- Product Details

- {{item.text}}

Quick Details

-

Power:

-

550w

-

Weight:

-

45

-

Dimension(L*W*H):

-

As Per Model Customized

-

Material:

-

Stainless Steel 304/Carbon Steel/Stainless Steel 316

-

Screen Mesh:

-

2-800 mesh

-

Surface Treatment:

-

Mirror Polished

-

Technical support:

-

On-line remote guide

-

Function:

-

Screen/Separation/Sorting/Sieving

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

RUNNEST

-

Voltage:

-

220V

-

Power:

-

550w

-

Weight:

-

45

-

Dimension(L*W*H):

-

As Per Model Customized

-

Material:

-

Stainless Steel 304/Carbon Steel/Stainless Steel 316

-

Screen Mesh:

-

2-800 mesh

-

Surface Treatment:

-

Mirror Polished

-

Technical support:

-

On-line remote guide

-

Function:

-

Screen/Separation/Sorting/Sieving

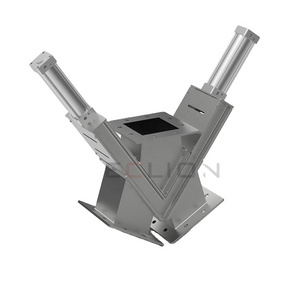

Product Introduction

The tapping sieve shaker is used for precise screening, filtration, and detection of the particle size structure, liquid solid content, and impurity content of granular and powdered materials. It’s widely used in scientific research, production, laboratories, and quality inspection rooms in departments such as geology, cement, metallurgy, powder, chemical, pharmaceutical, building materials, and national defense. The tapping sieve shaker features multiple functions. It’s suitable for checking the particle size composition of ordinary abrasives, grading the production of superhard materials, and analysis of particle size composition, such as grinding powder, silicon powder, grass carbon particles, aluminum hydroxide, ore, coal, abrasives, quartz sand, sand, activated carbon, tungsten powder, polypropylene, glaze, soil, diamond and other materials. It has the advantages of low noise, standard sieve body, high efficiency and accuracy in screening and filtering samples.

Working Principle

The tapping sieve shaker motor drives the gear to be transmitted to the main shaft through a synchronous belt. After the gear is changed, the main shaft rotates at the required speed. The main shaft drives the eccentric wheel to move the sliding plate back and forth, driving the test sieve shaker installed in the sliding plate tray to shake left and right. At the same time, the main shaft drives the top rod gear to rotate. After the speed is changed, the top rod gear hits the top rod through the cam. The top rod causes the hammer to strike the upper cover of the test sieve up and down, resulting in the reciprocating and up and down vibration of the materials in the test sieve and sample sieve, sieving the material particles smaller than the mesh holes on the test sieve into the lower test sieve. So layer by layer filtering. Only materials with the same particle size are left in each layer of the test sieve to complete material screening.

Product Details

Features:

1. Two dimensional motion with blockage: horizontal circular motion and vertical tapping motion, preventing materials from getting stuck in the sieve holes, resulting in faster and smoother discharge.

2. Equipped with a 99 minute digital timer with a tolerance of 0.1 seconds, it can achieve consistent and reproducible results, which is more reproducible than manual screening.

3. It can accommodate 1 to 8 sieves (including the bottom of the sieve) and can continuously sort a sample into 7 different particle sizes.

4. Using gears to drive synchronous belt transmission, the speed ratio is effective, ensuring consistent screening motion at the same time each time.

5. Strong stability; Adopting gear driven "synchronous belt" transmission method, with good transmission accuracy and consistency; The speed ratio is accurate and will not cause speed drop or slipping. The equipment is equipped with a digital display timer, which automatically stops when the time is set.

6. Low maintenance and repair costs; Due to the use of a "synchronous belt" to connect the two gears, the gears will not wear out and have a long service life (maintenance only requires replacing the "synchronous belt"). The eccentric wheel adopts an integral method, which is easy and accurate to install. The bearings used in the transmission part are standard parts that are not easy to wear out, have low cost, and are easy to replace.

7. High screening efficiency; The screening method has three types of movements: back and forth, swing, and vibration, which will not block the screen surface and can quickly screen the material.

