Can provide Italy imported ECS software which can provide more than 20 languages

- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

100

-

Cutting Accuracy(mm):

-

0.1

-

Brand Name:

-

WAMIT

-

Voltage:

-

220V/380V/415V

-

Rated Power:

-

7.5kw

-

Dimension(L*W*H):

-

500*500mm

-

Year:

-

NEWEST

-

Weight (KG):

-

2000

-

Cutting thickness:

-

0-100mm

-

Pressure:

-

200Mpa, 30000psi

-

Pump type:

-

direct drive pump

-

Cutting accuracy:

-

±0.1mm

-

powewr:

-

7.5kw

-

Power Requirement:

-

(415v/50hz), 380V/50HZ, ( 220v/60hz), 3 phrase

-

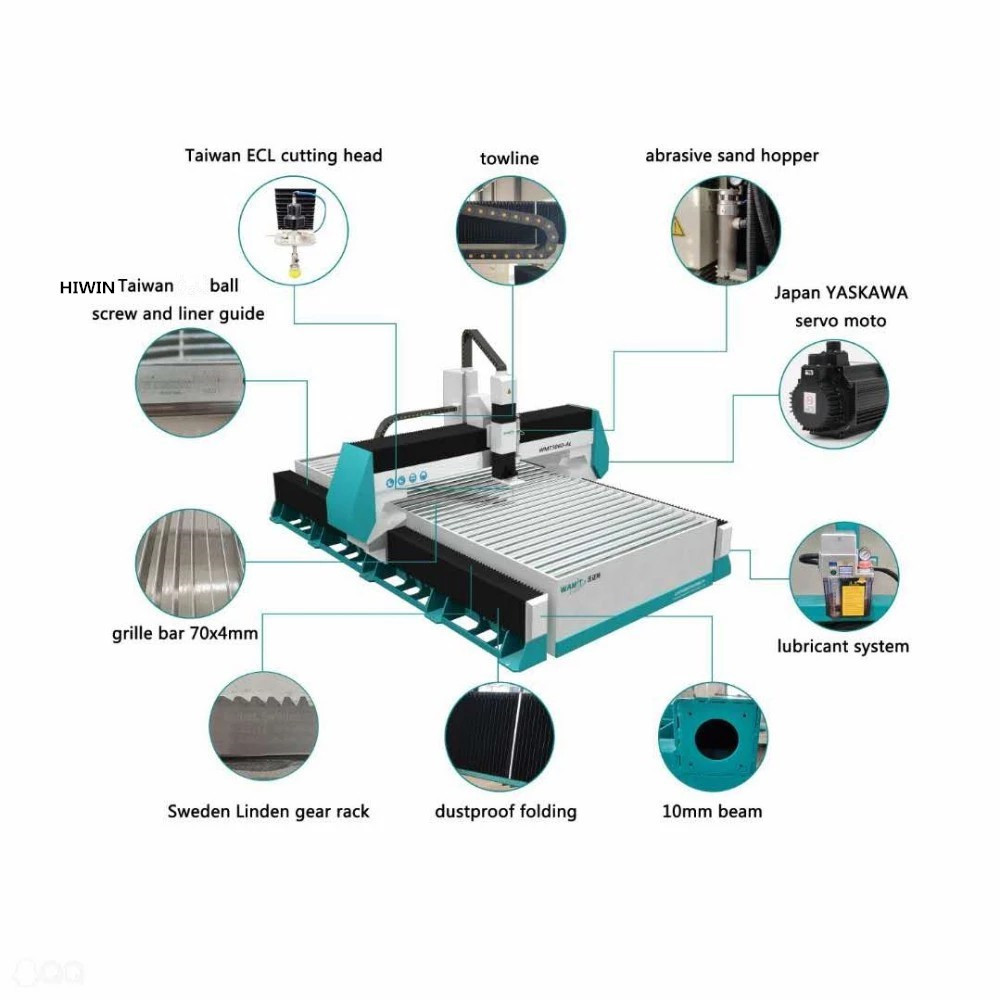

linear guider:

-

imported from TAIWAN HIWIN

-

Way of drive:

-

servo motor and driver

-

Control accuracy:

