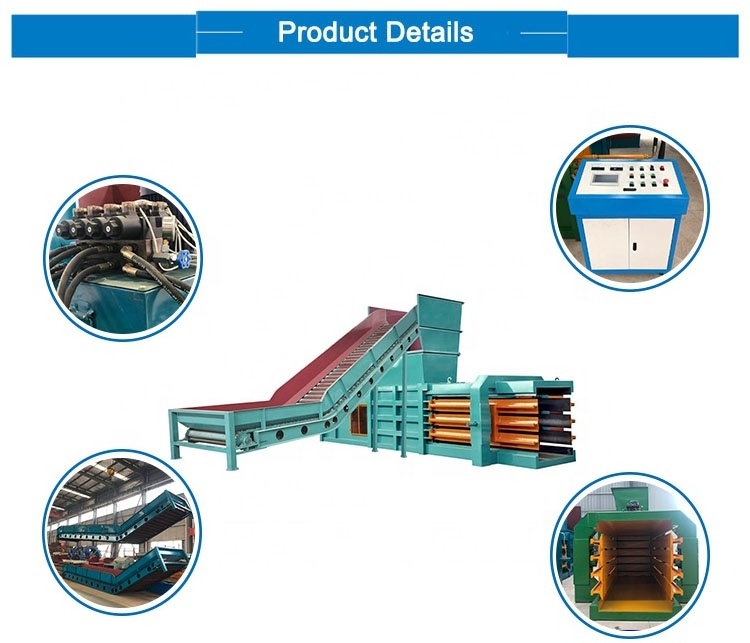

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Shunfu

-

Weight:

-

0.5-20T, 1-15T

-

Dimension(L*W*H):

-

Based on Machine Model/customized

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Pakistan, Morocco, Chile, UAE, Colombia, Algeria

-

After-sales Service Provided:

-

Online support, Engineers available to service machinery overseas

-

Product name:

-

aluminium can press baler machine

-

Keyword:

-

waste baler machine

-

Machine type:

-

aluminium cans press baler machine

-

Techinical service:

-

Support

-

Capacity:

-

11packages/h

-

Packing material:

-

Paper, Wood, standard package/container

-

Control system:

-

Control cabinet

-

Main Function:

-

Baling all waste materical

-

Sealing type:

-

Rope type

-

Certification:

-

CE, ISO9001:2008, SGS

Quick Details

-

Voltage:

-

220V/380V, 220V/380V

-

Power:

-

25-65KW, 15-26kw

-

Place of Origin:

-

Henan, China(Mainland)

-

Brand Name:

-

Shunfu

-

Weight:

-

0.5-20T, 1-15T

-

Dimension(L*W*H):

-

Based on Machine Model/customized

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Pakistan, Morocco, Chile, UAE, Colombia, Algeria

-

After-sales Service Provided:

-

Online support, Engineers available to service machinery overseas

-

Product name:

-

aluminium can press baler machine

-

Keyword:

-

waste baler machine

-

Machine type:

-

aluminium cans press baler machine

-

Techinical service:

-

Support

-

Capacity:

-

11packages/h

-

Packing material:

-

Paper, Wood, standard package/container

-

Control system:

-

Control cabinet

-

Main Function:

-

Baling all waste materical

-

Sealing type:

-

Rope type

-

Certification:

-

CE, ISO9001:2008, SGS

rope type aluminium cans press waste scrap tire baler machine for sale

A PPLICATION

The textile baler machine is mainly used in the large supermarket, large and middle scope recycling station and factory etc. to press the loose materials into bales.

This baler is suitable to press waste paper, carton, cardboard, PET Bottle, Plastic Film, woven bag, straw, sponge and zip-top can.etc.

T ECHNICAL PARAMETERS

|

Model |

Automatic waste paper baler machine |

|

|

Dynamic system |

High and low pressure assembly of hydraulic system |

|

|

Working paramters |

22KW+15KW Hydraulic pump two |

|

|

Nominal thrust |

Rated displacement:160ml/r Rated pressure:31.5MPA |

|

|

Pressure |

28MPA |

|

|

Power |

3PH380V |

|

|

Control system |

PLC,Object detection, operation automatic control, manual button operation |

|

|

Hydraulic oil number |

46# Antiwear hydraulic oil |

|

|

Machine Parameters |

Feeding size |

(Length*Width)1685*860mm |

|

Package size |

(Width*High)900*1100mm |

|

|

Package density |

≥400-450KG/m33 |

|

|

Capacity |

8-11tons(8-11bags)/hour |

|

|

Strapping |

Tempered wire 2.8/3.2mm,Four wires, manual strapping |

|

|

Installing size |

a=8000,b=2800,c=5000,d=3200,e1800

|

|

F EATURES

- Hydraulic cylinders adjust size of output opening, safe and stable; easy to change the bale density.

- Integrative automatic control with PLC, button and touch screen, requiring less work labor.

- Free to set the bale length, automatic record of bale number, making it convenient to calculate the production and cost.

- Decentralized knifes increases much the cutting efficiency and reduces the machine load.

- Automatic winding strapping method, simple structure and convenient maintenance, strong strapping, making it convenient to transport.

- Duplex-stage wire pushing system, high efficiency, and less space required for installation.

- Automatic speed adjustment, increasing the production and decrease the consumption.

- Pressure pre-set, overload protection, intelligent control and self- inspection program.

- Independent emergency stop button to stop the machine at any time.

- Auto micro-adjustment assembly method is used for hydraulic cylinder, reducing the torque and extending the service life.

- Strong load bearing beam and fram structure ensures machine run stably and service longer time.

C ONFIGURATION STATE

< Main frame system >

High quality heavy steel plate, aerated welding, casting solid framework, advanced mechanical design, make the equipment durable.

< Conveying system >

High quality steel frame, high strength steel belt.

< Hydraulic system >

Hydraulic pumps, solenoid valves and hydraulic cylinders, oil seals and other key components imported components, making the packing pressure, speed, durability, noise.

< Electronic control system >

SIEMENS motor, the original MITSUBISHI PLC programming controller. Other buttons, sensors, infrared shots, remote control systems and other key parts imported components, simple operation, easy maintenance.

< Safety alarm system >

Program control, five safety, automatic locking, stop alarm. When the equipment is misoperation, the power supply is out of phase, the pressure is too high, and the person goes into the packing mouth, the machine can stop the alarm automatically.

L EAD TIME

25 days after receiving 30% deposite.