- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Model Number:

-

MT-LSB450-R

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

12200*6000*2500mm

-

Weight:

-

14500 KG

-

Model:

-

MT-LSB450-R

-

Bag Width:

-

260-450mm

-

Bag length:

-

L=C-(H/2+15~25)

-

Speed:

-

150pcs/min

-

Paper Thickness:

-

80-180 Gsm

-

Bottom size:

-

70-180mm

-

Paper roll width:

-

700-1300mm

-

Max reel weight:

-

800kg

-

Max roll diameter:

-

1200mm

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Paper

-

Place of Origin:

-

China

-

Model Number:

-

MT-LSB450-R

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

12200*6000*2500mm

-

Weight:

-

14500 KG

-

Model:

-

MT-LSB450-R

-

Bag Width:

-

260-450mm

-

Bag length:

-

L=C-(H/2+15~25)

-

Speed:

-

150pcs/min

-

Paper Thickness:

-

80-180 Gsm

-

Bottom size:

-

70-180mm

-

Paper roll width:

-

700-1300mm

-

Max reel weight:

-

800kg

-

Max roll diameter:

-

1200mm

Product Description

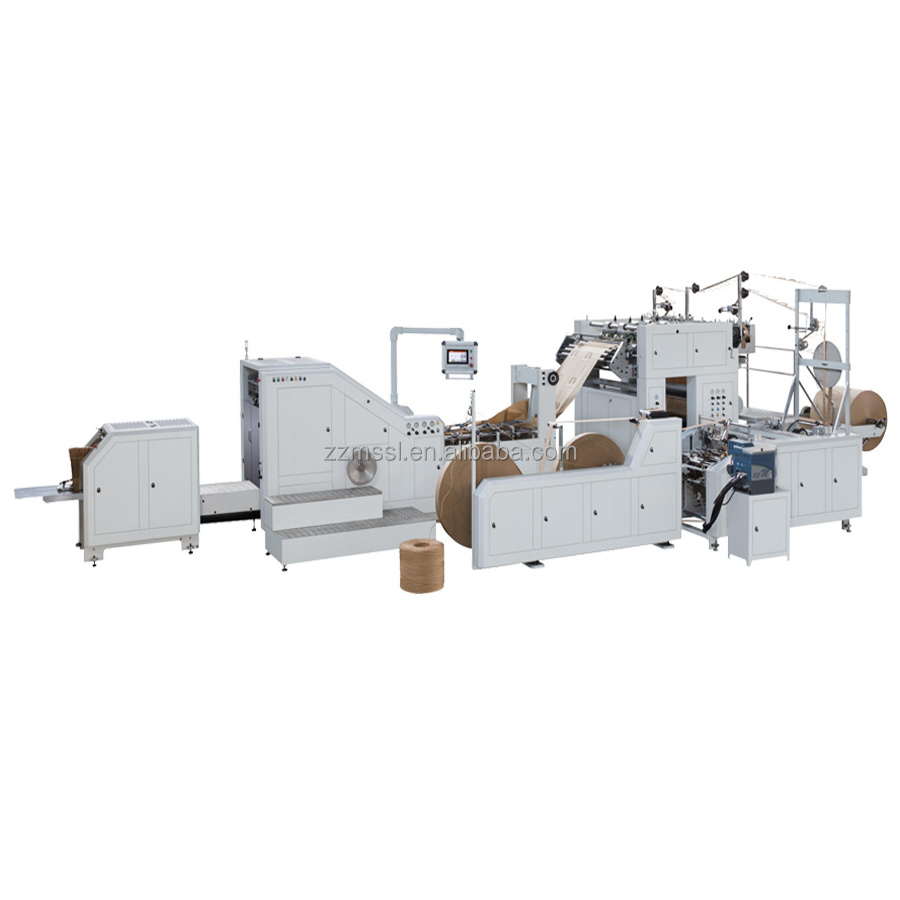

Paper Bag Making Machine with Printing/Bags Making Machine/Paper Bag Production Machine

This machine is designed to manufacture square bottom paper bags with twisted handle from paper roll, paper patch roll and paper rope. YASKAWA PLC Control system imported from Japan and adjustable dual-moulds structure, ensure that the machine can perform quickly and stably, as well as reduce adjusting time for different bag sizes. Front bags collection platform and counting function, improve packing efficiency of paper bags packing. By implementing steps including handle making. handle application, tube forming, tube cutting, and bottom forming with a fully automatic process. That is especially suitable for foodstuff, clothing and luxury branding products.

