- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

750

-

Voltage:

-

380

-

Current:

-

N

-

Rated Capacity:

-

N

-

Rated Duty Cycle:

-

N

-

Dimensions:

-

L1350*W1300*H1920MM

-

Use:

-

bga rework station

-

Product name:

-

Automatic Welding Robot

-

Welding Method:

-

Automation TIG Welding

-

Material:

-

Stainess Steel

-

Welding Material:

-

Mild Steel

-

After-sales Service Provided:

-

Online Service Provided

-

Application:

-

Rework BGA

-

Technology:

-

Robot Controller Technology

-

Keyword:

-

Laser Welder

-

Advantage:

-

Touch Screen

-

Positioning:

-

Direction

Quick Details

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

China

-

Brand Name:

-

WDS

-

Weight (KG):

-

750

-

Voltage:

-

380

-

Current:

-

N

-

Rated Capacity:

-

N

-

Rated Duty Cycle:

-

N

-

Dimensions:

-

L1350*W1300*H1920MM

-

Use:

-

bga rework station

-

Product name:

-

Automatic Welding Robot

-

Welding Method:

-

Automation TIG Welding

-

Material:

-

Stainess Steel

-

Welding Material:

-

Mild Steel

-

After-sales Service Provided:

-

Online Service Provided

-

Application:

-

Rework BGA

-

Technology:

-

Robot Controller Technology

-

Keyword:

-

Laser Welder

-

Advantage:

-

Touch Screen

-

Positioning:

-

Direction

Our BGA Rework Station/ BGA reballing station are widely used to replace and repair the BGA chip in laptop, mobile phone,xbox360,ps3,etc.

The main user is repairing shops and factory to provide the after-sales service and rework.