-

±0.05mm

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Shandong, China, Shandong, China (Mainland)

-

Table Travel (X) (mm):

-

500

-

Table Travel (Y) (mm):

-

500

-

Table Travel (Z) (mm):

-

100

-

Cutting Accuracy(mm):

-

0.1

-

Brand Name:

-

WAMIT

-

Voltage:

-

220V/380V/415V

-

Rated Power:

-

7.5kw

-

Dimension(L*W*H):

-

500*500mm

-

Year:

-

NEWEST

-

Weight (KG):

-

2000

-

Cutting thickness:

-

0-100mm

-

Pressure:

-

200Mpa, 30000psi

-

Pump type:

-

direct drive pump

-

Cutting accuracy:

-

±0.1mm

-

powewr:

-

7.5kw

-

Power Requirement:

-

(415v/50hz), 380V/50HZ, ( 220v/60hz), 3 phrase

-

linear guider:

-

imported from TAIWAN HIWIN

-

Way of drive:

-

servo motor and driver

-

Control accuracy:

-

±0.05mm

-

Certification:

-

CE ISO

Products Description

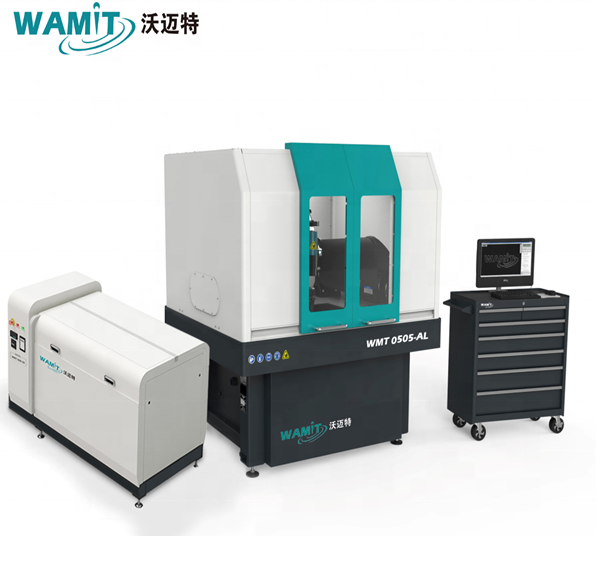

desktop small waterjet cutter with 30000psi direct drive pump

widely used in laboratory and home work

The gantry-style balanced design structure is more stable and improves the accuracy of the machine. Ultra-high pressure cutter head, which can be cut with pure water and sand. It has 3-axis and 5-axis cutter heads for vertical and non-vertical cutting with a maximum cutting angle of 60 degrees. The X/Y axis adopts the labyrinth waterproof and sandproof double protection system. The X/Y axis adopts Taiwan's high-quality guide rail and Swedish ball screw. It is durable and the Z-axis fully enclosed structure is guaranteed to be free from water and sand. Heavy-duty machine tools, high-temperature forging, so that the machine will not be deformed during use. China's first generation of self-designed ultra-high pressure servo direct drive pumps are more energy efficient, environmentally friendly and light, and ultra high pressure booster pumps are easier to operate and maintain. The CNC control system uses the WEIHONG professional waterjet cutting CNC system.

we also have ITALY imported software which support more than 20 languages.

More advantages

1. Automatic lubrication system from the Valley of Japan.

2. The internal components are selected from Schneider International brand, with first-class quality and reliable work.

3. Way of drive : Servo ( drives and motors are from Japan YASKAWA ).

4. High precision, Ensure cutting results.

5.

Provide customizable services.

6.

After-sales Service:

Field maintenance and repair service,

Online support,

Field installation, commissioning and training,

Video technical support,

Free spare parts.

7.ECL cutting head

Control system

Adopt industrial PC

Dedicated water jet cutting software with graphic simulation running function, graphic input automatic programming function.

• Support for DXF files.

• Support forward and reverse processing functions.

• Uniform speed control function.

• Two modes of segmentation and smooth machining.

• Automatic processing with small arc speed.

• Coordinate recovery function after power off.

• Double lift speed parameter function.

• With cycle processing.

• Convenient pause to continue and start machining in any segment.

