Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Mconvey

-

Voltage:

-

Custom

-

Power (kW):

-

132

-

Weight:

-

100000 KG

-

Product name:

-

compounding extruder

-

Keywords:

-

twin screw compounding extruder

-

Pelletizing type:

-

Co-rotating Parallel Twin-screw Extrusion system

-

Function:

-

FLEXCON flexible control system

-

Extruder:

-

PP / PE / TPE / TPR ABS / PC

-

Final product:

-

plastic pellet

-

Plastic Type:

-

Modified plastic

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

40-52

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Mconvey

-

Voltage:

-

Custom

-

Power (kW):

-

132

-

Weight:

-

100000 KG

-

Product name:

-

compounding extruder

-

Keywords:

-

twin screw compounding extruder

-

Pelletizing type:

-

Co-rotating Parallel Twin-screw Extrusion system

-

Function:

-

FLEXCON flexible control system

-

Extruder:

-

PP / PE / TPE / TPR ABS / PC

-

Final product:

-

plastic pellet

-

Plastic Type:

-

Modified plastic

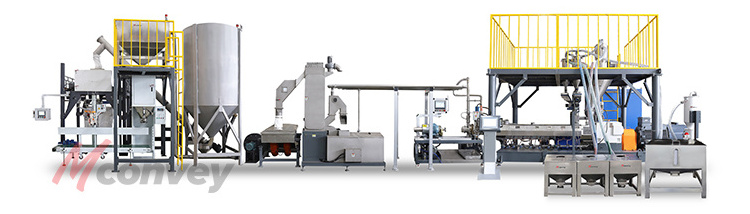

LSZS Co-rotating Parallel Twin-screw

Mixing And Dosing Extrusion System

Extruder Model

C series:6-9Nm/cm³

| No. | Type | L/D ratio | Screw speed(rpm) | Motor power(kw) | Throughput(kg/h) | Range of application |

| 1 | LSZS-52C | 40-52 | 600 | 75 | 200-300 | PP / PE / TPE / TPR / ABS / PC |

| 2 | LSZS-63C | 40-52 | 600 | 132 | 300-400 | |

| 3 | LSZS-72C | 40-52 | 600 | 160 | 400-600 |

M series:11-15Nm/cm³

| No. | Type | L/D ratio | Screw speed(rpm) | Motor power(kw) | Throughput(kg/h) | Range of application |

| 1 | LSZS-50M | 40-52 | 600/900 | 110/160 | 300-400 | ABS / PC / TPU / PA / PBT / PET / PPS / PPA / LCP / PEEK / PMMA |

| 2 | LSZS-58M | 40-52 | 600/900 | 160/250 | 500-600 | |

| 3 | LSZS-75M | 40-52 | 600/900 | 315/475 | 800-1000 |

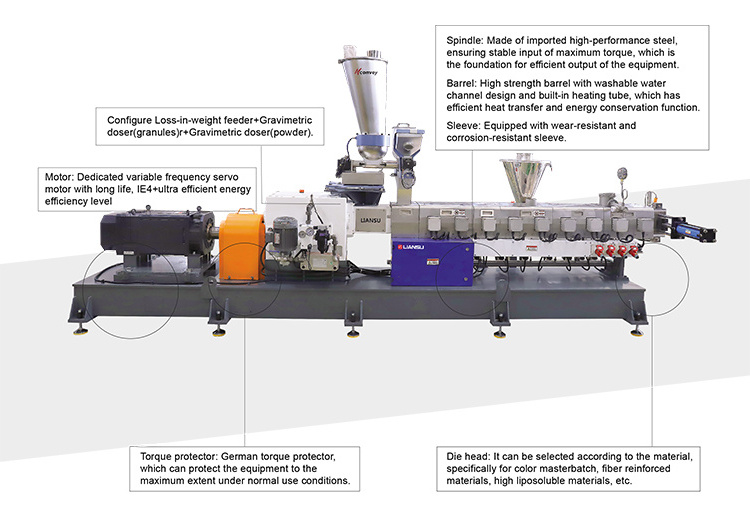

Screw Element

The screw and barrel are the plasticizing parts of the extruder, which are the core parts related to the plasticization, dispersion, and physical properties of materials. Liansu can provide professional process suggestions and suitable screw combinations based on customers' specific production requirements. In response to the wear or corrosion environment of materials, Liansu can provide professional recommendations on screw elements/barrel sleeve materials, recommending the most cost-effective material applications.

Barrel Sleeve

The heating and cooling efficiency of the barrel is also a key performance of the extruder. especially PC and ABS materials with high whiteness requirements are very sensitive to the actual effect of temperature control!

Configure online precise measurement and feeding systems for multiple materials.

* For granular or powdery materials, it can achieve multiple raw materials, and the materials can be continuously and accurately added to the extruder according to the target output of each component.

* For granular or powdery materials, it can achieve accurate measurement in batches for multiple raw materials according to the target weight of each component, and premixed before being uniformly added to the extruder.

Extrusion control system: FLEXCON + flexible control system

* Full line system control of the extruder;

* Full line data collection and related data analysis;

* Closed-loop control of feeding quantity to ensure measurement accuracy;

* Intermediate or higher-order vibration detection and analysis systems can be selected for real-time predictive maintenance of key components such as the extruder gear box, screw, and main transmission motor;

Predictive maintenance of extrusion gear box

Energy consumption analysis of production line

Product Details

FAQ

Frequently asked questions when purchasing products

Q:How old is your company? How many years of production experience do you have?

A: Our factory was established in 1994 and has 27 years of factory production experience

Q:How many years' experience do you have in export trade?

A:We have been engaged in self-export trade for more than 20 years

Q:What's your lead time?

A: For the equipment in stock, we usually deliver the goods within 7 days after payment

For equipment not in stock, 1 ordinary machine takes 7 working days

For one or more containers, it will take about 30 working days

Q:How long is the warranty?

A:The warranty period of products sold overseas shall be within 15 months from the date of leaving the factory; During the warranty period, if the product or its parts are faulty or damaged, if it is a product design defect, production quality, parts quality problem, our company provides damaged parts free of charge during the warranty period, but the failure or damage caused by human error, operation error is excluded, vulnerable parts are excluded;

Q:What are your terms of payment?

A: 100% t/T before shipment, signed l/C or paid through Alibaba Credit guarantee Trade.