- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/415V/600V

-

Dimension(L*W*H):

-

1300*1100*1200mm

-

Weight:

-

310 kg

-

Product name:

-

Animal floating fish feed mill shrimp food pellets extruder machine

-

Application:

-

Make Animal Feed

-

After-sales Service Provided:

-

Video Technical Support

-

Raw material:

-

Wheat Bran

-

Capacity:

-

150---2000kg/h

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Final product:

-

Pellet Food

-

Pellet size:

-

2-12mm

-

Material:

-

Durable Carbon Steel

-

Usage:

-

Animal Poultry Livestock Feeding

Quick Details

-

Max. Capacity:

-

100kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SHENGHONG

-

Voltage:

-

380V/415V/600V

-

Dimension(L*W*H):

-

1300*1100*1200mm

-

Weight:

-

310 kg

-

Product name:

-

Animal floating fish feed mill shrimp food pellets extruder machine

-

Application:

-

Make Animal Feed

-

After-sales Service Provided:

-

Video Technical Support

-

Raw material:

-

Wheat Bran

-

Capacity:

-

150---2000kg/h

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Final product:

-

Pellet Food

-

Pellet size:

-

2-12mm

-

Material:

-

Durable Carbon Steel

-

Usage:

-

Animal Poultry Livestock Feeding