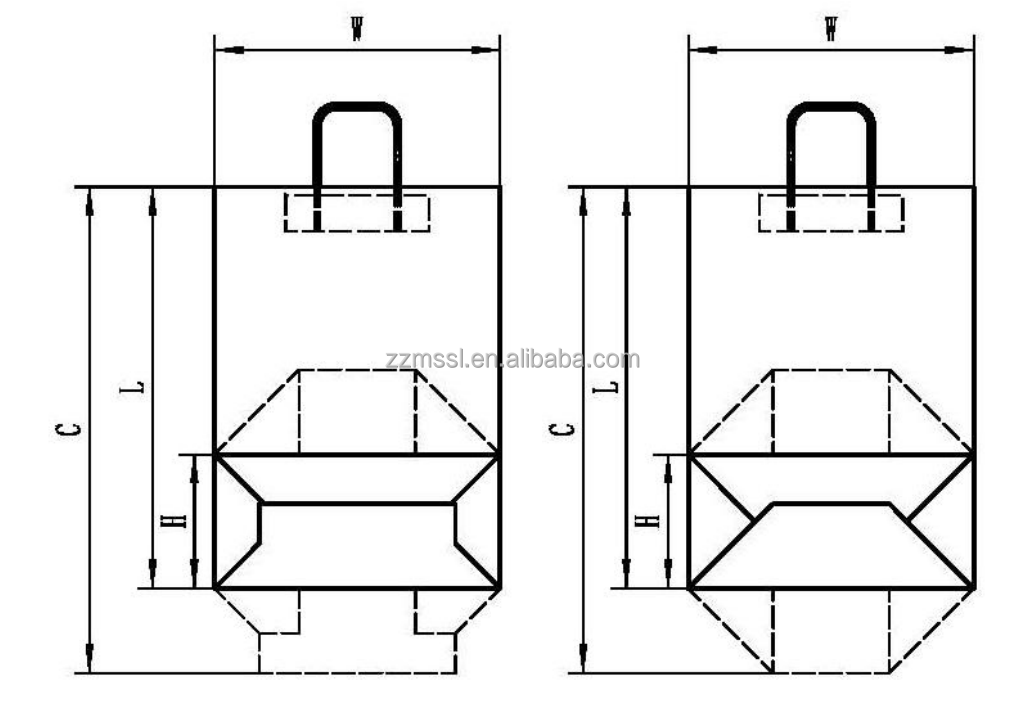

Specification

|

Model

|

MT-LSB450-R

|

|

Bag width(W)

|

260--450mm

|

|

Bottom size(H)

|

70-180mm

|

|

Cutting length(C)

|

270-530mm(NO HANDLE), 270-430mm(with handle)

|

|

Bag length(L)

|

L=C-(H/2+15~25)

|

|

Max speed

|

150pcs/min

|

|

Paper roll width

|

700-1300mm

|

|

Max reel weight

|

800kg

|

|

Max roll diameter

|

1200mm

|

|

Reel Inner diameter

|

76mm(3inch)

|

|

Paper thickness

|

80-180gsm

|

|

Handle Rope Height

|

100mm

|

|

Handle rope diameter

|

4-6mm

|

|

Paper rope spacing

|

95.2mm

|

|

Handle patch length

|

190.5mm

|

|

Handle patch width

|

40-50mm

|

|

Paper patch roll width

|

80-100mm

|

|

Paper patch thickness

|

100-150gsm

|

|

Web edge control system

|

Double photoelectric automatic correction control system

|

|

Web tension control system

|

Automatic constant tension control system

|

|

Air pressure

|

0.6-1.2Mpa

|

|

Driven motor

|

Seven servo motors

|

|

Voltage

|

380V,50Hz,3phase

|

|

Power

|

27KW

|

|

Weight

|

14500kg

|

|

Dimension

|

12200*6000*2500mm

|

Details Images

Adopt Japanese original Yaskawa servo control system to realize high-speed and precise operation control

Touch Screen and Motion Control System

Adopt touch screen and Motion Control System, the work condition can be shown real time. Cooperate with the ultra precise double servo motor, the stability can be guaranteed.

Pneumatic Paper Reel Lifting Device

Pneumatic paper reel lifting device make paper reel changing easy. Press one switch and the paper reel will be lifted automatically.

Automatic Edge Control System

Automatic edge control system adopts two photoelectric sensors to detect the edge of paper web. The motor doesn't need to work often so its power consumption is reduced and its life is extended.

Precise Color Mark Tracing System

Precise color mark tracing system can make sure precision of bag printing pattern cutting position. The color mark tracing function can avoid the readjustment after paper reel changing, paper web breaking, or power outage.

Integral Tube Forming Adjustment Structure

The integral tube forming adjustment structure can be adjusted at the same time on one side or both sides to improve work efficiency, reduce the scrap rate generated by the adjustment process, and save adjustment time and stability of adjustment.

Compact Mechanical

Transmission

Design

The compact design of mechanical transmission, ensure that the material is passed stable, accurate, improving mechanical properties, producing paper bags better appearance, neat.

Width-adjustable Paper Handle Convey

Width-adjustable paper handle conveying structure can adjust the width according to the paper handle, which makes the paper handle more applicable.

Independent Servo Gluing System

The gluing position of the paper handle can be adjusted arbitrarily, and the gluing position can be adjusted as you like.

The machine has automatic counting system. The user can set a number to count. When bag quantity meets the number, the bag will be jumped out like the picture shows.

Finished Products

Recommend Products

Packing & Delivery

Hot Searches

![[JT-HY330] Machine for Making Kraft Paper Bag / Paper Bags Production Machine / Craft Paper Bag Making Machine](https://cdn.bestsuppliers.com/seo_products_img/jeta/22c65a5d5893304db66b95efbe1aaf82.jpg!/rotate/180/sq/300)