- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

2800 KG

-

Power (kW):

-

5kw/h

-

Over size:

-

9650*1780*1580mm

-

Table size:

-

2550*1300/1150mm

-

Working height:

-

≤50mm

-

Motor power:

-

23.8kw

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SAGA

-

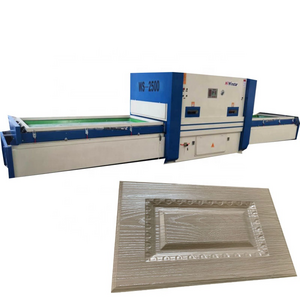

Machine Type:

-

vacuum press machine

-

Weight (KG):

-

2800 KG

-

Power (kW):

-

5kw/h

-

Over size:

-

9650*1780*1580mm

-

Table size:

-

2550*1300/1150mm

-

Working height:

-

≤50mm

-

Motor power:

-

23.8kw

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

Product Description

Detail Images

Electrical Element

Vacuum Pump

Frequency Conver

Direct Motor

Electric Aluminum Plate

Features:

1、Top-e series of special-shaped laminating machine is suitable for panel furniture, cabinet, wardrobe door, sliding door, office table and other home furnishing industries (mainly covering high-grade PVC film, transfer film and other decorative materials on the surface of wood plate).

2、The top-e series model is the latest upgraded version. After the upgraded version, it is mainly reflected in: 1. It reduces the previous tedious operation steps and saves time; 2. It reduces the traditional fault points and improves the working efficiency; 3. The high-quality re upgrading of main components improves the stability.

3、This machine is double station automatic operation mode. The left and right two stations can operate continuously. When the left platform is working, the right platform places the workpiece; when the right platform is working, the left platform places the workpiece. There is no need to wait to maximize efficiency.

4、The operation interface adopts automatic digital display control, which is easy to understand. According to the PVC film of different materials, adjust the corresponding parameters (the factory has provided the parameter table for reference). When operating, just press the start button, which is fast and time-saving.

5、Equipped with high-speed vacuum pump, rated speed of 100m ³ / h and super large vacuum tank. It can quickly reach the required pressure in a short time, with fast pumping speed and large force. Shorten the forming time and improve the working efficiency.

6、There are two kinds of functions of absorbing and forming. The function mode can be selected freely according to the different PVC materials or the complexity of panel modeling. It can solve the problems of PVC material rupture and insufficient linear lamination in the process of absorption and coating.

7、Equipped with special electric aluminum plate for heating, fast temperature rise, uniform heat radiation; equipped with high-quality aluminum silicate plate insulation layer, heat insulation, fire protection, excellent insulation effect. It overcomes the problems of large temperature difference and high power consumption.

8、Equipped with a vacuum butt joint device without pipe, two problems are solved: 1. The traditional vacuum hose is easy to break; 2. The traditional vacuum steel pipe is worn for a long time, resulting in many air leakage points. This device effectively eliminates the fault point.

9、The workbench is driven by high-speed direct connected motor, and frequency conversion is adopted for speed regulation. The way of high-speed operation and slow down stop effectively prevents the displacement of plates. And shorten the running time, improve the working efficiency.

10、One key quick locking pressing frame device is equipped, which is simple and fast, reduces tedious operation steps and saves time.

11、Equipped with high-quality high-end brand electrical components and high-tempreature resistant heating cable,with high stability.

12、In response to the requirements of the majority of users, this model improves the interchangeability of wide and narrow tables. No need to change the main machine, only need to change the wide or narrow platform, can carry out the processing and manufacturing of wide and narrow PVC film, saving cost.

13、Note: the width of PVC film is 1400mm, please choose 1300mm table top, which is suitable for cabinet door, office desk, etc;PVC film width 1250mm, please choose 1150mm table, suitable for indoor doors, sliding doors, speakers, etc.

Quick locking frame:

Equipped with one key quick locking pressing frame device, it is simple and quick to save time and reduce failure points.

High speed direct connected motor:

The worktable is driven by high-speed direct connected motor, and speed conversion is adopted for speed regulation. The way of high-speed operation and slow down stop effectively prevents the displacement of plates. Shorten the running time, reduce the failure, give you a perfect feeling

Multifunctional covering device:

Equipped with two kinds of functions, it can effectively solve the problems of PVC film breaking or failure gluing of high or very deep shape. It can be applied to all kinds of PVC materials of high, middle and low grade, with wide application range and high yield.

Tubeless butt joint device:

There are two problems to be solved: 1. The traditional vacuum hose is easy to break; 2. The traditional vacuum steel pipe is easy to wear and tear for a long time, resulting in many air leakage points. This device effectively eliminates the fault point.

High speed vacuum pump:

Equipped with high-speed vacuum pump, rated speed of 100m ³ / h and super large vacuum tank. It can quickly reach the required pressure in a short time, with fast pumping speed and large force. Shorten the forming time and improve the working efficiency.

Special electric aluminum plate:

It is equipped with special electric aluminum plate for heating, with fast temperature rise and uniform heat radiation; it is equipped with high-quality aluminum silicate plate for heat preservation, heat insulation and fire prevention, with excellent heat preservation effect. It overcomes the problems of large temperature difference and high power consumption.