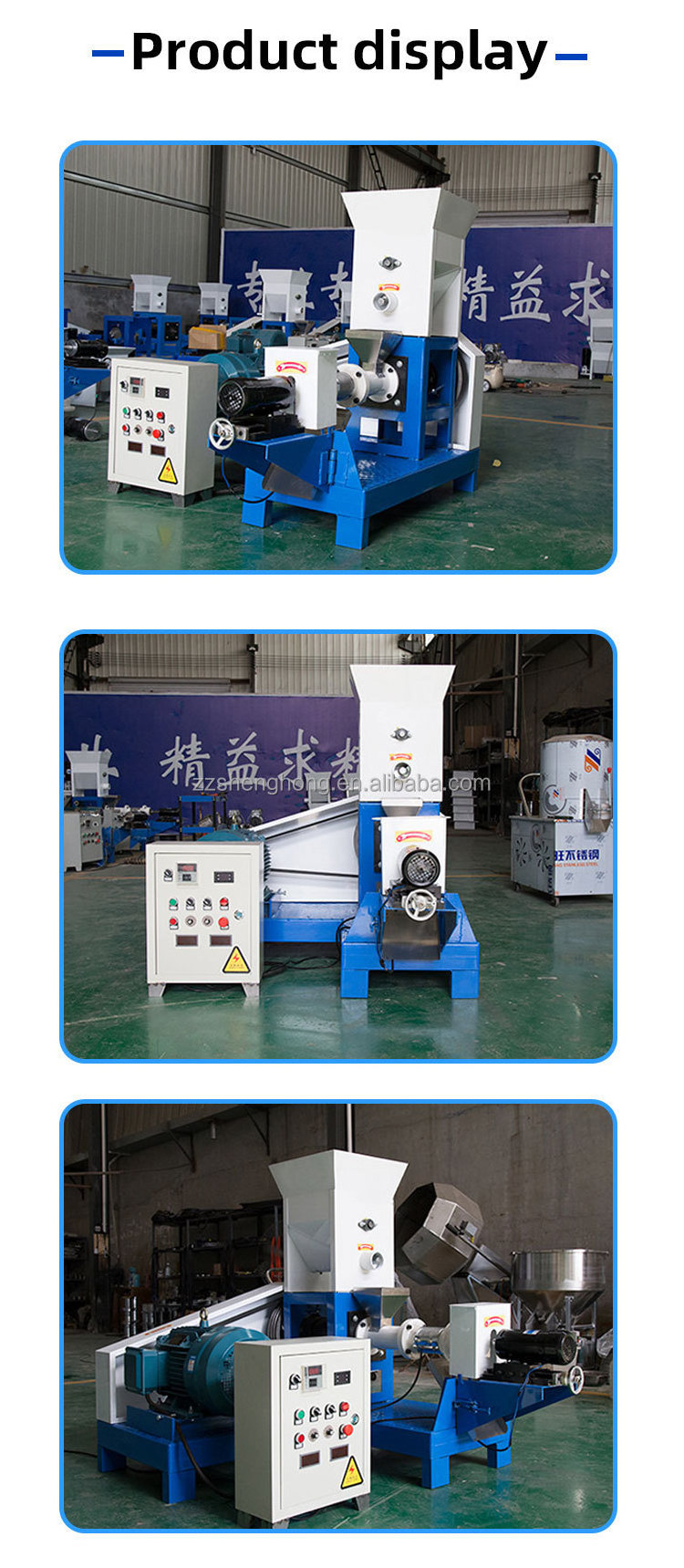

Animal floating fish feed mill shrimp food pellets extruder machine

Pellet feed extruding equipment can produce a variety of flower shapes, and molds can be customized according to requirements. The product outlet is equipped with a rotary cutting device with variable frequency speed regulation, which can adjust the rotation speed of the blade to control the cutting speed and length. This equipment uses corn, soybean (bean cake) animal scraps as raw materials, and can be expanded into the machine to produce different particle shapes. It is suitable for dogs, cats, fish, birds, rabbits, shrimps, dogs, cats, mink, fox, etc.

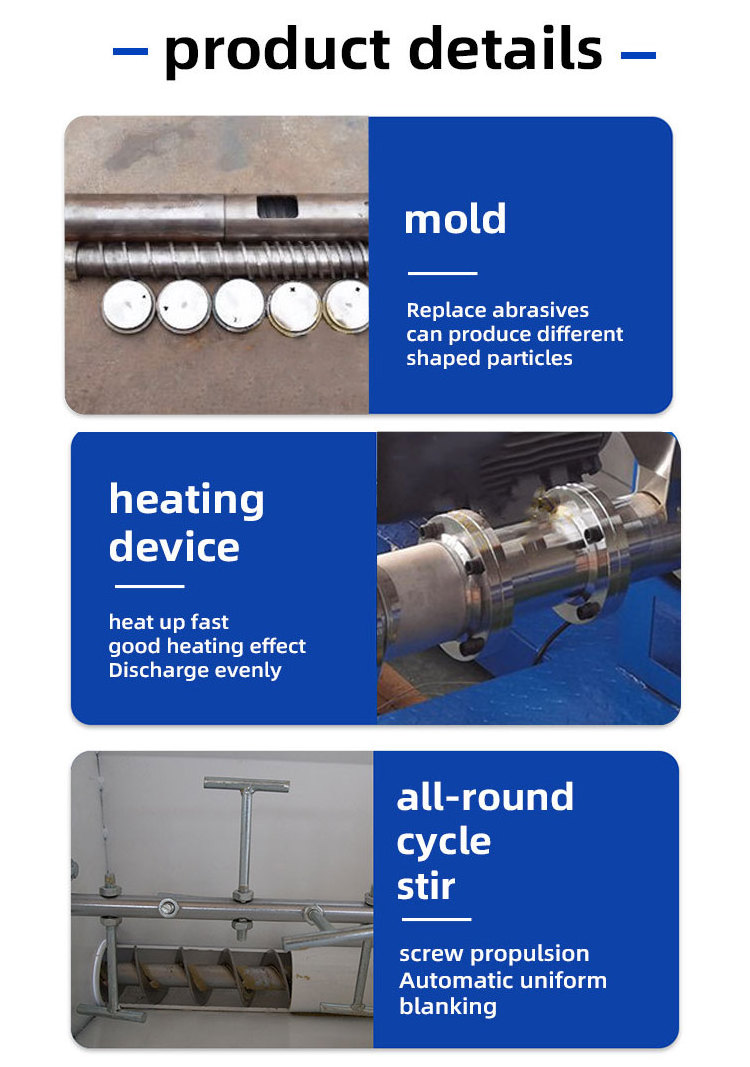

1. The industry standard pelletizing structure adopts the form of soft knife to realize stepless speed change, and can cut the output material into products of required length arbitrarily, and it is not easy to produce burrs.

2. Novel and unique design, simple structure, easy to install, easy to disassemble, easy to operate.

3. The screw sleeve and screw are made of special wear-resistant and high-temperature alloy steel materials, which are formed by heat treatment, and have the advantages of wear resistance and long service life.