8. Small size, clean, and easy to operate; Each function can be operated separately on the operation panel.

1. Two dimensional motion with blockage: horizontal circular motion and vertical tapping motion, preventing materials from getting stuck in the sieve holes, resulting in faster and smoother discharge.

2. Equipped with a 99 minute digital timer with a tolerance of 0.1 seconds, it can achieve consistent and reproducible results, which is more reproducible than manual screening.

3. It can accommodate 1 to 8 sieves (including the bottom of the sieve) and can continuously sort a sample into 7 different particle sizes.

4. Using gears to drive synchronous belt transmission, the speed ratio is effective, ensuring consistent screening motion at the same time each time.

5. Strong stability; Adopting gear driven "synchronous belt" transmission method, with good transmission accuracy and consistency; The speed ratio is accurate and will not cause speed drop or slipping. The equipment is equipped with a digital display timer, which automatically stops when the time is set.

6. Low maintenance and repair costs; Due to the use of a "synchronous belt" to connect the two gears, the gears will not wear out and have a long service life (maintenance only requires replacing the "synchronous belt"). The eccentric wheel adopts an integral method, which is easy and accurate to install. The bearings used in the transmission part are standard parts that are not easy to wear out, have low cost, and are easy to replace.

7. High screening efficiency; The screening method has three types of movements: back and forth, swing, and vibration, which will not block the screen surface and can quickly screen the material.

8. Small size, clean, and easy to operate; Each function can be operated separately on the operation panel.

Technical Parameters

|

SN

|

Item

|

Value

|

Unit

|

|

1

|

Shake times

|

290±6

|

times/min

|

|

2

|

Number of tapping

|

156±3

|

times/min

|

|

3

|

Reciprocating stroke

|

25

|

mm

|

|

4

|

Tapping height

|

38±6

|

mm

|

|

5

|

Outer diameter of sieve

|

ф200ф150ф100ф75

|

mm

|

|

6

|

Compatible sieve layer

|

1-7

|

Floor

|

|

7

|

Use voltage

|

380, 220

|

V

|

|

8

|

Output power

|

370

|

w

|

|

9

|

Dimensions

|

520*395*685

|

mm

|

|

10

|

Net Weight

|

75

|

kg

|

Certificate

About us

Application industry

Packaging and Transportation

FAQ

Q1:

What’s your production lead time?

A1: Usually our production lead time is 30 days. Depending on the your order quantity and our production schedule, the time can be shorter or longer.

Q2: Can you do OEM for me?

A2: We accept OEM orders. Please send us your logo and requirement, then we will arranged the production for you..

Q3: What's your payment terms?

A3: T/T and LC at sight are both acceptable for us. 50% advance payment, and balance paid before shipment.

Q4: What’s your MOQ?

A4: We don’t have requirement of MOQ for the order. But for order of bigger quantity, we can provide more discount.

Q5: What packages do you use for the machine?

A5:It depends on product and order qty. Normally, it takes us 15~20 days for an order with MOQ qty.

Q6: What warranty do you provide for the machine?

A6: The warranty period is one year, and we will be responsible for provision of parts or components for repair of quality

problems (except for improper operation or wearing parts) during that period. In case on-site maintenance service is required,

additional fees (such as labor cost, round-trip air ticket, accommodation, visa fee, etc.) shall be charged accordingly.

A1: Usually our production lead time is 30 days. Depending on the your order quantity and our production schedule, the time can be shorter or longer.

Q2: Can you do OEM for me?

A2: We accept OEM orders. Please send us your logo and requirement, then we will arranged the production for you..

Q3: What's your payment terms?

A3: T/T and LC at sight are both acceptable for us. 50% advance payment, and balance paid before shipment.

Q4: What’s your MOQ?

A4: We don’t have requirement of MOQ for the order. But for order of bigger quantity, we can provide more discount.

Q5: What packages do you use for the machine?

A5:It depends on product and order qty. Normally, it takes us 15~20 days for an order with MOQ qty.

Q6: What warranty do you provide for the machine?

A6: The warranty period is one year, and we will be responsible for provision of parts or components for repair of quality

problems (except for improper operation or wearing parts) during that period. In case on-site maintenance service is required,

additional fees (such as labor cost, round-trip air ticket, accommodation, visa fee, etc.) shall be charged accordingly.

Hot Searches