- Product Details

- {{item.text}}

Quick Details

-

Machinery Capacity:

-

1-1.5tons/day

-

Machinery Function:

-

Shrimp grading machine

-

Application:

-

Shrimp Grading

-

Conveyor belt material:

-

high-strength PVC plastic steel

-

Body material:

-

Stainless steel tube

-

Roller Quantity:

-

12

-

Dimensions:

-

6500*4000*2200

-

Voltage:

-

380V

-

Capacity:

-

1ton-1.5ton/day

-

Advantage:

-

Easy Operation High Efficiency

-

Certification:

-

CE

Quick Details

-

Weight (KG):

-

1700

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Grand

-

Machinery Capacity:

-

1-1.5tons/day

-

Machinery Function:

-

Shrimp grading machine

-

Application:

-

Shrimp Grading

-

Conveyor belt material:

-

high-strength PVC plastic steel

-

Body material:

-

Stainless steel tube

-

Roller Quantity:

-

12

-

Dimensions:

-

6500*4000*2200

-

Voltage:

-

380V

-

Capacity:

-

1ton-1.5ton/day

-

Advantage:

-

Easy Operation High Efficiency

-

Certification:

-

CE

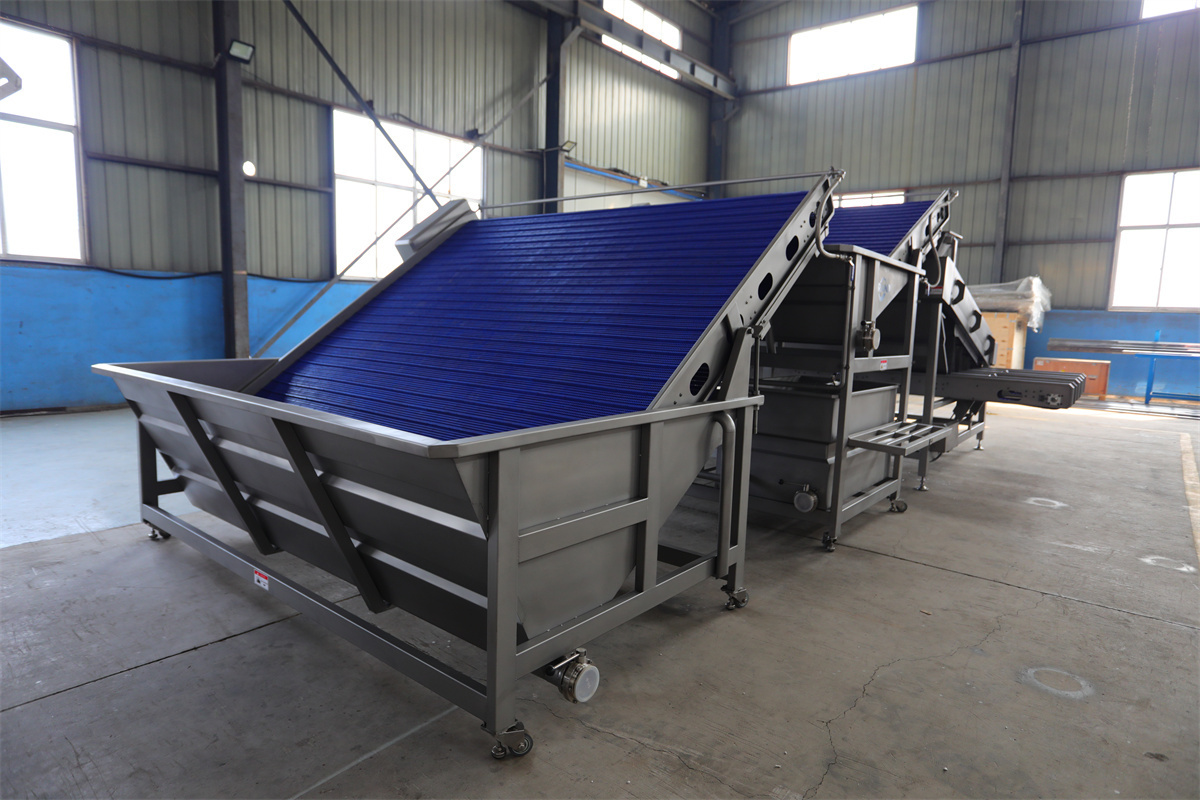

Description of 12 rollers stainless steel shrimp grading machine

( 1) Dimensions: 6500*4000*2200

(2) Roller: (∅ 125 × 130mm) 12 stainless steel rollers

(3) Conveyor belt size: 1746mm wide plastic mesh belt, 10mm height of the baffle, two-stage hoist.

(4) Conveyor belt material: high-strength PVC plastic steel belt

(5) Power: (1.5KW × 1 set), (0.4KW × 2 sets), (0.755KW × 2 sets), (stainless steel pure water pump 1.1KW × 1 set), (MITSUBISHI inverter)

(6) Lifting groove material: sus1.5mm 304# stainless steel plate

(7) Body material: (∅114×2.5mm) stainless steel tube

(8) Water supply part: stainless steel fittings on the cover, stainless steel pump PPR fittings

(9) Rotating part: UCF205 stainless steel bearing, shaft drive (bearings are all stainless steel)

(10) Power distribution cabinet: microcomputer control, stainless steel electric cabinet

(11) Production: 1 ton - 1.5 tons per hour

Main Usage:

The shrimp grading machine is suitable for grading all type of shrimps , Balaam fishes , and other small fish ,such as Tilapia, now it is mainly applied to classify and process large amount shrimp.

Main Character:

Put the raw materials into the first grading tank to convey and process automatically;

work is fast , accurate and uniform to classify;

There is no breakage to the products;

Save energy cost and has high working efficiency;

The material conveyor and material recovering conveyor are all made of food grade plastic,have no pollution to the food and meet food sanitation requirements.

The space between screen rollers can be adjusted by hand, or self-regulate, and it is very flexible and convenient to adjust.

Working Principle

This shrimp grading machine mainly consists of a driving device, a transmission drum, a conveyer belt, a groove type upper supporting roller, a lower supporting roller, a rack, a sweeper, a tension device, a turnabout drum, a guide chute, an electric control device, etc.

The conveyer belt winds about the transmission drum and the turnabout drum in the tail part to form an annular sealing belt. The conveyer belt winds about the transmission drum and the turnabout drum in the tail part to form an annular sealing belt. The tension device enables the conveyer belt to have sufficient tensile force. During working, the transmission drum is driven by a speed reducer to drive the conveyer belt through a tooth profile, thus the materials enter from a feeding device to move along with the conveyer belt, and they reach the discharge port via a certain distance to shift to the next process

The smallest size of shrimp will be sent to the outlet of conveyor first, and the other size of shrimps will slide down. The biggest size of shrimp is the last grade. The machine is designed to be six grades: 16/20, 21/25, 26/30, 31/35, 36/40 and 41/50. If there are much more grades in one batch, select the remaining shrimps once again.

|

Certificates

|

|

|

|

|||

|

Packaging and Delivery

|

|

|

|

|||

|

FAQ

|

|

|

|

|||

1 Q:Can you do OEM or produce the product in our design?

A:Yes

2 Q:Do you accept sample order?

A:Yes,but the sample is on your charge

3 Q: What is your warranty?

A: We can assure you one year against manufacturing defect.

4 Q: :What' s your normal delivery time?

A: 10-25 days against down payment (exclude the official holiday)

5 Q:How about after-sales?

A:We have a large after-sale service team. All the technicians are very experienced, they always go to different countries to serve customers like you.