Main Features

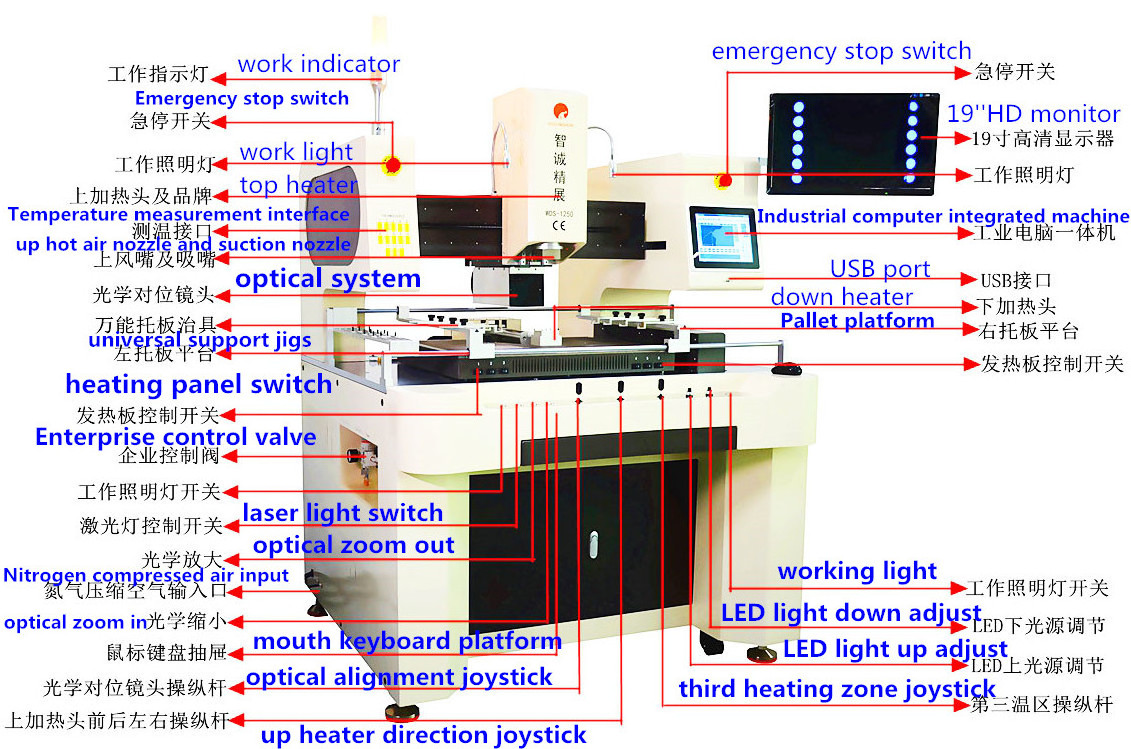

♦Independent ten axis interlock,ten electric motor drive control all movement.Up&down temperature zone/PCB movement and optical alignment system X/Y movement all can control by computer,easy operation.Machine can store more than 100 temperature profile,suit for large quantities motherboard rework,increase the work efficiency,high-level automatic;

♦heat and mount head design 2 in 1,which can auto rotate,mount,soldering and auto remove function;

♦Independent three temperature zone(upper&lower&infrared preheater zone),upper and lower temperature zone can auto move,can automatically reach any place on the infrared preheater zone.Down temperature can be up and down movement,support PCB,using motor auto control. PCB in the fixture not move, up and down heating head can move to any chip place on the PCB.

♦X, Y direction of movement and the overall unique design, making the equipment space is fully utilized to a relatively small size of equipment to achieve large area PCB rework, the maximum clamping plate size up to 1200*700mm, no rework dead ends;

♦Built-in vacuum pump, Φ-axis arbitrary rotation, high-precision stepper motor control, automatic memory function, precision fine-tune nozzle;

♦Color high-definition optical system,with color-difference resolution, auto focus, software operating functions, 22x optical zoom, rework Maximum BGA size 120 *120mm;

♦IPC+PLC control,embedded IPC,touch screen operation interface.PLC control,display temperature curve immediately, show setting curve and measured curve,can analyze the measured temperature curve.

♦10sections up(down) temperature+10sections constant temperature,can store more than 100 group temperature curve, can analysis the temperature curve on the touch screen;different sizes Titanium alloy nozzles,easy change,can 360°rotate.

♦13 pcs temperature sensor, can monitor and analysis more place on the PCB.Equipped with nitrogen inlet, use nitrogen to protect the soldering,more the rework more safety and reliable.

♦Suction rod with manual flow cool down system,on BGA reworking process,it can cool down chip surface at any time.It will decrease temperature difference,efficiently protect chip avoid to damage by high temperature;

♦High sensitive touch screen IPC control,intelligent operation system. It can remote-control after networking.

How to separate BGA chip from motherboard?

How to replace a new BGA chip?

Repair steps:

1) Separate the BGA chip from motherboard –we called desoldering

2) Clean Pad

3) Reballing or replace a new BGA chip directly

4) Alignment/Positioning – Depend on experience ,silk frame ,optical camera

5) replace a new BGA chip - we called Soldering

Product Paramenters

| Power supply | AC 380V±10% 50/60Hz |

| Total power | 16000W |

| Heater power | Upper temp.zone 1200W,second temp.zone 1200W,IR temp.zone 8000W |

| Electrical material | High sensitive touch screen+temperature control module+PLC+step driver |

| Temperature controlling | High precision K shape sensor(Closed Loop),up and down independent temperature heating zone,Precision can reach±1℃ |

| Locating way | V shape holder&universal jigs |

| PCB size | Max1200×700mm Min 10×10 mm |

| Applicable chips | Max120×120mm Min 0.6×0.6mm |

| PCB thickness | 0.3-8mm |

| Mounting BGA weight | 300G |

| Mounting precision | ±0.01mm |

| Thermo-couple Ports | 13 pcs |

| Weight of machine | 750KG |

| Alignment system | Optical lens+HD industrial camera |

| Tin point monitoring | Side camera used for monitoring solder ball melting in soldering process |

1,Standard export strong wooden package for bga rework station

2,Delivery in

2 workdays

after payment confirm;

PCB BGA chips rework station

3,Shipping by

TNT, UPS ,DHL,FEDEX (IE), or by air or by sea

4,Loading Port:

ShenZhen

or

Hongkong