4. Equipped with a unique pressurized die device to ensure feed output and quality; and equipped with an electric heating device to improve the feed expansion rate.

5. The main motor adopts high-quality Y series three-phase motor to ensure strong power.

6. The speed-adjusting feeding device is more convenient to operate, the feeding is uniform, and the machine is prevented from being stuck.

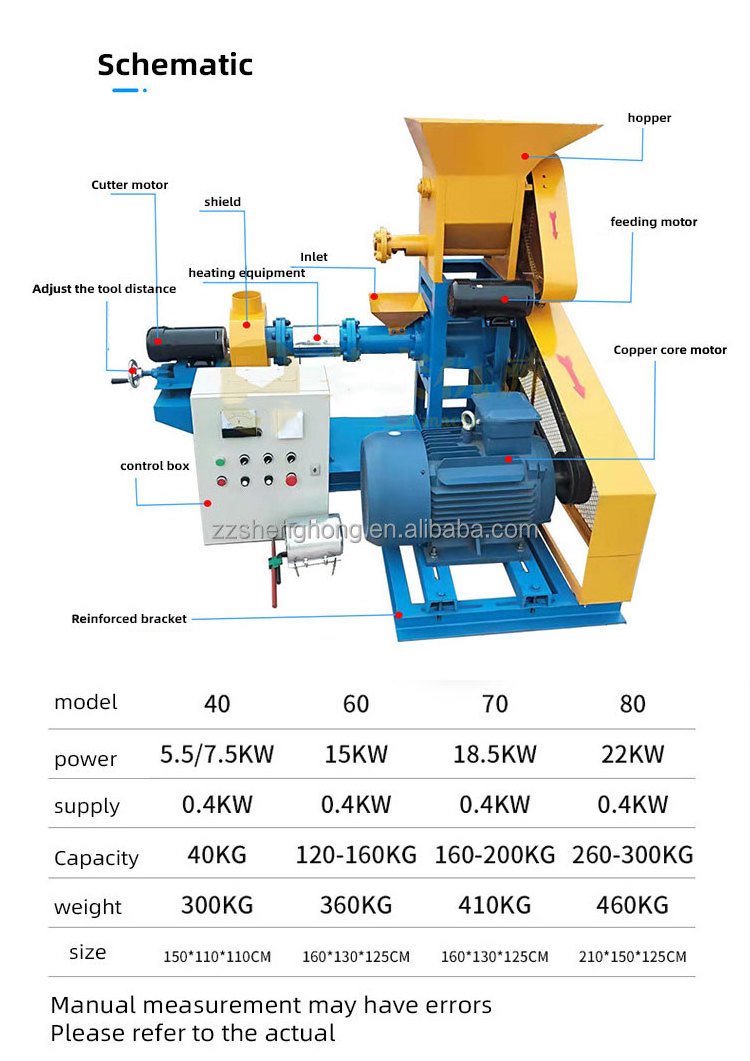

| Model | Power(kw) | Capacity(t/kg) | Feeding power(w) | Cutting power(W) | Weight(kg) | Dimension(mm) |

| DGP40 | 5.5-7.5 | 40-50 | 400 | 400 | 310 | 1300*1100*1200 |

| DGP50 | 7.5-11 | 80-100 | 400 | 400 | 330 | 1350*1100*1200 |

| DGP60 | 15 | 120-150 | 400 | 400 | 360 | 1350*1100*1200 |

| DGP70 | 18.5 | 180-200 | 400 | 400 | 410 | 1500*1360*1250 |

| DGP80 | 22 | 200-240 | 400 | 400 | 460 | 1550*1450*1250 |

| DGP90 | 30-37 | 250-300 | 600 | 600 | 1300 | 1800*1650*1500 |

| DGP120 | 55 | 400-450 | 600 | 800 | 1500 | 1850*1700*1500 |

| DGP135 | 75 | 500-550 | 800 | 1100 | 1900 | 2600*1950*1600 |

| DGP160 | 90 | 1000-1200 | 1100 | 1500 | 3700 | 2900*2650*1800 |