- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

1 T

-

Power (kW):

-

180

-

After-sales Service Provided:

-

No overseas service provided

-

Max Temperature:

-

1700.C

-

Constant temperature zone:

-

1000mm

-

Length size(mm):

-

3000mm

-

Application:

-

Heating treatment for ceramic tiles/bricks

-

Width size(mm):

-

350mm

-

Heating elements:

-

Silicon carbide(SIC)

-

Power:

-

180KW

-

Thermocouple:

-

S type

-

type:

-

roller kiln for ceramic tiles

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Luwei

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

1 T

-

Power (kW):

-

180

-

After-sales Service Provided:

-

No overseas service provided

-

Max Temperature:

-

1700.C

-

Constant temperature zone:

-

1000mm

-

Length size(mm):

-

3000mm

-

Application:

-

Heating treatment for ceramic tiles/bricks

-

Width size(mm):

-

350mm

-

Heating elements:

-

Silicon carbide(SIC)

-

Power:

-

180KW

-

Thermocouple:

-

S type

-

type:

-

roller kiln for ceramic tiles

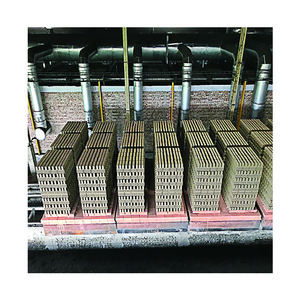

Continuous Production Electric Ceramic Automatic Roller Kil for bricks/heating treatment with 1000.

Heat Treatment muffle Furnace Laboratory Heating Equipments Working Temp : 11

Usage :

Mainly used in the production of ceramic tiles and other ceramic building materials.It is continuous heating and working, it is made by the rotation of the ceramic tube as the roller kiln vehicle the ceramic tiles or bricks materials in the kiln inner chamber.The rotation of the ceramic tube with high temperature(high-alumina),or SiC depending on the calcination temperature and ar driven by independent controller.Products are conveyed through preheating,calcinating and cooling zones on rotating rollers and are placed on selters according to the shape and dimensions.Products are heated uniformly by the upper and lower heaters(electric resistance wires,silicon carbide(SIC) or silicon molybdenum rods(MoSi2)

The temperature Category: 1000 ° C 1200 °C 1400 °C 1600 °C 1700 °C 1800 °C different kinds.we support OEM Orders for you!

|

Model |

KSS-1000 |

|

Chamber Size(L*W*H) |

5000*300*100mm Can customize |

|

Preheating zone |

1500mm Can customize |

|

Heating zone |

2000mm Can customize |

|

Cooling down zone |

1500mm Can customize |

|

Working Temp |

950°C |

|

Max Temp |

1000°C Can customize |

|

Heating Rate |

1 °C/h to 40 °C/min adjustable |

|

Temperature Accuracy |

+/-1°C |

|

Temperature Controller |

30 steps programmable and auto control |

|

Thermocouple |

S Type |

|

Heating Element |

Silicon carbon rods(SiC) |

|

Refractory |

Imported high purity alumina fiber |

|

Working Voltage AC |

AC 220V/380,50/60 Hz (or according to your requirements) |

|

Max. Power |

65KW |

|

The Furnace Materials |

Imported Morgan materials |

|

Furnace sturcture |

Double shell steel case with air cooling . |

Furnace Chamber Standard Size:

|

Chamber size/Inner size(Wx Hx D mm) |

|

3000x250x100 mm (Customized) |

|

3500x250x150 mm (Customized) |

|

4000x250x100mm (Customized) |

|

4500x350x70mm (Customized) |

|

5000x350x100mm (Customized) |

|

6000x250x150mm (Customized) |

|

7000x350x100mm (Customized) |

|

8000x350x150mm (Customized) |

|

10000x350x100mm (Customized) |

|

15000x350x100mm (Customized) |

Lab Muffle Furnace Laboratory Heating Equipments Chamber size(mm) 200x200x200 Lab Muffle Furnace Laboratory Heating Equipments Power : 8KWMuffle Furnace Laboratory Heating Equipments Thermoco Heat Treatment muffle Furnace Laboratory Heating Equipments Net weight(Kgs) 35 Lab Muffle Furnace Laboratory Heating Equipments Chamber size(mm)

Lab Muffle Furnace Laboratory Heating Equipments Chamber size(mm) 200x200x200