• Free time delay setting.

• Apply SIEMENS PLC instead of relay, buttons are Schneider.

Size

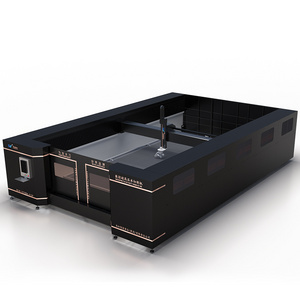

Can be customized to any size, mini platform or ultra-large platform or other size can be customized.

|

SPECIFICATIONS FOR WATER JET CUTTING MACHINE

|

|

|

|

|

|

|

||||||

|

Model

|

|

WMT 1010

|

WMT 2050

|

WMT 3020

|

WMT 3080

|

WMT 5030

|

||||||

|

Cutting table

|

X axis(mm)

|

1200

|

2200

|

3200

|

3200

|

5200

|

||||||

|

|

Y axis(mm)

|

1200

|

5200

|

2200

|

8200

|

3200

|

||||||

|

Max.cutting range(mm)

|

X axis(mm)

|

1000

|

2000

|

3000

|

3000

|

5000

|

||||||

|

|

Y axis(mm)

|

1000

|

5000

|

2000

|

8000

|

3000

|

||||||

|

|

Z axis(mm)

|

250

|

250

|

250

|

250

|

250

|

||||||

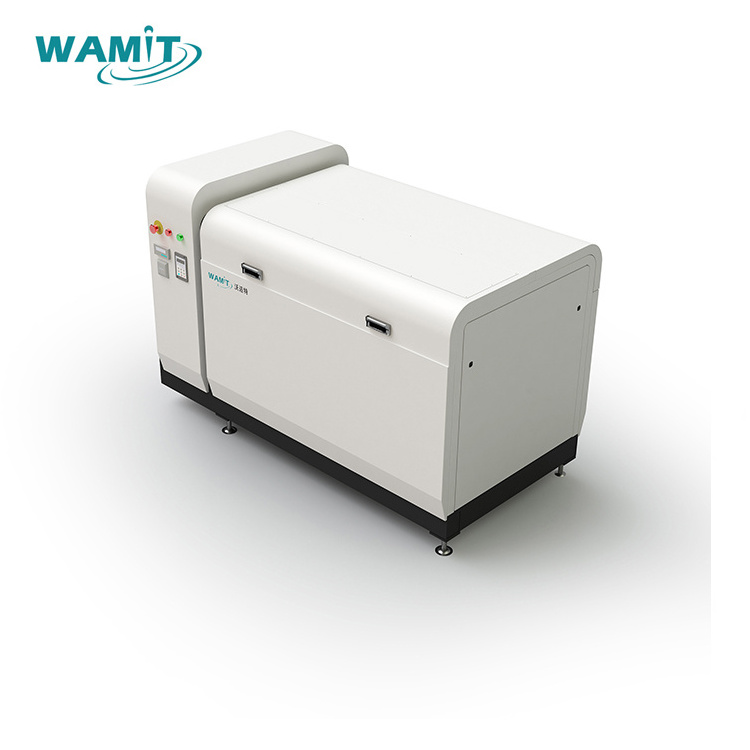

WAMIT servo direct drive pump represents a new generation of high-efficiency, energy-saving ultra-high pressure pump, which is the first large R&D in China. Servo motor driven direct drive intensifier system.

7.5kw direct drive pump

Model: WMT SDD 20

Maximum pressure: 30000Psi.

Gemstone aperture: 0.33mm.

Displacement: 3.0 l/min.

Inlet pressure: 0.4MPa.

Main motor power: 7.5KW.

Dimensions: 1680*900*1100mm

Double row water filtration system (5Micron, 1micron, series)

Intelligent start and stop function.

Over-pressure automatic shutdown and under-pressure automatic protection.

Advantages of the WAMIT servo direct drive pump:

A: Energy saving: The main motor adopts a torque motor of 15KW, compared with the motor of the 37KW hydraulic high pressure intensifier system, the power consumption can be saved by 60%-70%.

