- Product Details

- {{item.text}}

Quick Details

-

Tensile strength:

-

>1100MPA

-

Grade:

-

Q195;Q304

-

Shape:

-

Crimped

-

Application:

-

Concrete Reinforcement

-

Advantages:

-

Excellent Tensile, High Tenacity,Against Cracking

-

Surface treatment:

-

Black or Metallic Color or Copper Coated

-

Certificate:

-

ISO9001

-

Length:

-

6-100mm

-

Key Word:

-

Metal Fiber

-

Flat Ends Steel Fiber Metal Fiber:

-

Concrete Reinforcing Building Materials

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Hongda

-

Model Number:

-

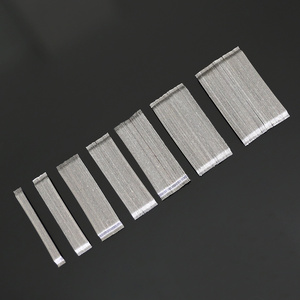

Flat End Steel Fiber

-

Tensile strength:

-

>1100MPA

-

Grade:

-

Q195;Q304

-

Shape:

-

Crimped

-

Application:

-

Concrete Reinforcement

-

Advantages:

-

Excellent Tensile, High Tenacity,Against Cracking

-

Surface treatment:

-

Black or Metallic Color or Copper Coated

-

Certificate:

-

ISO9001

-

Length:

-

6-100mm

-

Key Word:

-

Metal Fiber

-

Flat Ends Steel Fiber Metal Fiber:

-

Concrete Reinforcing Building Materials

- Waterproof concrete by 85%

- Chemically inert, resists cement and aggregates

- It increases impact resistance

- Low electric Insulator (nonmagnetic)

- Floor plates combat warping

- Works three-dimensionally

- Increased fire resistance of polypropylene microfibers

- Cheaper than mesh

- Increases the flexural tenacity

- High adhesion to concrete It increases cohesion and reduces segregation

- Being stainless ensures its durability

- Reinforcing capacity equal or more than steel

- Minimizes hose wear, pumps and mixers tops.

- Minimizes the risk of accidents by sticks with steel wires .

- Simplifies transport costs

HOW TO APPLY MACROFIBER:

Our fiber has previously been packed into bags or cartons. In 1 cubic meter of concrete (M3), 8 bags of cement is used. It all depends on the desired degree of quality according to the standard and resistance related to compression tests on samples of concrete at 28 days. Mostly one deck is used 5.47 oz (156 grams) of fiber per sack of cement from 80 to 94 lbs. Disperse each deck slowly as cement, sand and stone aggregate (if any). In concrete mixers, disperse few "bundles" as needed per m3 in the conveyor belt slowly.

TECHNICAL DATA SHEET

|

Types |

Diameter(mm) |

Length(mm) |

Tensile Strength(Map) |

|

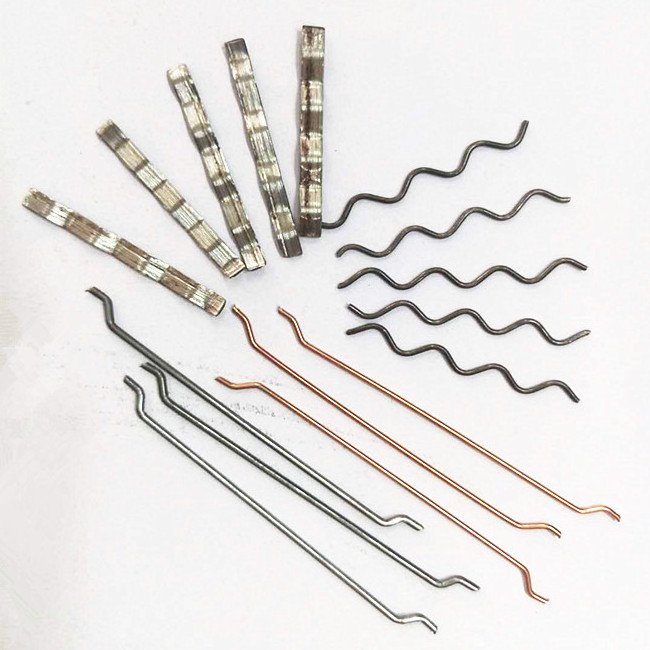

Hooked ends steel fiber |

0.5-1.0 |

30-60 |

>1100 |

|

Copper coated steel fiber |

0.5-1.0 |

30-60 |

>1100 |

|

Glued steel fiber |

0.5-1.0 |

30-60 |

>1100 |

|

Wavy steel fiber |

0.5-1.0 |

30-60 |

>1100 |

|

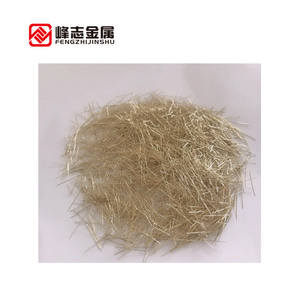

Milling steel fiber |

/ |

30-60 |

>1100 |

|

Or according to customer ’ s requirement

|

|||