Up-floating heating mode:

The up floating heating mode of PVC film can effectively solve the wrinkle or internal and external surface phenomenon of medium and low grade soft PVC film, and improve the heating uniformity of PVC film surface.

Control panel

:

Classical durable control system, with mature setting program, easy to control and durable for lifelong use.

|

Model

|

TOP-E260 special vacuum laminating machine

|

|

|

|

Model selection

|

The standard version

|

The longer version

|

|

|

Overall size

|

9650*1750*1580mm

|

11000*1780*1580mm

|

|

|

Working table size

|

2550*1300/1150mm

|

3000*1300/1150mm

|

|

|

The processing thickness

|

≤50mm

|

≤50mm

|

|

|

The installed power

|

23.8kw

|

26.2kw

|

|

|

Power consumption

|

5kw/h

|

5kw/h

|

|

|

The total weight

|

2800kg

|

3200kg

|

|

|

Model

|

TOP-F280 special vacuum laminating machine

|

|

|

|

Model selection

|

The standard version

|

The longer version

|

|

|

Overall size

|

9650*1750*1680mm

|

11000*1780*1680mm

|

|

|

Working table size

|

2550*1300mm

|

3000*1300mm

|

|

|

The processing thickness

|

≤50mm

|

≤50mm

|

|

|

The installed power

|

37kw

|

40.6kw

|

|

|

Power consumption

|

7kw/h

|

7kw/h

|

|

|

The total weight

|

3200kg

|

3600kg

|

|

Product display

Related Products

Packing & Delivery

Our Company

SAGA located in Lunjiao Foshan, Guangdong, Lunjiao is a world famous town for woodworking machinery production, while SAGA is a union brand of several woodworking machinery suppliers in this town including some main members like: saga hf which is professional on high frequency vacuum dryer, HJD who is specialized on 4side planer and rip saw, JHC is focus on solid wood CNC machine, well Linsaw is a professional heavy duty sawmill producer, Each member got at least more than 15year's experience on their field, SAGA itself have 15years of experience on solid wood processing. The sale and service is all from a single source-SAGA, thus customer just rely on a single source for whole plan solid wood working machinery. You can not only get reasonable price(as we are manufacture) but also quick service responds,while those partners tightly cooperate to ensure the profession, precise and excellent service.

Rich experience and strong technology and research team, passions for wood working, saga union offer more precise solution for solid wood production like: sawing, wood drying, planing edge gluing to shaping, we have successfully served hundreds of factory all over the world like: wood panel production, bedroom furniture, kitchen cabinet, solid wood doors, curved plywood etc, not only single machine, but also whole factory plan.

We use strict inspection standard to both production and service, neutral design which focus on the user to make your production easy and smooth.

Rich experience and strong technology and research team, passions for wood working, saga union offer more precise solution for solid wood production like: sawing, wood drying, planing edge gluing to shaping, we have successfully served hundreds of factory all over the world like: wood panel production, bedroom furniture, kitchen cabinet, solid wood doors, curved plywood etc, not only single machine, but also whole factory plan.

We use strict inspection standard to both production and service, neutral design which focus on the user to make your production easy and smooth.

10000square meter showing room 365 days open 365 days non -stop exhibition id always there ,no trouble of tired travel around ,no risk of bad quality and un-trustable service,good price and time saving ,comfortable felling ,is Nanji.For wood working machinery and accessories.Most of the member in this hall is saga's partner .

15 years of experience for wood working machine .Export and service, got various plan for many wood.

Products, mature after sale service team .

All the members of SAGA are expert in their own field.

We cooperate to serve you and solve your problem.

Products, mature after sale service team .

All the members of SAGA are expert in their own field.

We cooperate to serve you and solve your problem.

FAQ

1.What is your price term and payment term?

We offer FOB, CIF, CNF EXW price, we accept TT/LC or other negotiate.

In stock: 100% payment Not in stock: 30-40% deposit for confirm the order, rest is paid before shipment, some customized machine may need 50% deposit.

In stock: 100% payment Not in stock: 30-40% deposit for confirm the order, rest is paid before shipment, some customized machine may need 50% deposit.

2.How long for delivery?

Some standard machine or commercial machine, always in stock, for high value machine or customized machine, may takes 30-40 days

production.

production.

3.After sale and warranty?

Most machine got 1 year warranty except some consumption spare, all spare within warranty period is free for change, in the condition that machine is running according to the manual book(saga got rights for explain).

4.Installation for complex machine.

We have 20 years of experience for installation all over the world for big and complex machine, customer response for good and living as well as transport, some area may be served by our agent. For commercial machine, we will do our best to offer installation guiding video.

5.Free spare parts for change .

Most of our machine use international standard, especially electric spare parts, if not, we offer free spare parts to avoid any urgent condition to minimize risk of downtime.

6.Safety for the machine and packing .

We have mature experience for sea transport packing, for some irregular shape machine, we will do special fix and tight on container to avoid any risk of any broken.

Hot Searches