B: Environmental protection: the use of servo direct drive, no hydraulic system, with self-cooling function. As we all know, hydraulic The hydraulic intensifier system must be filled with 110L of anti-wear hydraulic oil to work, and the heat generated by the hydraulic oil is also cooled by the oil cooler. The direct drive pump is completely free of hydraulic oil and cooling system.

C: High efficiency: Direct drive pump provides a higher pressure output ratio, cutting speed is 20 to 50% faster than the same equipment in the market.

E: Low noise: almost no noise when working.

F: Small weight: The total weight of the direct drive pump is less than 600kg, and the movement is flexible. The weight of the hydraulic intensifier pump is 1000kg.

G: Beautiful appearance: The structure is reasonable in design and beautiful in appearance, because the direct drive pump does not have a hydraulic system, Thereby avoiding the leakage of the hydraulic oil (the hydraulic seal will be damaged for a long time use, causing the hydraulic oil to leak), eliminates the contamination of equipment by oil stains.

Production Process

Heat treatment

620 degrees in the furnace for 5 hours, down to 300 degrees for 3 hours, then naturally cooled in the furnace.eliminate internal stress in the welded frame.no deformation occurs during frame use,guarantee better cutting precision.

Shot blasting and powder coating

Remove impurities such as surface oxide scale to improve appearance quality.it can improve the fatigue fracture resistance of materials, prevent fatigue failure, plastic deformation and brittle fracture, and improve fatigue life.

Test

Test the straightness and parallelism of linear guide rail with precision measuring instruments.

Guaranteed higher precision when the equipment is running after the linear guide rail is installed.

Calibration

Calibrating equipment precision with a laser interferometer.guaranteed more accurate cutting precision.

Cutting Speed

|

Material

|

Specification

|

Speed(mm/min)

|

|

|

|

|

|

Servo direct drive pump

|

Hydraulic intensifier pump

|

|

|

Carbon steel plate

|

10mm

|

330

|

270

|

|

|

|

12mm

|

280

|

220

|

|

|

|

14mm

|

240

|

180

|

|

|

|

16mm

|

200

|

140

|

|

|

|

20mm

|

170

|

110

|

|

|

|

22mm

|

140

|

85

|

|

|

Aluminum plate

|

12mm

|

800

|

600

|

|

|

|

30mm

|

200

|

160

|

|

|

Glass

|

5mm

|

2000

|

1600

|

|

|

|

8mm

|

1800

|

1400

|

|

|

|

10mm

|

1500

|

1100

|

|

|

|

12mm

|

1200

|

900

|

|

|

|

14mm

|

1000

|

700

|

|

|

Ceramic tile

|

12mm

|

2000

|

1500

|

|

|

|

14mm

|

1400

|

900

|

|

|

Microcrystal stone

|

16mm

|

1200

|

900

|

|

|

Marble

|

25mm

|

1000

|

800

|

|

|

|

30mm

|

800

|

600

|

|

Our Customer

Packaging & Shipping

FAQ

1. Are you manufacturer or trading company?

We are manufacturer of water jet cutting machine in JINAN city, Shandong, China.

2. What kind of material does your water jet cutting machine can cut?

There are plenty materials our water jet cutting machine can cut, such as stone, ceramic, quartz, glass, foam, plastic, rubber, copper, brass, aluminum, mild steel, pre-hardened steel, titanium, inconel and cast alloy.

3. What's your CNC water jet cutting machine's max. cutting thickness?

Generally speaking, if cut steel the max thickness of our water jet cutting machine can be up to 240mm, but we suggest cut no more than 150mm for smooth cutting. Now our Z axis distance is 170mm, we can customize for customers. Regular thickness please refer to: Marble is 0-120mm; granite is 0-110mm; tiles are 0-40mm; glass and mosaic is 0-80mm; steel, stainless steel, copper is 0-60mm; aluminum is 0-80mm; plastic, acrylic, foam is 0-200mm.

4. How we supply after-service?

Some countries we have after-service department, we will provide local service, if have no local service, we will arrange engineer for overseas installation and training. The installation and training time is generally 7-10 days. And we also can provide installation videos.

5. What's your delivery time?

Generally speaking is 30 days. if have stock, 7-15 days.

Hot Searches